Early Van Brakes and Service Problems.

Forward: Jan 2011

Note: You may need to click on the many pictures in order to get the big picture.

Thanks goes out to the many dedicated Vanners who provided feed back, photos and suggestions.

With much feed back, “collective experience”, research and study; I have accumulated the following information including a few new experience based ideas on service problems people are having with their brakes on the G.

On drum brakes: The drum brakes on the 1st and 2nd gen vans are efficient enough for stock vans with stock size wheels and tires. Like all brakes systems they need regular service. Drum brakes are notorious for uneven and irregular braking when not kept in a good state of repair. To have even braking with drums it is important that the left and right drums on each axle be machined to the same internal diameter as each other to within a tolerance of .010”, and there is a maximum diameter they should not exceed otherwise they shoes will not fit evenly causing erratic braking, and possibly brake fade. Both wheel cylinders must be the same size, freely operate and have no sign of leaks. The return springs must be the same on each side left and right of the axle and each spring must pull its designed tension or uneven braking will result. It is recommended to always replace the springs at any brake shoe replacement time. There is always a leading and a trailing brake shoe, these must be installed in their correct location. The brake adjusters must remain free to adjust and the components of the adjuster mechanism must all be in good operating condition (not worn, bent or stretched). All component contact spots, especially where the shoes touch the backing plates should be kept lubricated with a good anti seize compound. The backing plates themselves should have smooth “pad” surfaces where the shoes contact and move during normal braking. Although these brakes are designed to “self adjust” when braking in reverse, it is not a failsafe system. They can over adjust or not adjust enough depending on how much reverse braking you do. Drum brakes must be adjusted manually when installed, then at 100 or so miles later when seated in, and every 6 months or 800 miles there after, sometimes sooner. Many times pulling brakes are directly due to mal adjustment or worn front end components and incorrect wheel alignment. Uneven tires or tire pressures or offset wheels are a problem and drum brakes always get blamed for the issue. Proper diagnosis of fault is key to keeping cost and frustration to a minimum.

Another Vanner suggests using the newer semi metallic shoes available for drum brakes and claims much better braking. Before I converted to four wheel disc Brakes I had those semi metallic shoes combined on completely rebuilt brake system with the very rare dealer installed “ Hydrovac” booster in my 6 cylinder 90” van. I can attest that combination was almost as good as the disc brakes and I would be quite happy to run that set up again on an ”original restoration” van because they were plenty good enough.

On wheel sizes and disc brakes: Most wheels designed pre 1972 are for drum brakes and will have contact issues when placed on a disc brake vehicle. Most later factory wheels and most aftermarket wheels (but not all) are designed to fit factory disc brake setups with rotors of common diameters. The early G van is not that! It fits into the “but not all category” Not all disc brake designs fit into all disc brake wheels. You must also consider how close the caliper sits to the wheel mounting surface.

After market aluminum or magnesium wheels are more likely to fit a disc system. Some steel wheels that almost fit may just have sloppy gobs of weld that are hitting the caliper and can be cleaned up with a grinder to make clearance: I’m talking about a little clean up here or there, I am not suggesting grinding down the welds. Like wise useless chunks of caliper casting and/or mounting bracket may need to be cleaned off. If you are adamant about using a specific wheel, you can sometimes get away with adding thin wheel spacers. But this has negative effects on steering geometry, alignment and other incurred problems too numerous to mention here.

If you are running 13 “ wheels, your drum brakes will be plenty fine and there is not likely a disc brake set up of adequate braking capacity that will fit into the small space anyway.

14” wheels will generally fit 10.5” rotors (the size used for rear disc brakes); some 14” wheels will fit with 11” or 11.25 ” rotors (the sizes used on the front of vehicles in this weight class).

15” wheels will fit with up to 11.5” rotors and some 15” will fit with 12” rotors.

16” wheels are recommended for 12” rotors.

17” and 18” wheels fit 13” and 14” rotors respectively.

Early disc brake rims tried to open up the inside to make room for the rotor and caliper. This was accomplished by opening up the inside and moving the bead clearance area (drop center) closer to the front, reducing its depth and changing how the wheel disc was welded into the rim.

You can see on this disc brake rim how the inside is opened up and the bead area and mounting center are moved towards the outside.

Aluminum wheels have more clearance because they are machined and there is no need for welding. The bead clearance relief is cut close to the front and the inside becomes one wide open bell. Here is my 15" wheel with an 11" rotor. My wheel will fit a 12" rotor set up but its tight, the balance weights can't be in a certain spot or they hit the caliper.

