Its good to have some rules,,,,,and its good to have some advice,,,,some people understand the rules better than others, based on their skill, experience and abilities. So keep it all coming,,,,,it keeps you thinking,,,,like why did he do or say that. So lets go back to my advice,,,I see a new type of brake bleeder for sale,,,,,it connects to the brake bleeder and PUSHES fluid back up to the master cylinder,,and you got your vacuum pumps that PULLS the fluid out of the master cylinder through the bleed screws as well as a pressure type. Those are good if you do a lot of brake work. And then there is the old faithfull, pump the brake pedal. And that leads to my advice about disconnecting each line. We did a 4 wheel disk conversion on a Chevelle and could not get the air out of the rears,,,,,by pumping the pedal. And all I could figure was that the fronts were building up good pressure, which stops the movement of the master cylinder piston and that keeps the pressure from building up in the rear section of the master cylinder which does not allow the air to be pushed out the bleeder. And basically the front section of the master cylinder vapor locks the rear. And I know taking those lines off cause air to enter again, but my point is to do each one separate,,,,,see if you get equal brake pedal height,,,,,then you know that the master cylinder is good and each system is working. Right now there are TOO MANY VARIABLES, I like to isolate each piece of equipment and check it out and move on to the next one. (I am not much of a rule or book reading guy),,,,,But its all good,,,,,,you are doing a good job M1,,,,I like seeing your take on repairs and ideas,,,,,and you sure are not shy about going outside THE BOX to try new ideas!!!!!!

we have a Corvette master and a residual valve. What do you think???

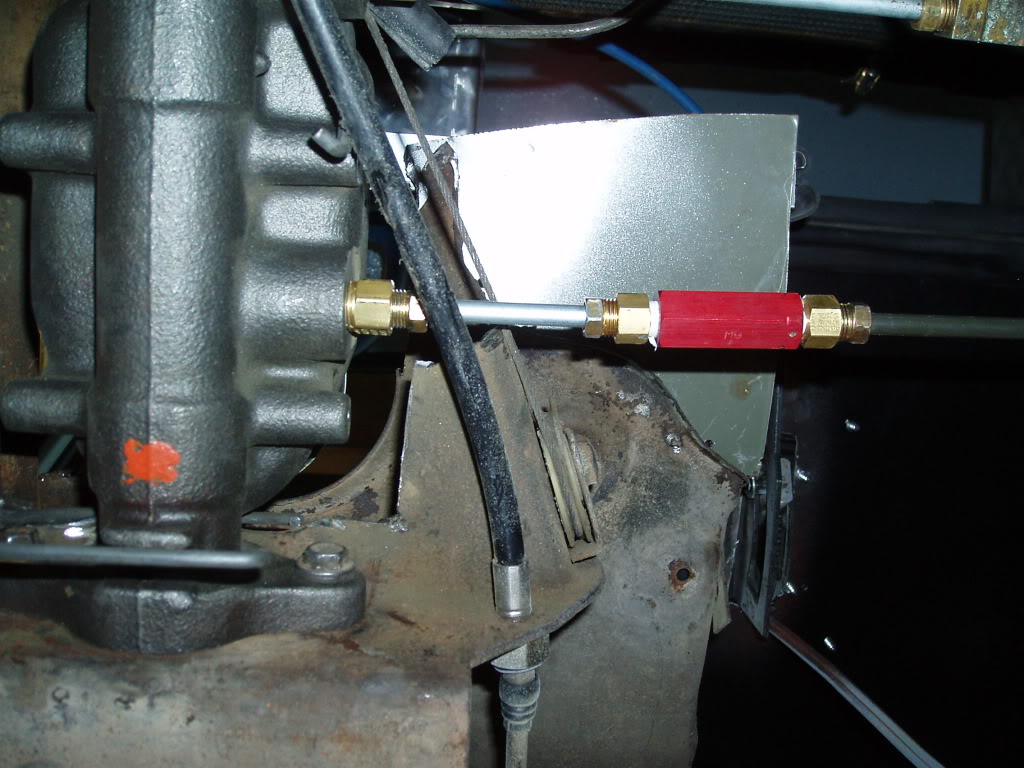

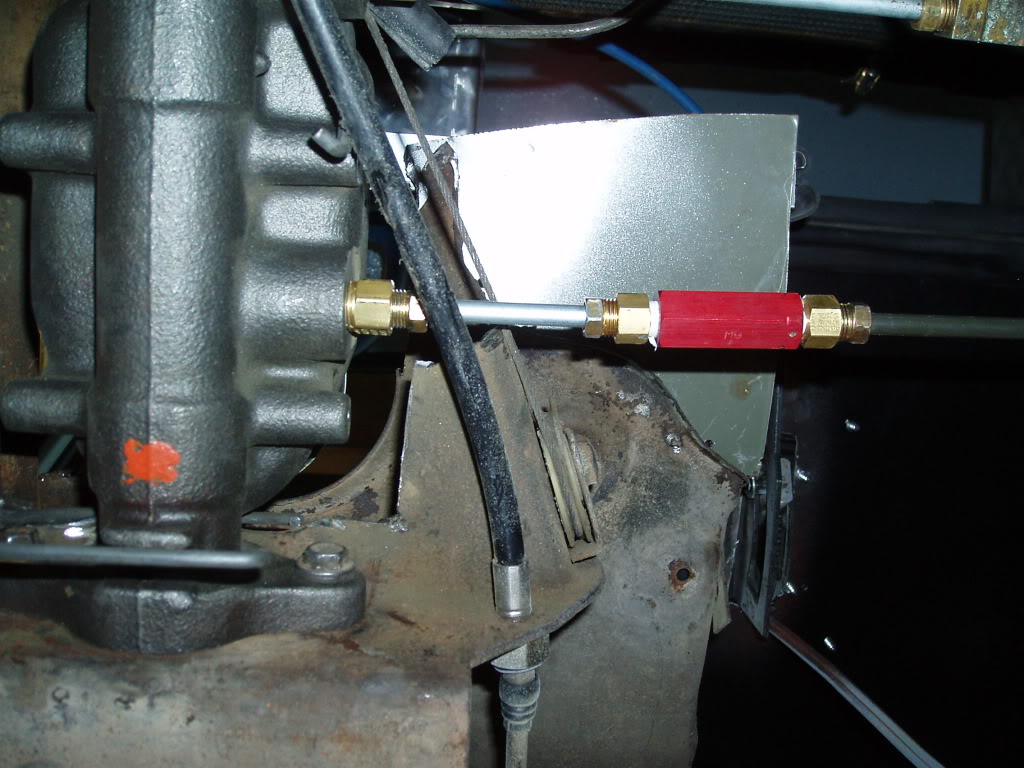

we have a Corvette master and a residual valve. What do you think??? New connection to rear

New connection to rear

we have a Corvette master and a residual valve. What do you think???

we have a Corvette master and a residual valve. What do you think??? New connection to rear

New connection to rear