+13

Digz

Nightmoves

RodStRace

savage

itruns

Kakster

ViewMaster

BvrWally

m1dadio

donivan65

mo_1040

sasktrini

Scott

17 posters

All Systems STOPPED...

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°126

Re: All Systems STOPPED...

Re: All Systems STOPPED...

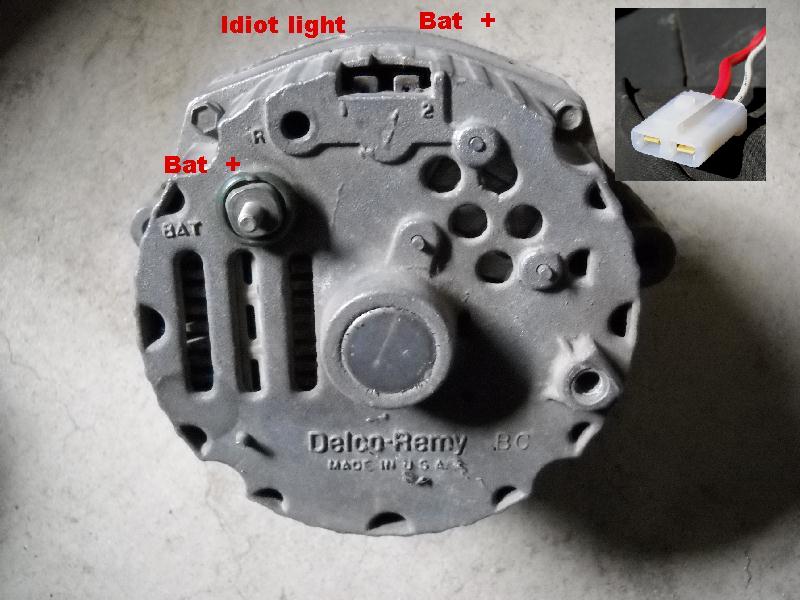

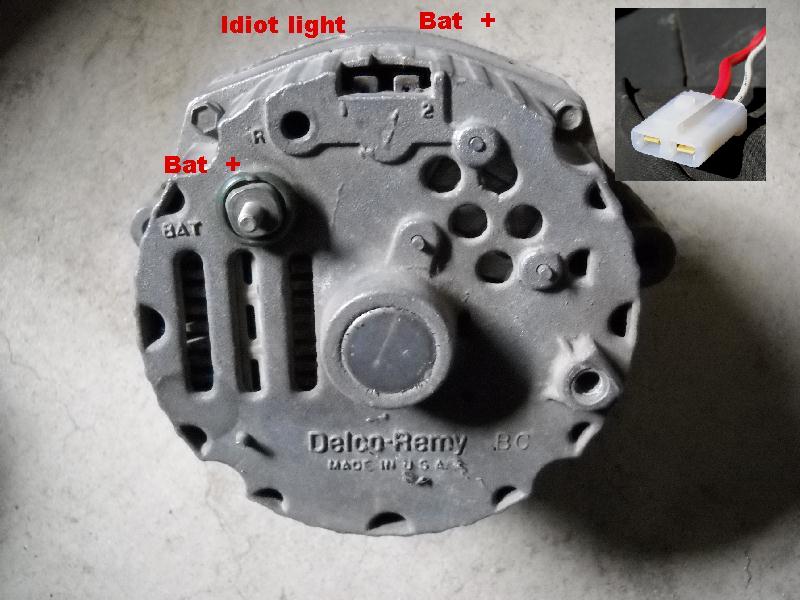

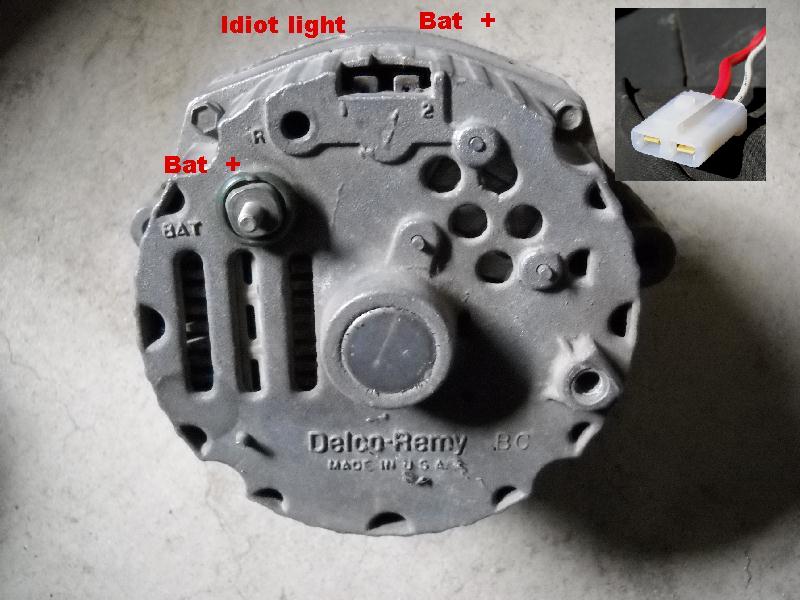

Do a search Scott,,,,,,,or if you need it this year,,,,,,connect the # 4 wire from the voltage regulator connector to the #1 terminal on the Alternator,,,,,#2 on the alternator COULD go to the output on the alternator,,,,,it is the sensing line for the regulator inside,,,,,BUT,,,,,,,I like to run it to the battery cable on the starter solenoid SO IT ACTUALLY SENSES THE BATTERY VOLTAGE,,,,,,,,and run at least a 10 gauge wire from the output to the same place

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°127

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I dug around and couldn't find it. I'm sure I've asked the question before, but asked long before I got to it.

Voltage Regulator

F = Blue ==> No Longer Needed

2 = White ==> No Longer Needed

3 = Red ==> No Longer Needed

4 = Brown ==> #1 Terminal on Alternator

Alternator

#2 (Sensing Line) ==> Battery cable on the Starter Solenoid so it actually senses the battery voltage

BAT ==> Battery cable on the Starter Solenoid (10 gauge)

So I don't do anything with the rest of the Voltage Regulator wires since those are now hard wired inside the Alternator..?

There's also a bolt on the back of the Alternator for a ground wire. It seems like overkill to me since it is bolted to the engine.

Thanks again for your help Donivan.

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°128

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I knew you were not going to find anything in using search,,,,,,but to get a little more technical,,,,,,the F and 2 wires in that voltage regulator just go to the F and R terminals on the original alternator,,,,,rip them out,,,,,#3 in that connector goes to one of the screws on the horn relay,,,,,,rip it out,,,,,,,# 4 comes from the idiot light,,,,,,,move it to the#1 terminal on the alternator,,,,,,,thats the plan,,,,,,you might have a little different set up,,,,,,,,,

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°129

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Do you think I should put a Fusible Link on the output connector of the Alternator?

Can the Sensing Line back to the Starter Solenoid can stay the same 20 Gauge wire? Should I put a Fusible Link on this line too?

Can the Sensing Line back to the Starter Solenoid can stay the same 20 Gauge wire? Should I put a Fusible Link on this line too?