Here is my 15” wheels with the 11.16” rotor, these wheels fit the 12” rotor set up as well.

Here’s a 14" rim that may not clear some disc brakes.

This 14” slot measures 13.5” across with next to no obstruction and will likely fit many disc brake vehicles.

Many people going to disc brakes on any hotrod will have wheel fit issues.

On these vans so many people have so many different wheels that there is no way to tell if your wheels will fit after changing to disc brakes. You have to just deal with it as it turns out. Try your wheels on another disc application. Or research it before hand. Like I said, some wheels may almost fit and can be cleaned up a little to make fit, others will fit no problems and some will not fit at all.

Additionally; there are some anomalies specific to the early G brake experience.

Brake pedal and linkage:

The first is the brake pedal geometry which is neither best for manual brakes nor power brakes. Its ratio is 5.85:1 which falls in between the two best scenarios and is closer to the preferred manual ratio of 6 to 6.5: 1. Power brakes use 4:1 pedal ratio

The early G pedal must have the rubber bumper at the under side of the floor and the return spring which hooks into the front body panel.

The push rod cam bolt must be adjusted correctly, and can be a different setting depending on what your brake set up (drum/disc/master) is.

Its primary purpose is to eliminate free play in the pedal to master linkage without holding the master piston in at all. The master piston must be allowed to fully return to its seated position up against the snap ring in the master.

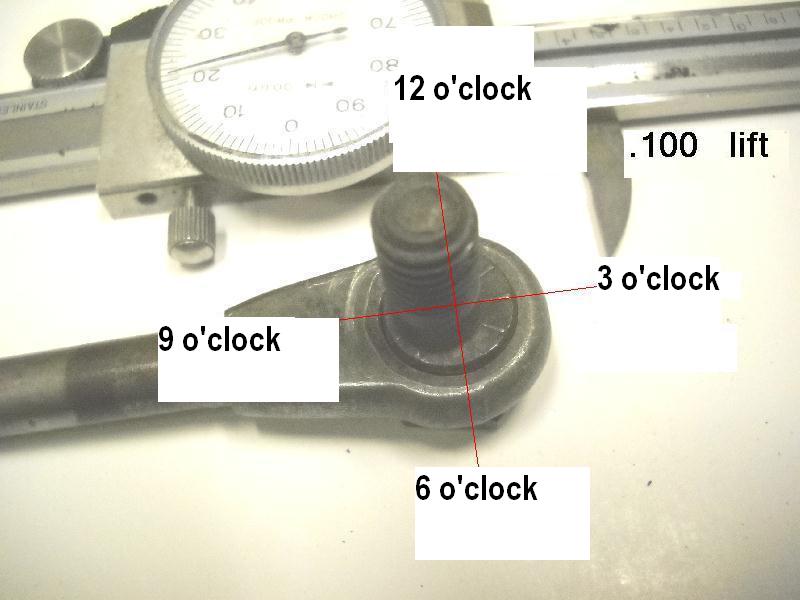

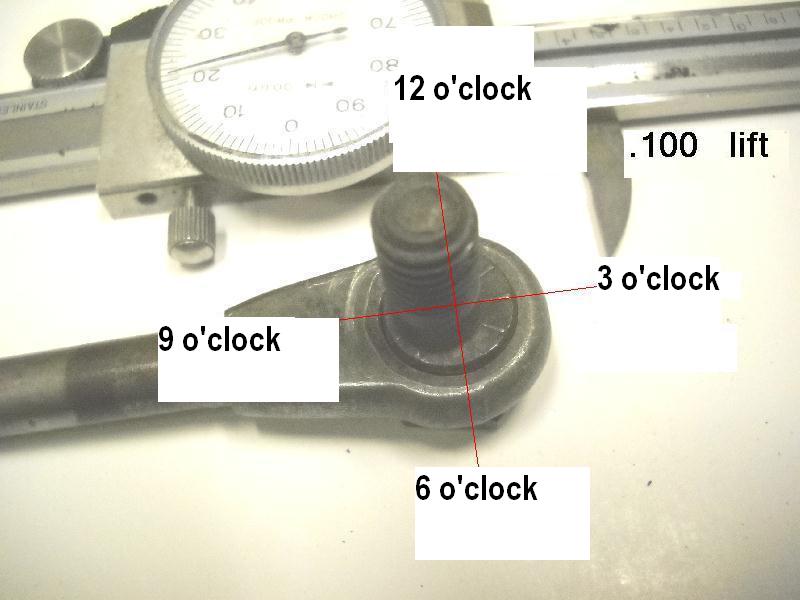

The secondary consideration of adjustment to the cam bolt is the effect on “pedal ratio” it will have depending how you place it. The cam bolt provides an offset of .100” total, that can change the pedal ratio from 5.5:1 to 6.1:1 one way will make the pedal about ½”lower but cause about 60psi (about 10%) more output from the master creating more braking force while the other direction does the opposite. You have to decide which it is you need. It’s easy enough to change, so set it one way and set it the other to experience the driving difference.

