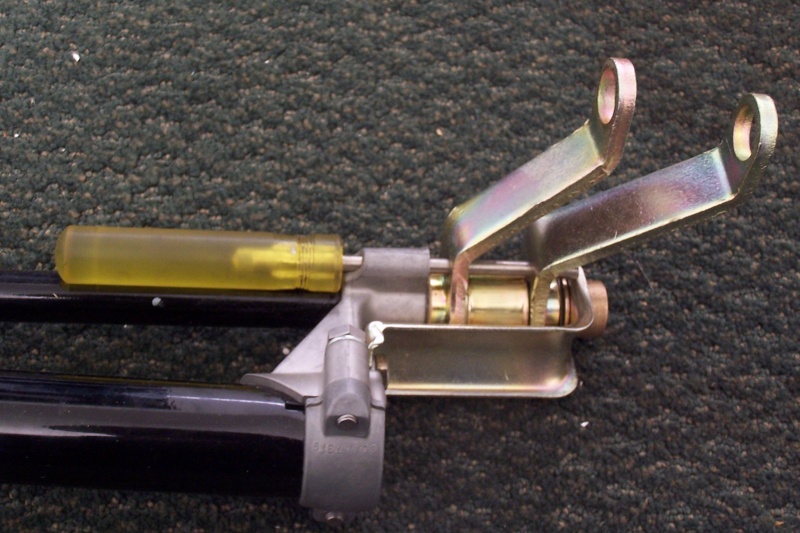

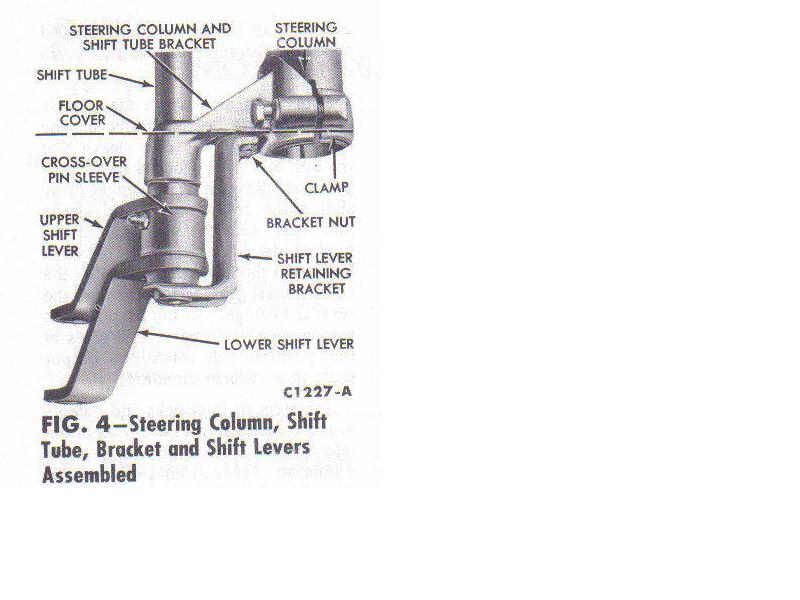

The shift tube is mild steel, the pin and the shift arms are hardened, so,, the shift tube hole wears out.

This allows the pin to end up in different positions, no matter how many times you adjust the shifters. It needs to go up and down into each of the two column shifters without hitting the other one, the slop in the shift tube does not allow it to repeat itself and shift correctly without locking up.... SO, that is the FIRST thing to be addressed.

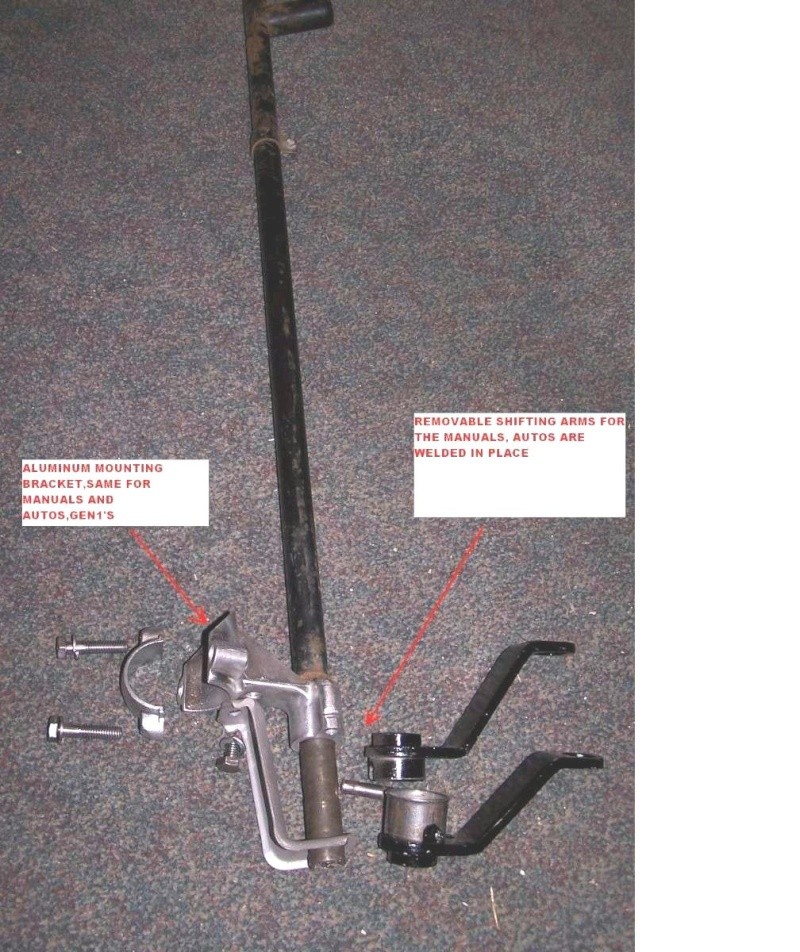

On top of that, the lower z bracket (support bracket) IS NOT INTENDED TO CONTROL ANY SIDE movement, its ONLY FOR VERTICAL SUPPORT,,,,and the upper plastic bushing always gets worn out or stuck!!!! SO,, I make a replacement lower support in my rebuilt columns that uses a bronze bushing that I adapt to ours. Also, I cut the end down, braze it up, and then re cut it to fit the bushing with no slop. Ending up with brass against bronze,,, lasts for ever..

Also, the NEXT spot is the upper support/fulcrum, ours are weak and I replace them with a GENII unit as it is much stronger. The came in the GENII's,, HOWEVER, 99% of them are automatics,,, sorry....

Get all that slop out, and you will be able to adjust it and get a consistent up and down for neutral and not lock it up,,,

vic

BTW,,, THANK YOU GUYS FOR KEEPING MY POSTS AND THE PICTURES,,,,,

MERRY CHRISTMAS TO EVERYONE....