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°130

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Anything that is hot all the time needs a Fusible Link to protect the circuit,,,,,,,,and the 2nd Gens have a fusible link at the wire that feeds the van at the starter solenoid. So originally you were protected,,,,,,But as you add other equipment, you have the possibility of overloading that fusible link. SO,,,,,,,good insurance is to add another fusible link to that alternator output and you can leave the other circuits protected by the original fusible link. But you can't have enough fusible links, so if 1 circuit shorts out, it does not kill all the other circuits tied to that fusible link and leave you stranded. That sensing line does not need a bigger wire at all,,,,,,,,,

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°131

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Finished most of the wiring today, but have a new question.

Is there anything to the engine not shutting off when I turn off the key because of this new Alternator? The Speedway catalog has the Alternator plug listed, but they added something that would prevent the engine from running even after the key was shutoff. Is that them selling to people that don't know better, or do I need to add something?

I also want to run both the oil pressure / water temp dash lights, but also gauges. The lights get attention much quicker, but then I want the gauge to reference. I installed a mechanical oil pressure gauge, but had to remove the light sensor, is there another place on the 250 block for an oil pressure sensor, or do you know where I can find a T connector?

Same problem with the water sensor. The old engine had a place in the head for a water sensor, this now head doesn't have that hole. Instead the new engine has a place where the radiator hose hooks, but only one, and I want to run both sensors.

Is there anything to the engine not shutting off when I turn off the key because of this new Alternator? The Speedway catalog has the Alternator plug listed, but they added something that would prevent the engine from running even after the key was shutoff. Is that them selling to people that don't know better, or do I need to add something?

I also want to run both the oil pressure / water temp dash lights, but also gauges. The lights get attention much quicker, but then I want the gauge to reference. I installed a mechanical oil pressure gauge, but had to remove the light sensor, is there another place on the 250 block for an oil pressure sensor, or do you know where I can find a T connector?