Look at it this picture, if you have the cam bolt centered on the 9 o’clock line and you need to rotate it some to remove the free play in the linkage you can move it in one of two different directions to achieve that, UP towards the 12 o’clock position or Down towards the 6. If you rotate the “bolt” to the 12 position so the push rod moves down towards 6, further away from the floor this will decrease the pedal ratio giving a higher pedal but reducing the leverage making for less pressure forced onto the master (“for the same pedal effort”) . Where turning the cam so the push rod becomes closer to the floor, towards 12 o’clock will increase the pedal ratio, will give an increased pedal travel but will increase master output force, increasing braking force.

Brake Bleeding General:

There are many different methods of bleeding brakes and all need different equipment. The best form of brake bleeding was what is used professionally, the “pressure bleeder”. These pressure pots blow the fluid under pressure from the master down and out through each bleeder screws. They can quickly flush the system and remove all air and moisture.

If you don’t have access to a pressure bleeder: I have found the good old one guy on the brake pedal following the instructions of the guy at the bleeder screw to be very successful. There are other designs of bleeding equipment available with varying degrees of pros and cons. Like for example, you can get a cheep “vacuum bleeder” that works with a hand pump. These machines work on the negative (vacuum) principle. Some brake components require positive pressure to seal and will suck air in when under negative pressure. (One of the reasons for residual check valves). On all systems the master cylinder must be “bench bleed” before installation. Hence the term ”bench bleed”, Its not called ”on the van bleed”. The wheels are blead starting with a gravity bleed of all four then a pressure bleed one at a time starting with the wheel closest the master proceeding to the furthest away, then back around all four for a second time.

On brake service and bleeding: There are a couple good articles on bleeding brakes at these links.

http://www.classicperform.com/TechBook/BrakeBleed.htm

http://www.ssbrakes.com/tech-info-faqs/faqs/#installing

http://www.mpbrakes.com/uploads/documents/troubleshootingpdf.pdf

http://tsmmfg.com/Troubleshooting.htm

Caliper bleeding: Another big problem with the various disc brake conversions is the multitude of different calipers being used, compounded by the very limited placement of those calipers onto the G, lends to their bleeder screw not being strait up at the 12 o’clock position. This occurs with store bought “disc brake Kits” as well. This makes for the possibility of entrapped air that can only be bleed out by repositioning the caliper during the bleeding process. This is accomplished buy removing the caliper from the rotor, stuffing a 1” thick piece of wood between the pads (or clamping the piston into its bore) and holding the caliper upright while bleeding.

Like this.

or this.

A problem Not so good!

At least three mechanically experienced Vanners I have heard from thought they had all the air out until they did this procedure to find , “Yes” there was entrapped air. They have reported “one air bubble from each caliper and now the pedal is 1.5 to 2” higher”. It only takes one trapped bubble to make your pedal drop more then an inch, and breaking force is substantially reduced as well.

Another problem some are encountering is “Low brag calipers”. Low drag calipers started around 1980 where the piston ring groove was cut to 30* instead of 15* which caused the calipers to retract two to three times as much as previous calipers. This was to improve fuel economy. These calipers usually require a “quick take up master” which has a two stage bore and internal valves. These masters have a large bore of around 1.5” to flow copious amounts of fluid to the caliper, once the caliper/pads push up against the rotor and create back pressure the valve in the master switches the flow to a standard 1” or 1.125” bore to apply the required fluid pressure. The main problem is the caliper rebuild market is flooded with both type calipers coming in under the same part numbers and there is no way to ID which is which by looking at them assembled. So suppliers can’t tell you what is in the box and you don’t know what you have unless you do a certain test on your van. (Test found in following link). One vanner who did the test claims to have one of each because when the pedal is released one wheel has noticeably more released then the other.

http://www.mpbrakes.com/uploads/documents/lowdrag.pdf

On Caliper mounting:

Floating calipers like the ones used on our vans must”float”. Meaning they must be completely free to slide in and out with only the resistance offered by the “O rings” sliding on the clean caliper guide pins.

