Andrew,,, at the risk of being called arrogant I would like to help you with all that I have learned since 1st putting in a V8 in 1966. That with a LOT OF MISTAKES,,, LOL I now also have a collection of re do's of some pretty absurd installs over the years for my museum,,, point being,, done a few and have seen quite a few and so I have learned a lot from others mistakes.

SO,,,,,, as I have plenty of work to do, I dont want to get into any spiffs over stupid stuff...Today with another few on the phone,,,, WOW.....

Also,, its really hard to read the whole post when replying a long one, and so some may think it as rambling but its hard to look at it and keep it on track,, sorry if so,,,, important part is to be detailed in order for people to understand it and at the same time it may save some valuable work time spent on the keyboard,,,, LOL

To avoid confusion as some people dont know,,, and EARLY is considered from 1961 to 1964 and a TON of information there,,,, A LATE is considered from 1965 to 1967 and a GENII considered from 1968 to 1974 as we use some of their parts also for ours.

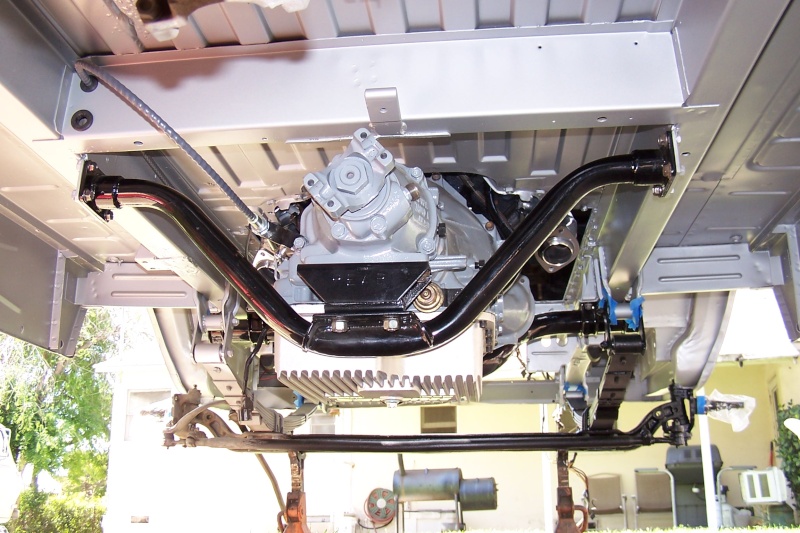

IMO,,, from your pictures.. Whoever did the install was on the right track in using two cross members. The faults being how both of them are built as well as using the wrong tail stock on the transmission. The oil cooler on the right track except for it can ONLY WORK if the truck is moving and even at that with no direct air flow going through it.

ENGINE CROSS MEMBER: LOTS of information here for you and the others but for this subject you have one only inboard frame mount on each side of the truck and not two like the "lates" have.The lates with two one on each side of the truck (one inboard and one outboard) with these two sandwiching the frame and are also about 4" FORWARD of where you present single mount is located.

Its very hard to beat the strength and the mounting of the lates and so I use the lates x member core and cut the towers off of them, making no difference if a 170 or a 240,, doesn't matter.. I built a jig fixture using a plastic mock up engine and transmission and so the engine height, centering and drive shaft angle are already figured out to fabricate new towers in place on that core. Its all figured out already....HOWEVER as your frame mount is rear ward of where of the lates location I use the front hole on your existing mount and bolt it to the rear bolt hole on the new cross member. This places the engine as far forward as you can go without the tie rod on the front axle coming up and hitting the front of the oil pan,, (keep in mind that when the spring collapses the axle also moves rear ward towards the oil pan)... The sides of the frame ARE TAPERED and so when people try to use angle iron for a new frame mount it angles the bottom mounting surface at an angle also,j........(d-h),, so I typically use late model frame mounts that I cut out of scrapped trucks as they have the angle built into them OR I construct new ones in place out of two pieces welded together on the truck to get it correctly. This being what I do on an early by welding a plate from the front of the existing mount forward to the front of the new cross member mounting plate. Then I weld in a bottom piece to that piece to match where the new forward bolt needs to go. Drill a hole in firstly,, bolt it together of where it needs to be with a gap at the intersection of those two pieces for your welding. The picture showing how I used to do it years ago with the extra pieces welded in for strength...(not needed)

What you end up with is,,,,, four bolt mounting points in the correct position in order to use a full strength engine cross member in the correct position and drive line angle...

