by PizzaChop Sun Apr 18, 2021 6:13 am

by PizzaChop Sun Apr 18, 2021 6:13 am

NOTE: This entire episode could have been avoided had I performed a critical "check" which having failed to do, resulted in another "painful lesson" which I now share with you.

The experienced will have a good laugh, but those who've yet to do this....take heed!

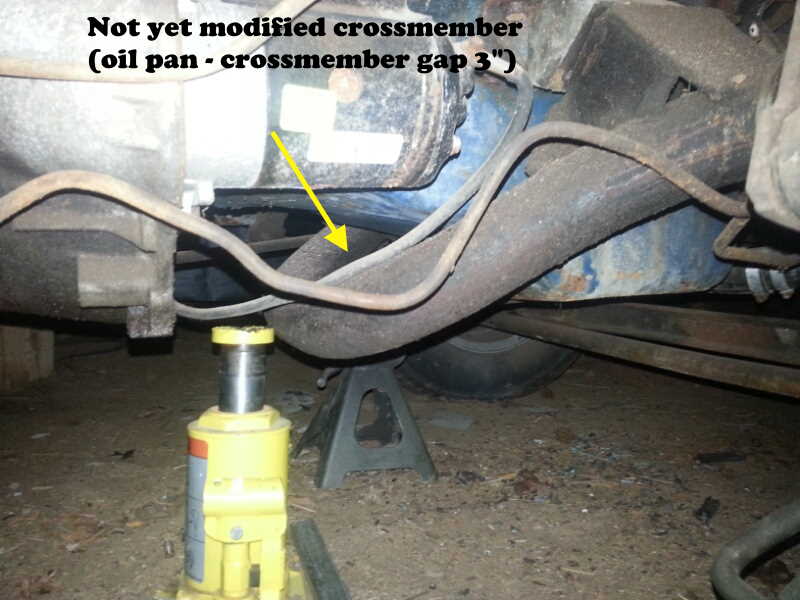

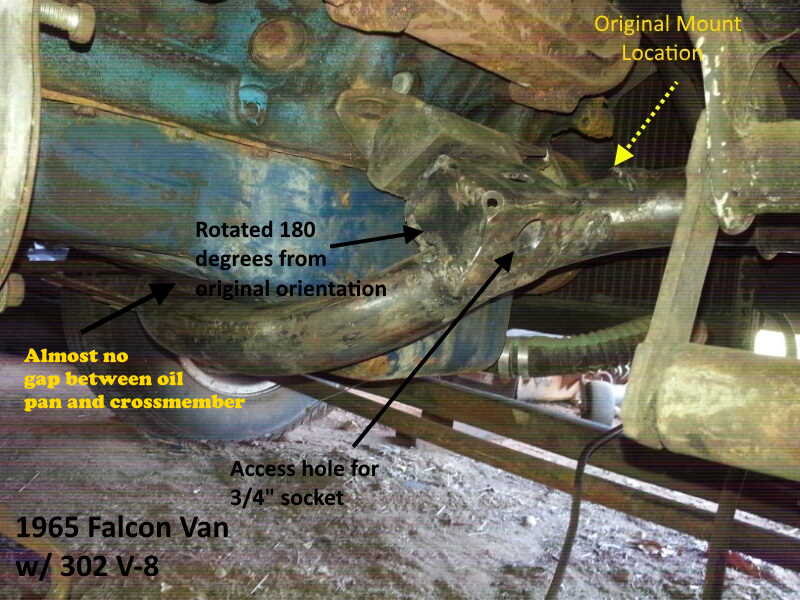

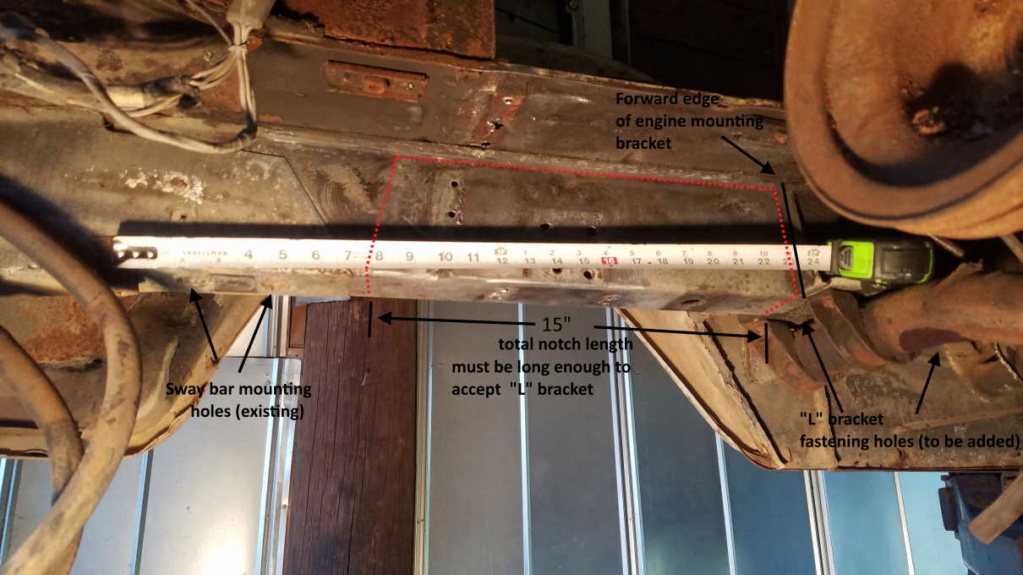

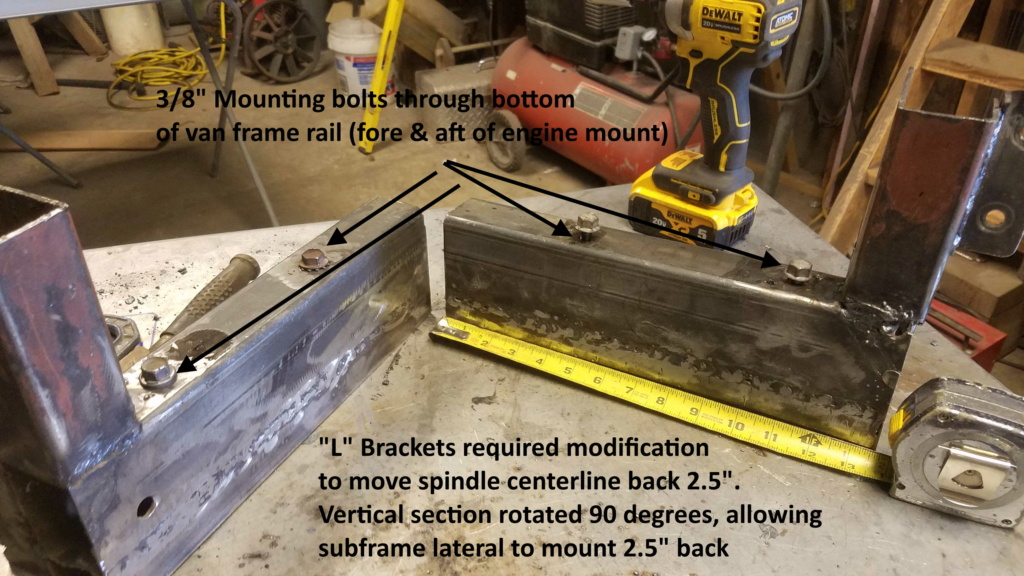

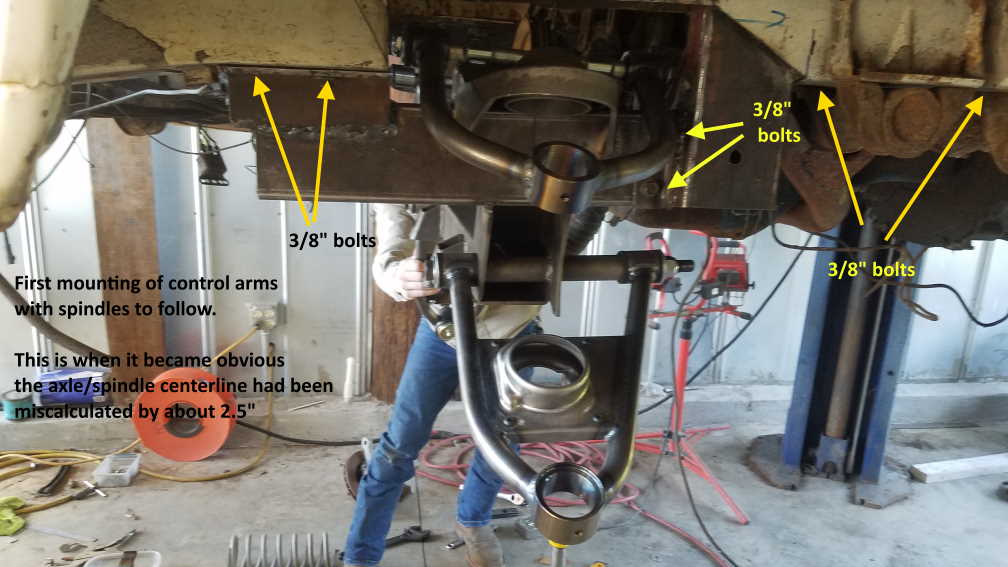

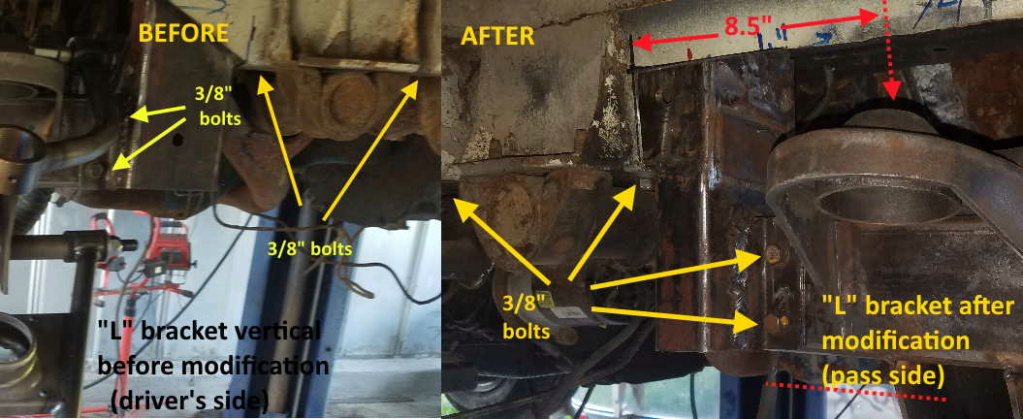

Now that I had successfully moved the entire subframe/crossmember rearward 2.5" by modifying "L" brackets in rear, extending notch in van frame rail almost to engine mount bracket, and lining up forward mounting bolt on front angle bracket with rear sway bar hole.....it should be smooth sailing.

Except it wasn't.....

