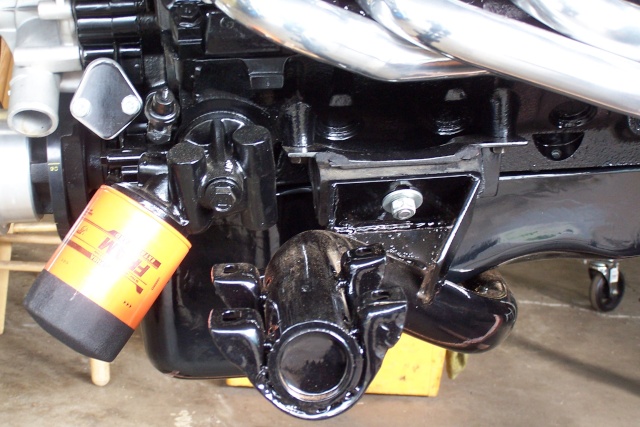

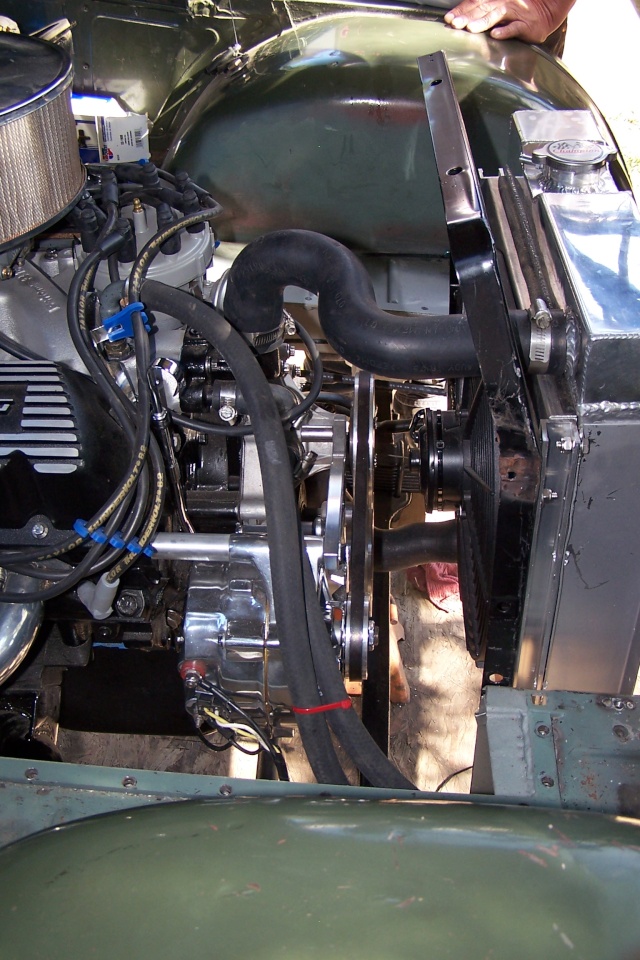

The pics of the cross members were my pictures,,,, and the short cross over bar is the big six one, the longer of the two the small six. Personally, I found the stock 240 towers too high and not the exact same angle as the small block V8's, and also found the 351W mounts to be larger than the 302's but still bolt in, so I make the engine pads on my cross members to fit the larger mounts. (pictures of the mounts a also) Also, found by using two different yr mounts with lefts and rights, I can then get the studs in line with each other, which makes the towers sit like each other and better. The engine cylinder pattern puts one mounting location for the mounts in a different position on the engine, when you measure from bell housing to engine mount holes on the block itself, same strong points of the block itself. I have detailed pictures of the differences if anyone would like them??? Also, a showing a digital measuring angle finder showing the correct mount angles.

Also, have been using for years what I think is an easier way to pull engines in the pickups. Very easy to make one out of scraps. It assembles inside the truck in pcs, made out of pipe and angle iron. The angle iron pads can slide back and forth on the floor board for fine tuning back and forth, its easy. The support pcs are nothing more than a two short vertical pc of water pipe, (one for each side of course,, LOL) with a short (6") pc of larger diameter pipe welded on top at a right angle to the floor sliders. You simply slide a cut pc of pipe inside each of the two (6") pcs on each of the two vertical supports. I welded nuts into mine to put a bolt into to tighten them down,, (NEVER USE THEM) A Welded tab in the center and on the bottom (LOL),,,, of the cross pipe. You don't have to worry about scratching anything with a cherry picker or having to re install the right front door and realigning it. ( I also used it to find and hold the perfect front position of the engine when making the new V8 towers).

For the sixes in and out, its too easy on a pc of plywood with the engine on its side, slide it out or in under the truck, lift it up or down. Easy up and in, hold in position Once it gets past the side of the truck its home free. Way too easy, way too inexpensive,,, works like a charm. Again, detailed pictures for those who would like them??? On either, I simply use the cherry picker to lift the front of the truck in the air, too easy,,, pics of that one also, on a 351W I put in a 62 five wndw with an AOD.

