http://vintage-vans.smugmug.com/Dodge-a100/66E100PUs-New-Toy/45028705_dkmHTZ#!i=3618796315&k=f2H2ftM

I will try to keep the thread updated as I go. This is a little on the radical side, so it should be fun!

Jim

A-100 Project

A-100 Project Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Project

Dodge `66 A-100 Gas Tank

Dodge `66 A-100 Gas Tank Re: A-100 Project

Re: A-100 Project Re: A-100 Project

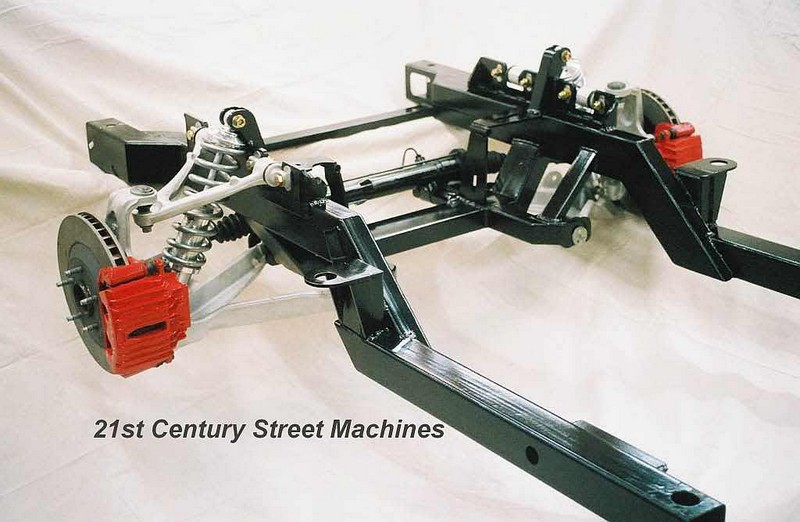

Re: A-100 ProjectWadehawkins wrote:Can you tell me about the C4 front end? I'm doing a resto mod. Want it to ride like new and look like it just rolled off the line. Also a March pulley system would really set that motor off! I put one on my 450hp 340 and its badass!

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

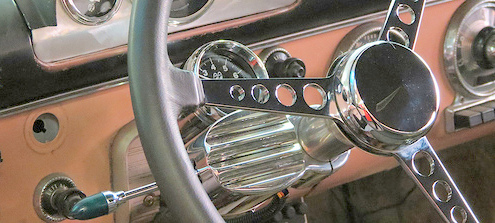

Re: A-100 ProjectBig W wrote:Sliding rag top.....Kool idea. I like that gauge cluster also. Are you keeping the steering wheel? cus that looks great with the gauges.

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Projectbenwah wrote:As a Dodge guy., And looking at your options Id say Ford. Somewhere I have some 53 Buick or Cad taillights. You got me thinkin.....

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Projectvanny wrote:That under-dash mount is a Great Idea! Nice alternative that'll look like it's meant to be there!

Re: A-100 Project

Re: A-100 Project Re: A-100 Project

Re: A-100 Project