TRANSMISSION CROSS MEMBER: Using a transmission cross member on an early gives you the advantage of being able to set the bell housing clearance and drive line angle. Yours looks to be fairly stout (?) from what I can see. I make one that swivels and follows what you are doing and at the same time expands or contracts allowing you to also center the transmission. Our trucks with the crank shaft centerline exactly in the center. If I see yours correctly it looks like the car type tail stock hiding in the background.. LOL There being two issues with it. The 1st is that the drive shaft ends up being so short (ours with a short wheel base AND the engine next to us) that drive line vibration becoming an issue and or difficult to get rid of. The TRUCK type tailstock being much shorter which gives you a much longer drive shaft but ALSO the drive shaft is now supported by a ball bearing (still looking for my missing pics)...instead of a weaker bushing that usually ends up leaking also..... The short under mount type tail stock,, having the mount exactly in the same location but a shorter tail stock... I think I posted it but will again///?

TRANSMISSION COOLER: ANY cooler needs something to exchange the heat to some other place. IE: It needs air to go through it in order for it to work. If a vehicle isn't moving there is little to NO air going through it. A fan operated cooler not caring if the truck is moving, sitting still in stop and go traffic or still running while your having brew!! The remote fan cooled unit NOT adding heat to the present radiator load,, IE: The century old comment,,, toasted the engine and also fried the tranny at the same time,,,

RADIATOR: A lot of people trying to use the Mustang as its cheaper (just also getting some emails on that one AGAIN,,,,, even though they admitted having read my info before,, still tried and another one saying it didn't work,,?????????

Our trucks have an oven inside the truck with no way to get the heat out of them and on top of that then we insulate them so we cant feel that heat?????????????????? Doesn't make much sense to me?? IE: The larger the heat exchange surface area there is the better it will get rid of the heat. The late 240 radiator over 4"'s taller in height alone... IE:: more heat exchange area... Personally my favorite is the Chevy (forgive me) cross flow,,,, it cant be beat~~~ I have one waiting for me to use,,,,,,,,,,, also I have and use the 240 and have it bumped up to a four core. I also like the idea of its dimensions in that the Taurus ( found that one for us) is said to have 4200 CFM two speed fan. ( a some day? project is to make a unit to measure CFM correctly and test them all),,,,as it comes with a shroud that already fits the 240 radiator, is inexpensive and pulls the most of any fan I know of?? The two working really well.

DOGHOUSE: The early is 1 3/4" shorter in height than a late, has no hump in the back of it for added bell housing clearance and air circulation. The early with two latches on it and the late with one. As yours is a e pup its much harder to add the hump to the rear of your cab. I am doing one for a customer right now, but no fun. In a van its very easy..

For sure open up the doghouse under the seats,, Not done on the Falcon van, advised to, and admitted a mistake,, I have heard it so many times,, please consider it. I support the seats with them, brace them under neath for strength in an accident. It allow you room for insulation as well as some air movement past the exhaust. Regardless of shorties or stock manifolds. Also,, remember that the early doghouse is shorter in height than the lates,,,, ALSO I plug weld a 5/16th thick by 1" wide piece on where the new box will bolt up to on the floor. After plug welding it in place then I drill the holes, bolt it together and tack weld the 5/16th nuts in place under the truck. Gets rid of the cage nuts that always spin,, This way,,,, the mounting surface is flush with the old floor height and it mounts cleanly.

vic,,,,,,,,,, aggravated over lost pictures,, dratzzz,, over 1,000 easily