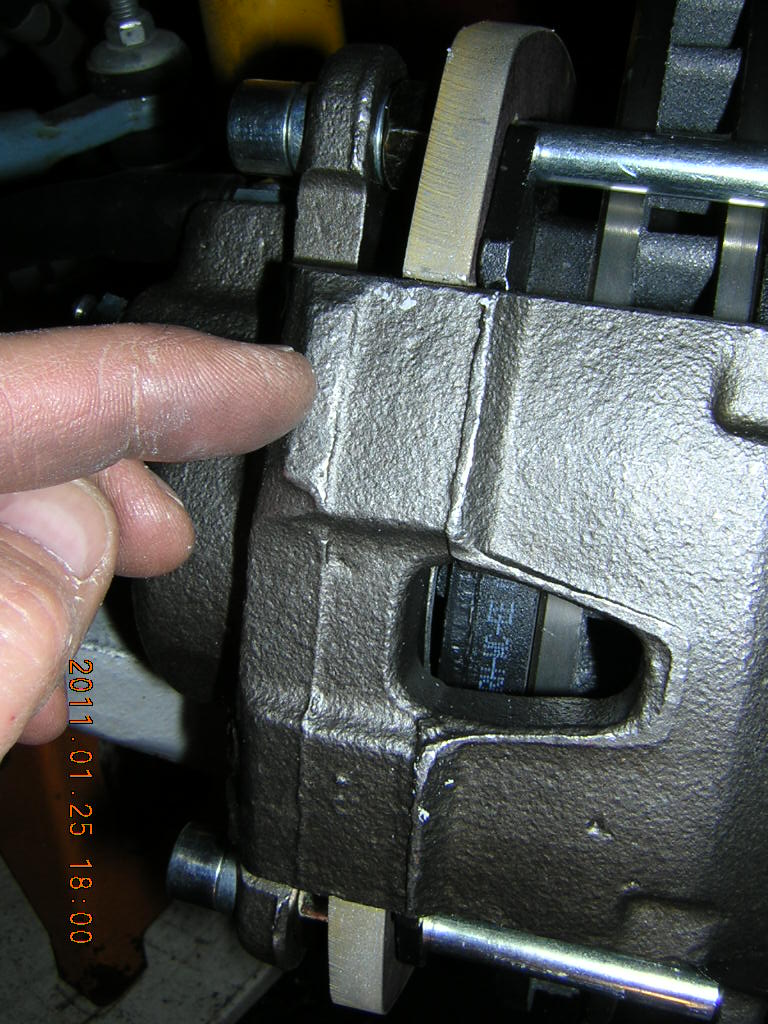

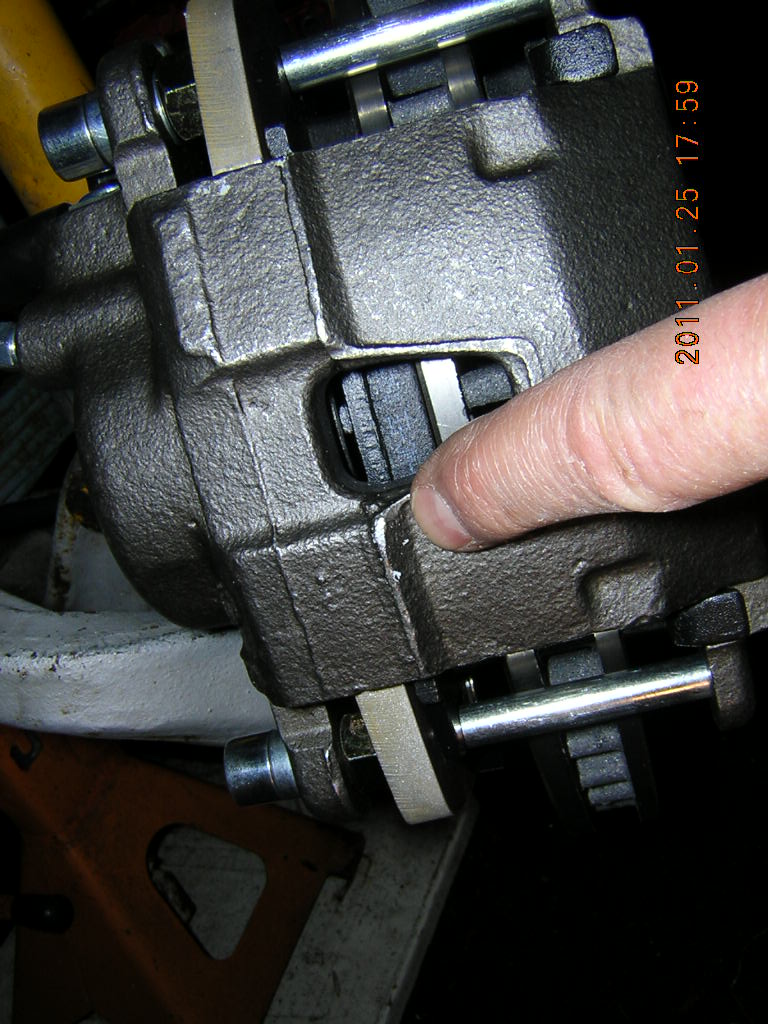

Look at this failure: As this caliper was installed, the final bolt installation puller the caliper up tight against the bracket.

The bracket needed to be filed a bit to allow for almost touching but about .005” clearance.

Like this.

Try this inspection test: When you friend steps hard on and off the brake pedal; you should be able to see the caliper move slightly to and fro. The bracket should not ever move at all with the caliper, if it does the caliper if hanging up and dragging the bracket with it. That will make for a low brake pedal and other braking problems guaranteed!

On rotors, run out, shims and spacers. Sometimes a low disc brake pedal is caused by a rotor issue where the rotor is pushing the caliper piston back too far. Called “knock back”. The larger the diameter of the rotor, the more sensitive it becomes to all problems and the margin for error becomes less. Knock back is often caused by loose wheel bearing adjustment, rotors with excessive run out or in the case of rear disc brakes, the axles are moving in and out of the rear end too much causing the rotor to push the caliper piston in too far.

With your van front wheel jacked up, grab the wheel at the top and bottom and rock the top and bottom in and out slowly but firmly and deliberately, if there is any play noticed, your wheel bearings are too loose or worn out. This play will be hugely greater under the load of the van turning a corner and will push the caliper piston in too much. The rear disc brake axle should move straight in and out some; usually .050”, you need to check the specs for the type of rear end you have.

This knock back problem is seriously amplified if the caliper is not 100% free to float on the bracket without restriction.

On hat type rotors that slide over the hub several things can cause/add to knock back but can usually be rectified without machining the rotor. The rotor may have excess run out or its mounting onto the hub is not square or the hub itself may be warped. (Another vanner measured his and found one rotor to wobble by .011” and it was the hub that was warped.) In the above cases the common practice today is to reposition the rotor onto any or all of the five different stud positions for best fit, or place correction shims between the rotor and the hub to correct the problem. These shims are available to correct .003”, .006” and .009” at parts jobber stores. UAP NAPA part number is BA80303, BA 80306 and BA80309 respectively.

