by Seth G Sat Dec 28, 2019 6:20 pm

by Seth G Sat Dec 28, 2019 6:20 pm

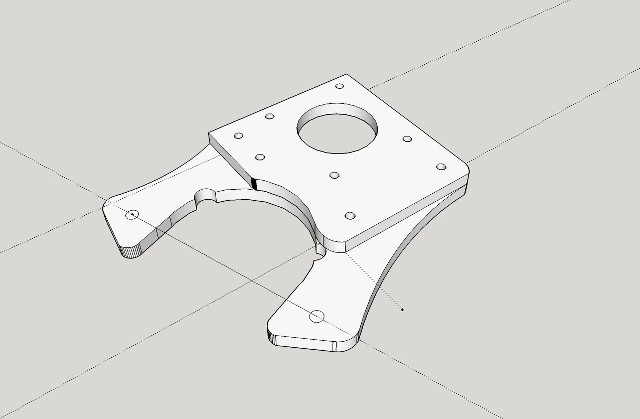

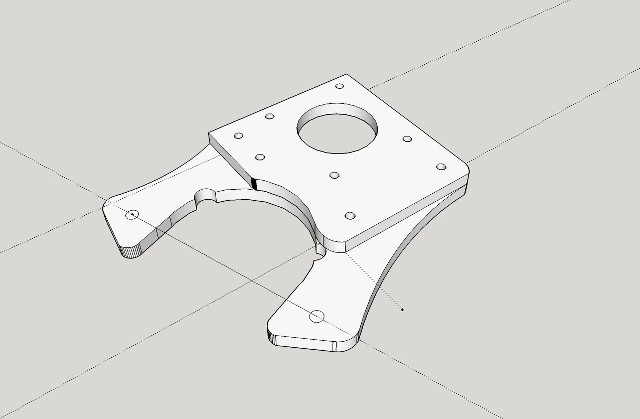

I have cad files for the brackets and spacer. It was designed for GM metric calipers and can be altered for any rotor you want by changing the distance from the hub center to the caliper mount holes based on rotor diameter and the thickness of the spacer for the depth of the "hat" of the rotor. There is a Dodge Dakota rotor that is ideal. I used a thinner one and had slight rim interference from the oem GM caliper, but would have no interference problems with the sway bar links like the D and D kit. I believe the Dakota rotor will have no rim issues

and no sway bar link issues. I've been meaning check it out but my van is the only one I have and it involves alot of taking things apart and the van would be out of service. I also know the ideal studs to use. And they aren't the ones in the d and d kit. I'm not being coy, I just don't remember the specifics off hand, it's been to long. I'll have to refresh my memory of the details and part #'s.

The d and d kit(based upon the studs and rotor in the list) has to have the rotor staked to the hub via knurls and turned on a brake lathe to be trued to be done right imo. One big problem with that imo is that the knurl on those studs is HUGE. It will stretch those holes out way beyond their oem bore. With my setup, similar to Vic's setup, this isn't needed and there is no interference with the sway bar links. The new studs are a proper interference fit of ~1.5-2.5 thou after a clearance is taken out by drill bit from the oem holes. .912" iirc. The new studs are installed, wheel and rotor are torqued to hub, then the wheel is pulled off, the studs marked for their radial position and to their respective holes, popped back out and then the hub is true'd on a brake lathe. The studs are reinstalled and the rotor interfaces on the smooth nub at the bottom of the new studs with a nice fit. No machining of the rotor holes or the hub/rotor combo need if the rotor needs replaced.