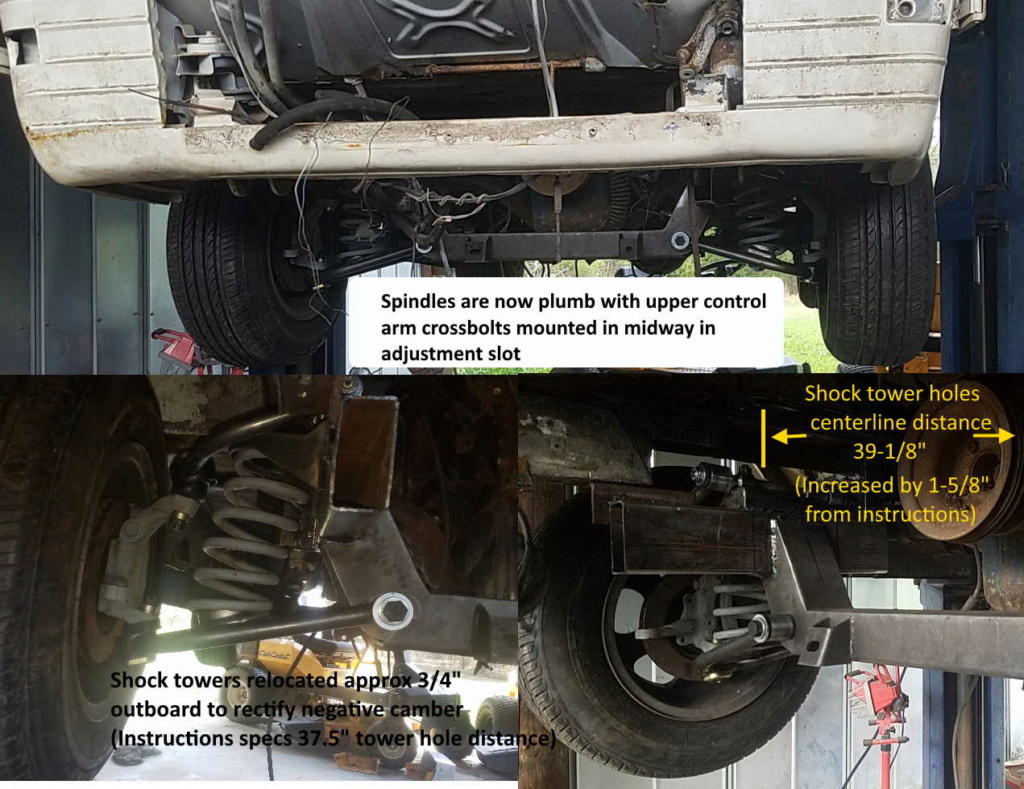

Once control arms/spindles/wheels were installed and van lowered to ride height, it was immediately apparent that I had a significant negative camber situation which could not be corrected with cross shaft bolt adjustment.