Same problem with the water sensor. The old engine had a place in the head for a water sensor, this now head doesn't have that hole. Instead the new engine has a place where the radiator hose hooks, but only one, and I want to run both sensors.

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°132

Re: All Systems STOPPED...

Re: All Systems STOPPED...

If you are building a Hot Rod from scratch or ordering from a Hot Rod shop, you need several things to make non standard stuff to work together. One thing would be stop the alternator from feeding back into the ignition switch after the key was turned off,,,,,,,basically sending voltage back into the system. BUT,,,,,,,,the idiot light has a resistance wire built into it , so if you plug that idiot light wire into the #1 terminal on an internal regulator 3rd Gen alternator, you are good to go,,,,,if you aint got no idiot light,,,,,you need to put a 10 ohm resistor in that line to the #1 terminal. As for the senders,,,,,the oil light is easy,,,,,you put in a 1/8" brass pipe nipple and a T and hook both oil pressure senders in it,,,,,,, The temp senders can be in the thermostat housing and the lower housing below the thermostat,,,,,,which one do you have?

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°133

Re: All Systems STOPPED...

Re: All Systems STOPPED...

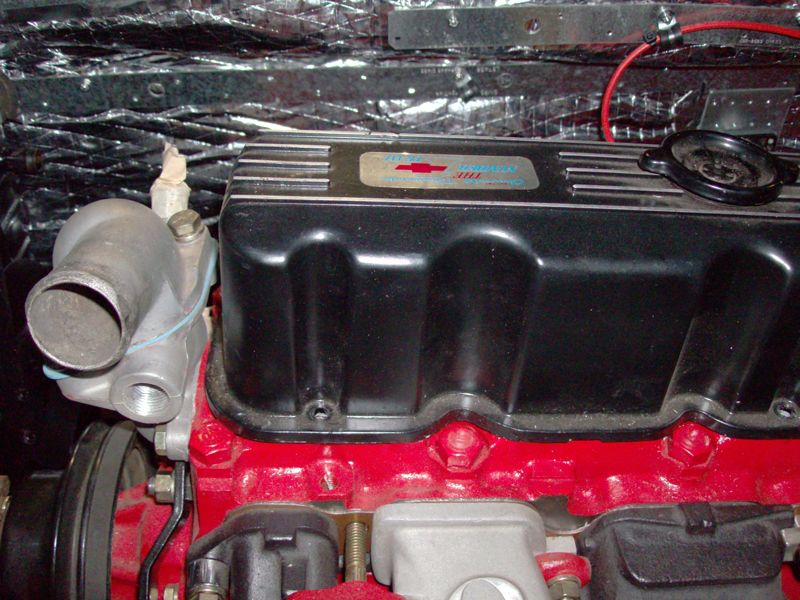

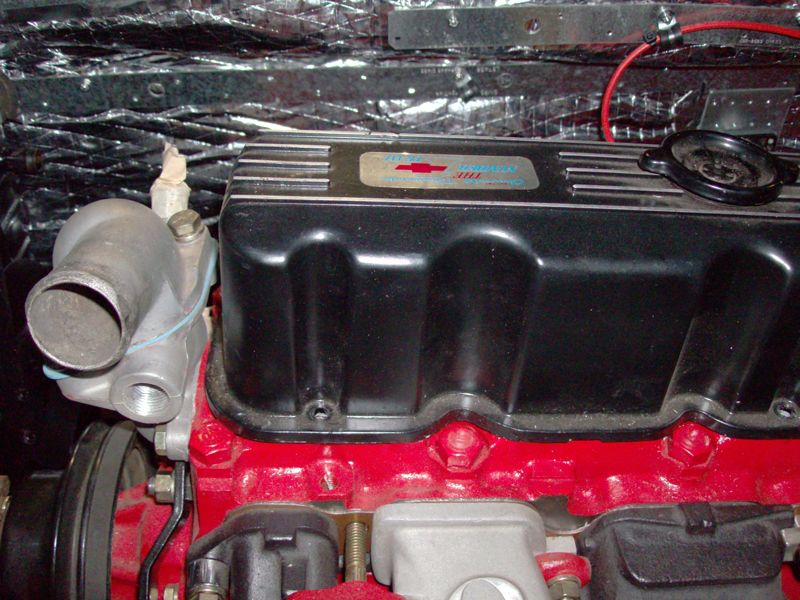

If you look where the yellow arrow is on the old engine you will see where the old gauge thermostat sensor tapped into the engine, but you can see in the lower picture that it doesn't have it. But, while posting these pictures I noticed there is a place I can use in the old thermostat housing, so I'll just swap the new for the old.