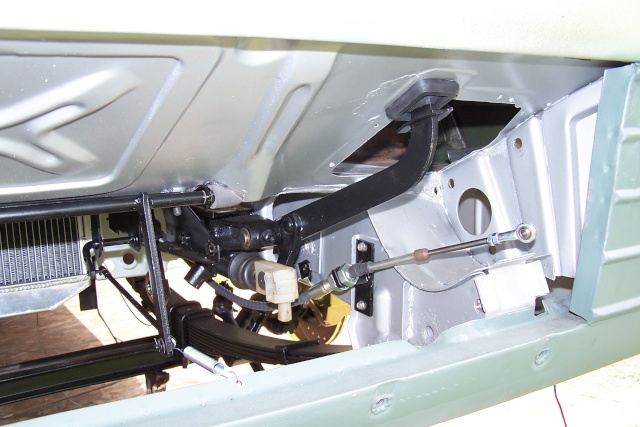

I also, put together for the people who want to make their own cross cross members, detailed pictures of how I do it.

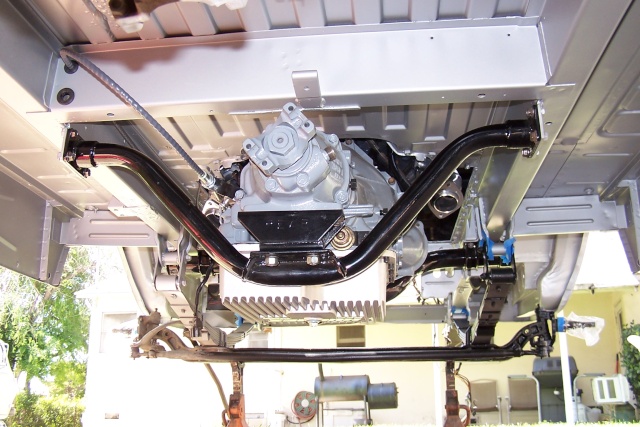

TO ME, its ALL ABOUT CRANK SHAFT CENTER LINE to measure your drive shaft angles, center of the front of the truck and the trans end of the truck, it all runs off of the center line. Using it, you cant miss getting any engine to sit EXACTLY where it needs to be.

MOST all intakes have an angle built into them to set the floats in the carbs from flooding , if you look at either of our six cylinders, you will see an angle in them so the carb will sit correctly, same with V8 intakes, its built in on purpose to allow the engine to be mounted at an angle. So when I set them up in ours, I copy the factory drive line angle using the center line again to copy it on the new tower height. When the center line of the crank is extended out the tail stock of the tranny and that drive shaft angle is correct, it AUTOMATICALLY gives you the front engine height when you pivot off of the transmission mount. If using my tranny cross member, it is still the same because you have set the trans height as well as the drive line angle, which only leaves ONE position for the front of the motor. if you set that angle correctly, the front height can only be in one point. I feel using it to set the intake angle AVOIDS any problems with how accurately I set the level of the truck floor, even if it is setting on the frame and NOT on the axles as the springs then would be involved in the settings. This way, it is EXACTLY as the factory set ours up as.

If anyone would like pics in detail of how to set up your own cross member, I can send them no problem to your mail address, would love to post them here, but still not working for me,,,,,sorry.....

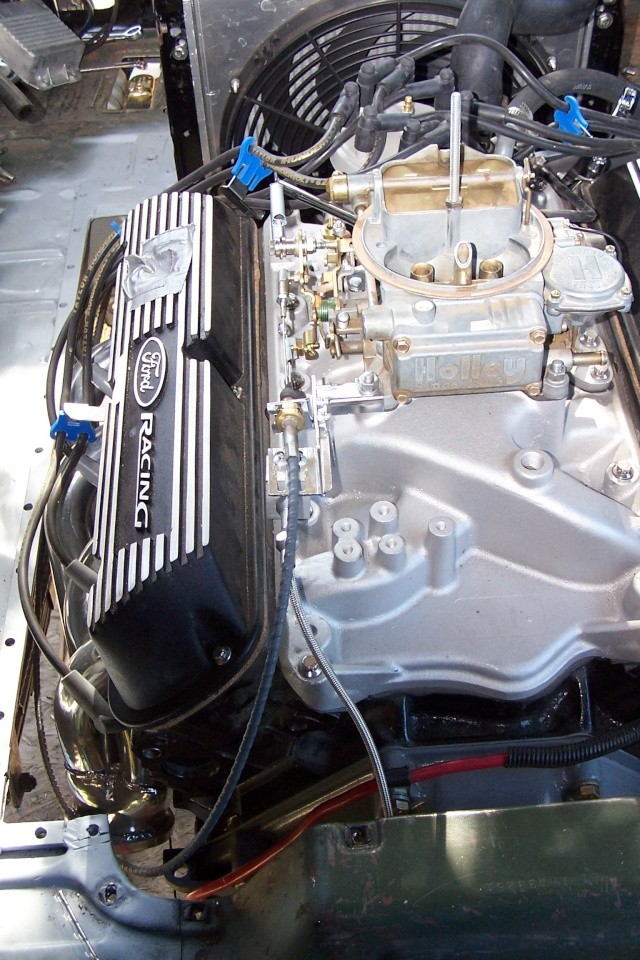

I forgot how or where, but there were some pics posted for me that show my latest 351W setup using a C6 and the short tail stock I put on it...

vic

V8 Engine Swap, by Hellfish

V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish  Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish  Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish  Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish

Re: V8 Engine Swap, by Hellfish