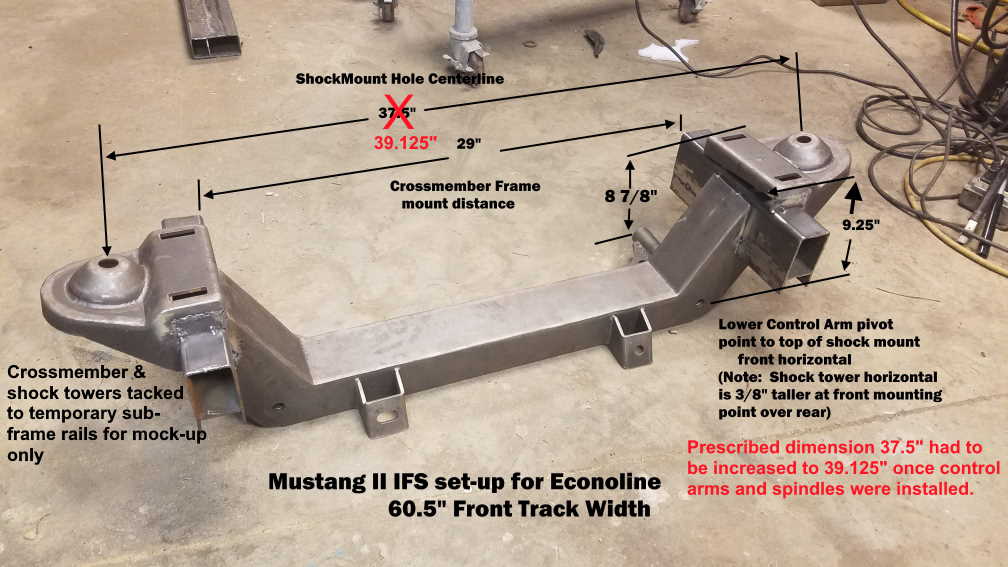

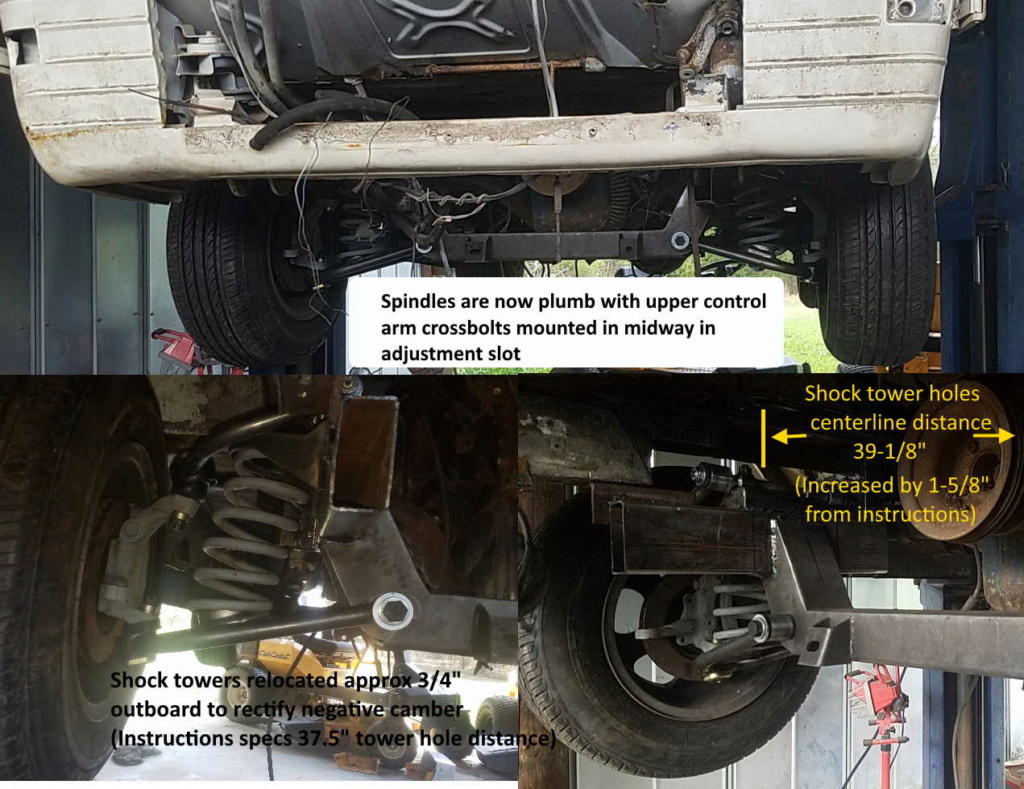

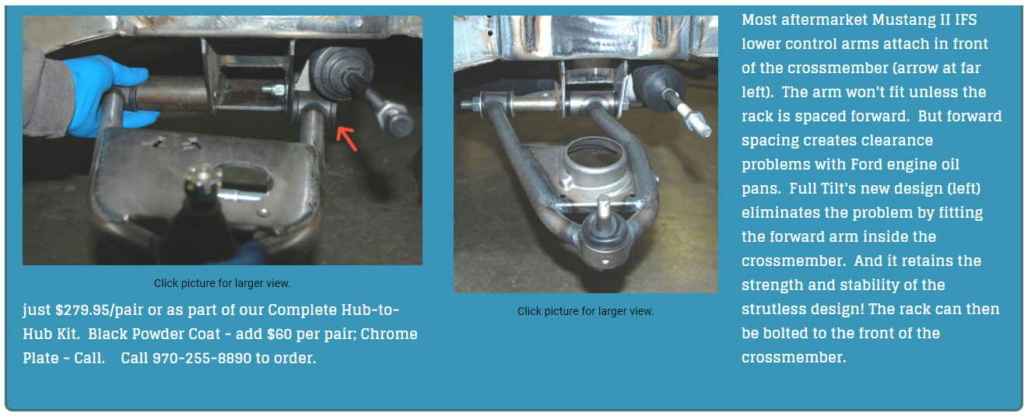

When initially welding towers and crossmember to rails, I had followed the Heidt's guide for my generic ebay crossmember/shock towers which specified 37.5" span between shock tower holes (29-30" crossmember, 60" track). Puzzled, I called Clay at Full Tilt Streetrods (control arm source) and described my dilemma.

He explained (and I later noted it was included in their instructions) that the shock tower mounting width MUST produce plumb spindles with cross shaft bolts at mid slot, regardless of any other prescribed distance between towers.

The answer was so simple....just cut off and re-locate the shock towers! (after I had already permanently welded them in place). Of course we know nothing is permanent with a plasma cutter and/or cut off wheel, so I once again (lost count) removed wheels/spindles/control arms and then removed subframe assembly from van. (The bolt-on mounting method was really paying off HUGE dividends at this point!)