Since the van is so old, and the wiring has been kind of chopped, I better just put in my own 10 ohm resistor. Is that something I can easily find in an auto parts store?

As far as the T connector, NAPA should have one.

Thanks for your help.

Since the van is so old, and the wiring has been kind of chopped, I better just put in my own 10 ohm resistor. Is that something I can easily find in an auto parts store?

As far as the T connector, NAPA should have one.

Thanks for your help.

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°134

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Even LOWES probably has the 2" long brass pipe nipple and a T to screw on it to put 2 senders on it, its all 1/8" pipe thread,,,,(they are probably next to the clips),,,,,,,you can use an upper thermostat housing and a lower one IF they have provisions for senders,,,,,,,,I would say the resistor could be near the bulb behind the dash,,,,,out of harms way but a 10 ohm resistor, rated at least 6.25 watts, needs to be in that #1 line.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°135

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Well I went to mount my overflow tank tonight and realized that the thermostat housing I put the temperature sensor into used to hold a tube that cut over to the overflow tank so air wouldn't get trapped in the top of the housing. But I dug around online and found / bought this off of eBay. I think this will more then cover my thermostat needs.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°136

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I'm ready to put the Distributor back but have turned the engine since it's it been pulled. Right now I can spin the engine with the starter, but it's going to be pretty tough to get it to Top Dead Center on the compression stroke.

Any ideas on how to slowly turn that crank to line-up cylinder one on the right stroke?

Any suggestions on how far before or after on the Harmonic Balancer I should set the mark when I set the cap and rotor to cylinder one, or should I set the Balancer to 0 and turn the Distributor so many degrees forward or behind?

Any ideas on how to slowly turn that crank to line-up cylinder one on the right stroke?

Any suggestions on how far before or after on the Harmonic Balancer I should set the mark when I set the cap and rotor to cylinder one, or should I set the Balancer to 0 and turn the Distributor so many degrees forward or behind?

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°137

Re: All Systems STOPPED...

Re: All Systems STOPPED...

If you have the spark plugs out, the engine is easier to turn or if you can get to the ring gear on an automatic you can clamp vicegrips around it to turn the engine. And the mark needs to be somewhat near TDC to start,,,,,HOWEVER,,,,,,,there are 2 TDC's ,,,,#1 and #6,,,,,kinda like AM and PM,,,,,you want the #1 TDC, but sometimes its hard to find it if the lifters are not pumped up or the valves are not correctly adjusted,,,,,so just line the mark up to TDC,,,,,,,slap the distributer in,,,,,wherever the rotor is pointing to is #1 wire,,,,,do the 5 3 6 2 4 wires in the cap,,,,,,see if it starts or trys to,,,move the dist a little in each direction if it shows some interest in starting,,,,,,If it wont fire,,,,,,pull out #6 spark plug wire from the cap,,,,,put #1 in there and then the 5 3 6 2 4 in clockwise order,,,,,see if it starts now.....

EconoCarl- Number of posts : 1109

Location : Beaumont, TX

Registration date : 2008-05-19

- Post n°138

Re: All Systems STOPPED...

Re: All Systems STOPPED...

You could pull #1 spark plug out (leave the others in), put your finger over the spark plug hole, then "bump" the starter until it stops pushing your finger. That will be near #1 TDC. Turn the crank until the pulley shows TDC, then you're there! Good luck with it.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°139

Re: All Systems STOPPED...

Re: All Systems STOPPED...

How much torque to put on the intake and exhaust manifolds. I'm running an Offenhauser intake, and cast iron exhaust and don't know the steps to get it torqued without it cracking?

Do I torque it to 20 or 25 lbs, get the the engine hot, then torque it to 30 or 35 while its hot?

Do I torque it to 20 or 25 lbs, get the the engine hot, then torque it to 30 or 35 while its hot?

whopman- Number of posts : 387

Location : Columbus, Ga

Registration date : 2010-04-01

- Post n°140

Re: All Systems STOPPED...

Re: All Systems STOPPED...

the shop manual shows intake and exhaust at 20 ft pounds for an L6.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°141

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I thought there was a process of torquing a little, heating up the engine, then doing the full torque. The idea was to keep from cracking a manifold, and mine being aluminum I was just wanting to be sure I do it right.

