Pictures can be deceiving, but not to worry...even at full right there's four inches between the tie rod and drag link, 2 under the steering arm, and a 1/4 over the axle as the ball joint passes by, and these are fixed relationships, the rise of the pitman arm to 4 o'clock in the process of a right turn also helping out with the latter. When you think about it, the rise of the working end of the pitman arm in either direction helps maintain the downward angle of the drag link during the left and right steering motions, and thereby reduces the chance of bumpsteer even at the extremes. Which brings us to the pitman arm for one last post before I get back to sandblasting doors and fixing dents. It was good to hear that the pitman is close to vertical, which makes sense in the diagram below, and saves me a misguided trial of putting both ends of the drag link at 90 degrees to the pitman and steering arms. It also explains why the working end of the steering arm is slightly ahead of the axle centerline in the stock arrangement...at least as I see it...

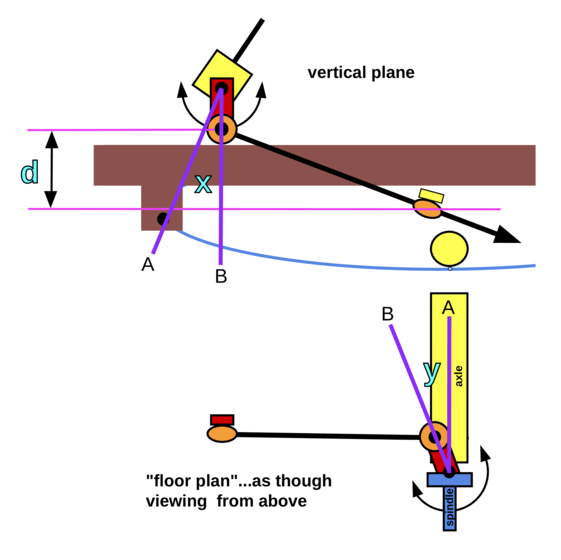

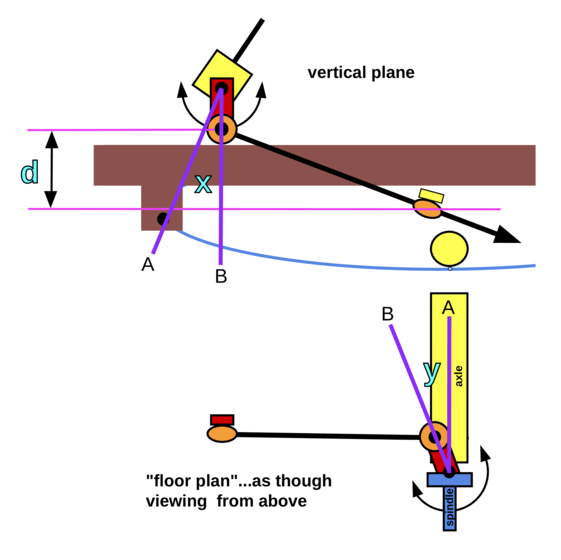

So here goes: With the pitman arm in the vertical position, it's in an "inefficient" relationship with the drag link...not at 90 degrees, as it would be if the arm was aligned with line A; it's shy by the amount of movement in angle X. But in the vertical position, the top line for the "d" measurement is thereby established, and any right or left motion remains symmetrical in terms of motion imparted to the drag link. As well, had the neutral position been on line A, the ball joint and drag link would swing lower in moving to the vertical position, decreasing "d" and making bumpsteer more likely in a right hand turn.

Then there's the matter of a similar situation at the drag link's connection to the steering arm. The angle Y on the diagram reflects that the steering arm is not on the centerline of the axle; it is 1 1/2 inches in front as measured from the ball joint center, and thereby not in a 90 degree relationship with the drag link. This, too, would normally be an inefficient relationship in terms of imparting movement from the drag link to the steering arm, but I would bet that it matches that of angle X at the pitman arm. What happens? Starting from its 6 o'clock position in a right hand turn, the pitman imparts motion to the drag link in shy-of-90 fashion, becoming even less efficient in its motion, while at the same time the steering arm approaches 90, becoming more efficient. One end of the drag link is giving up the ghost, while the other end is regaining it. The exact opposite occurs in left hand turns. In such fashion there is likely to be a much more balanced and sustained feel to steering wheel inputs in going from lock to lock. With a 90 degree relationship at both ends of the drag link, steering would be "gangbusters" initially, quickly petering out and requiring faster wheel input to keep up with both connections going inefficient at the same time. I'm happy to have avoided another experiment in steering arm sculpture.

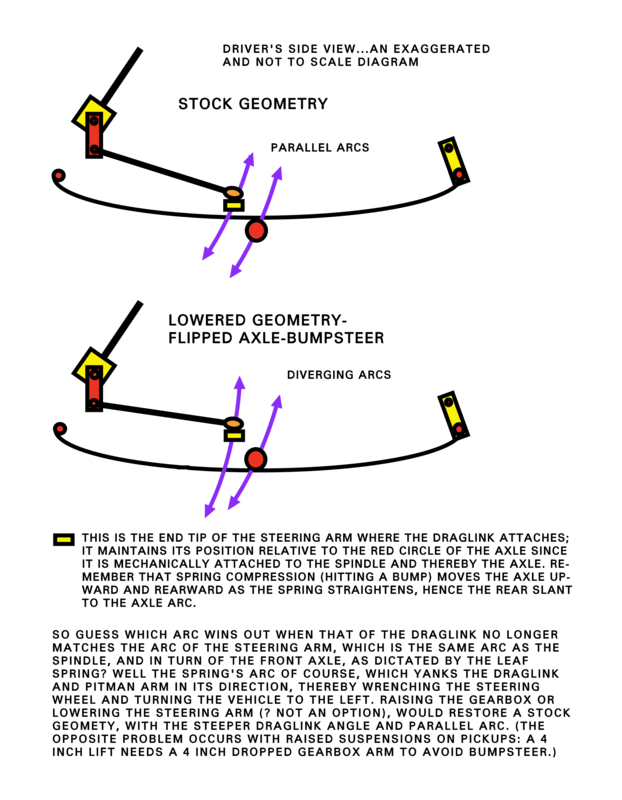

OK...that's all I can say. I'll stick to my assertion that in altering the relative vertical position of the steering arm to the pitman arm ball joint, by raising or lowering one of our vans with side-steer geometry, the stock "d" has to be reestablished, as well as the drag link's angle of descent, because these two things put the drag link and steering arm in the best location for following the upward and rearward motion of the axle during spring compression. There's no bumpsteer if everything is in the right place. In my case I raised the steering gear box to get "d" back to spec and may go another inch since my van is an unloaded shell on wheels. I'll keep looking at the 29 inch drag link, as my 4x4 conversion resulted in a one inch rearward axle location to center the tires in the wheel openings, but as in my very first diagram, its a matter of parallel movements, and there is a sweet spot where all goes well. It's very close, and I'm almost satisfied...I hope it's just a few more tweaks. Mostly I need to crawl under a stock van and measure the setup, taking a good look at the pitman arm...it all makes sense to me, but my mother always told me I never had any.

For now, it's back to sandblasting the doors and finishing the body work. I've got to get this thing painted and start putting it back together. The moral to the story should be this: unless you are crazy, have decent welding and fabrication skills, and enjoy spending way too much time working on an old van...you should leave well enough alone and instead have fun driving it. Keep fiddling, too! V. Olins

Last edited by V. Olins on Mon May 15, 2023 5:21 pm; edited 2 times in total (Reason for editing : typos and clarification)