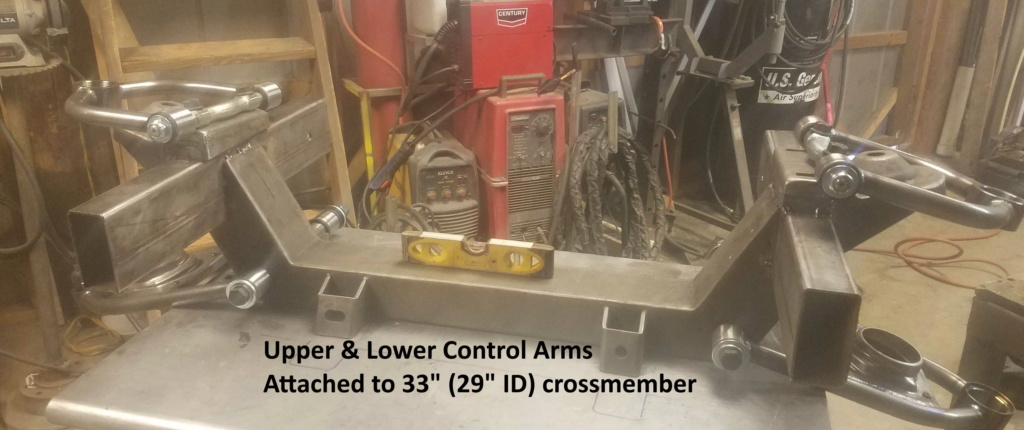

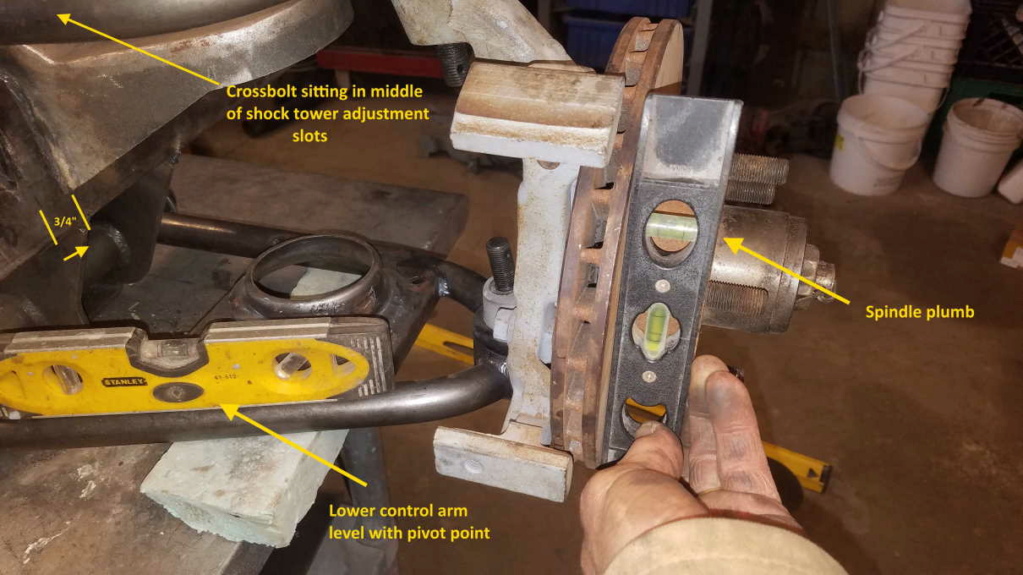

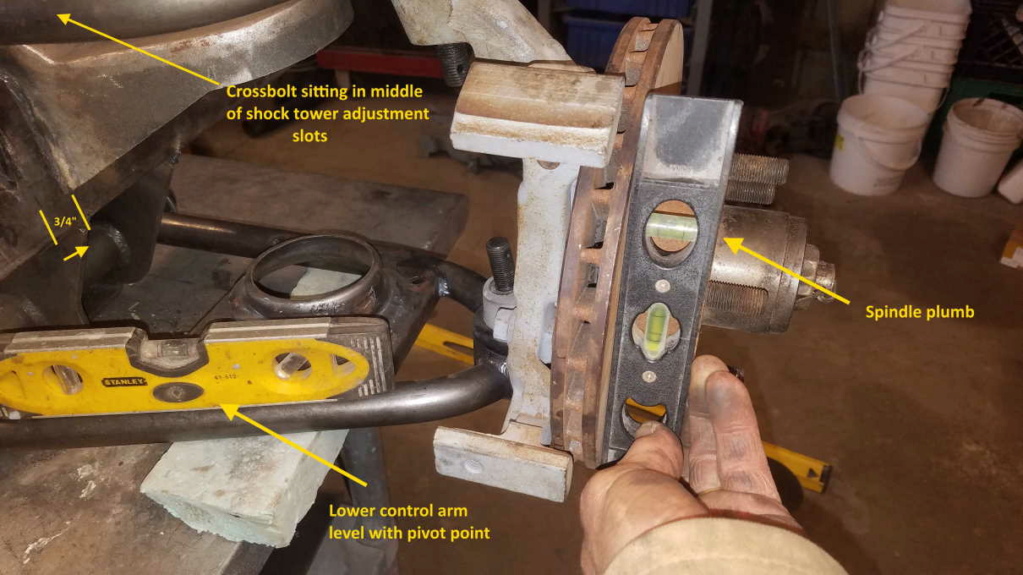

After cutting off one shock tower, I re-assembled the entire IFS on a bench, leveled control arms, and moved the tower out until the spindle was plumb (both crossmember & arms level).

It required about 3/4" outward to produce plumb spindle face at with cross shaft bolts at center slot so after tacking one side (making sure it was level side to side and kept the rearward slope of 3/8" front/back), I cut off and relocated the other side to match. (I filled in gap created from outward re-location with 5/16" steel)