Thanks Whopman, you are the second person to tell me that so I feel pretty good about it now.

Thanks Whopman, you are the second person to tell me that so I feel pretty good about it now.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°142

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I checked the outside manifold bolts and found them under torque, I was able to get to them easy, but how do you get to the center bolts? I tried an elbow, then a wobble, but still don't have enough room.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°143

Re: All Systems STOPPED...

Re: All Systems STOPPED...

I guess I can end this thread now, yesterday the engine came to life again.

https://s829.photobucket.com/albums/zz213/gVanSource/zzz%20-%20My%2068/

If it wants a password it's: unlock

https://s829.photobucket.com/albums/zz213/gVanSource/zzz%20-%20My%2068/

If it wants a password it's: unlock

RodStRace- Number of posts : 3046

Location : Chino Valley

Registration date : 2010-01-21

- Post n°144

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Timing is retarded a bit, and the carb needs adjustment, but it sure does run!

No password needed for me.

No password needed for me.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°145

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Timing will get set today, plus a couple of vacuum lines.

I show the timing to be 10 degrees before BDC for an HEI 250. I need to disconnect the vacuum to the distributor advance while I set the timing right?

Also, will cylinder bore, head upgrades, or cam change, effect the timing? Or should I stick to the stock 10 degrees?

Once the engine heats and cools down do I need to re-torque anything?

I show the timing to be 10 degrees before BDC for an HEI 250. I need to disconnect the vacuum to the distributor advance while I set the timing right?

Also, will cylinder bore, head upgrades, or cam change, effect the timing? Or should I stick to the stock 10 degrees?

Once the engine heats and cools down do I need to re-torque anything?

RodStRace- Number of posts : 3046

Location : Chino Valley

Registration date : 2010-01-21

- Post n°146

Re: All Systems STOPPED...

Re: All Systems STOPPED...

It's always a good idea to go over the bolts and nuts again, just to make sure.

For the timing, 10 should be fine.

For the timing, 10 should be fine.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°147

Re: All Systems STOPPED...

Re: All Systems STOPPED...

The van warms up to 190 with me creeping the choke off a little bit at a time, but I can't open the choke all the way or it dies. It's a four-barrel 600 CFM Edelbrock.

The Edelbrock site says to check the vacuum lines, but they all look good.

So, since I don't know anything about adjusting carbs, do I need adjust for more gas to compensate for the extra air when the choke is open all the way?

The Edelbrock site says to check the vacuum lines, but they all look good.

So, since I don't know anything about adjusting carbs, do I need adjust for more gas to compensate for the extra air when the choke is open all the way?

donivan65- Governor

- Number of posts : 12220

Location : San Diego, California

Registration date : 2008-05-12

- Post n°148

Re: All Systems STOPPED...

Re: All Systems STOPPED...

You need to adjust the mixture to the RPM. There are 2 mixture screws on the carb for this,,,,,,HOWEVER,,,,,,,sometimes these screws are air screws,,,,,,but the procedure is the same,,,,,,turn them out 1 1/2 turns and watch the RPMS,,,,,,,slowly turn them in until the RPM drops,,,,,,then slowly turn them out until you get the highest RPM out of them,,,,,,if the idle is too high, lower it and start the procedure all over again until you get the highest RPM that the mixture screws will allow. I would spray carb cleaner in and on the carb to see if that lets you open the choke without it dying for a test first.........

jrinaman- Number of posts : 890

Location : zelienople,pa.

Age : 59

Registration date : 2011-03-10

- Post n°149

Re: All Systems STOPPED...

Re: All Systems STOPPED...

yes, more gas, so bigger jets and metering rods, easy swap on an edelbrock. but before you do that, double check and triple check for vacuum leaks. carb gasket, intake gasket, open port you missed. you can check gaskets or intake by holding a propane torch near area in question with engine running, if there is a leak, it will draw in the propane and engine will pick up rpm's. dont light the torch, you just want the gas. do you have a heated intake? not that it gets all that cold in texas in august but the intake needs to be hot enough to keep fuel atomized. 600 cfm on an aluminum intake hanging off the side of a 6 banger might not stay warm enough, evan if its 120 in your van and water is 190, your air/fuel mixture can be much cooler. langdons stovebolt has an article on this and could be your problem.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

- Post n°150

Re: All Systems STOPPED...

Re: All Systems STOPPED...

Probably a stupid question, but what my target RPM for the engine idle?

|

|

|