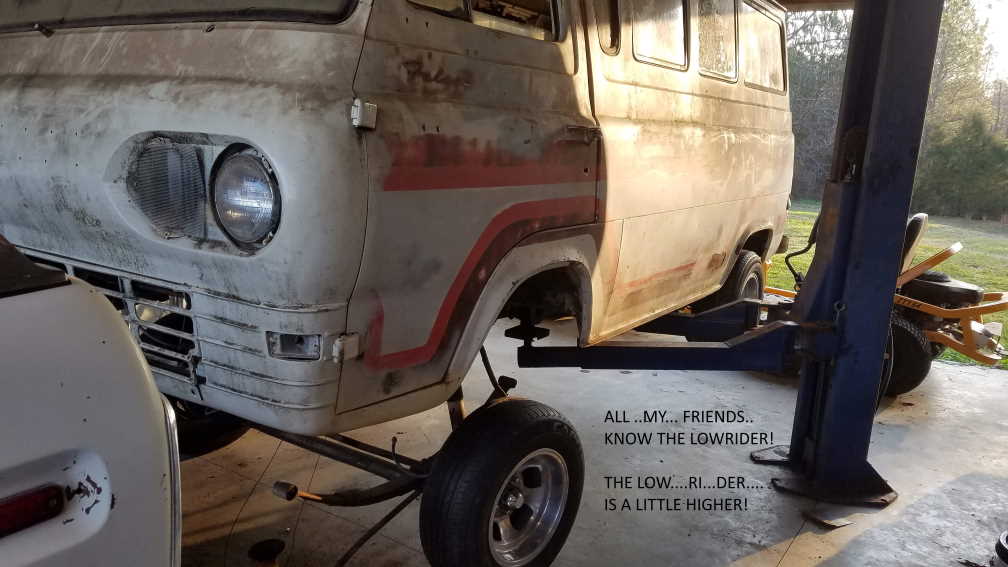

Now satisfied that I finally had the IFS the way it needed to be, I stripped it of control arms, bolted it back up, and installed arms/spindles. Lowered it down and I had zero camber with cross shaft bolts at mid-slots in towers.

This is what it looked like before shock towers were re-located outward

This is after

Last edited by PizzaChop on Tue Apr 20, 2021 11:58 am; edited 1 time in total (Reason for editing : Shock tower slope should be 3/8",not 3/4")