http://www.napaonline.com/Search/Detail.aspx?R=UBPBA80309_0163777026

Measuring rotor run out applies to all rotor types.

With all five nuts torqued evenly holding the hat type rotor in place on the hub, not applicable to solid one piece Nova rotor.

Using a clamp type or magnetic base dial indicator attached to the caliper mount.

(You can rent or borrow one)

Set the dial indicator to measure the middle of the pad contact area and rotate the rotor 360*. Find the difference between the lowest and the highest readings.

11” rotors are permitted .004” max and 12” rotors are permitted .002” max run out.

If your rotor exceeds this run out tolerance it must be corrected.

The one piece rotor will have to be removed and machined true or replaced.

The hat type rotor can be trued by you in your drive way and usually just gets replaced if its too far out because they are cheaper to replace then machine and a machined rotor is not so desirable anyway as its mass is reduced making it have less braking potential.

Correcting run out on the hat type (type K) rotor. You will have to do this only once if done correctly. With the rotor held in place by five evenly torqued nuts. Using a Chalk, mark the rotor and a stud to index your starting point. Remove and install the rotor in all five different stud locations and re-measure at each location as describe above. Make sure the hub and rotor mating faces are clean and free of any bents or burrs that might cause the rotor to be held up. Record your findings in each position on a note pad. Once you have found the best fit, permanently mark the rotor and one stud tip with a paint mark to retain this indexed location should the rotor ever have to be removed.

If at this best fit location your rotor still exceeds the max run out tolerance you will have to purchase a shim (see above) of the closest amount to bring the rotor true.

Note: think about this: the shims come in correction factors of .003”, .006” and .009” run out. You have five different stud positions to choose from and the shim can be placed in five different positions as well. That means you now have twenty five different choices for best fit. If you look at the measurement notes you took during the check you can mathematically choose a shim and stud position combination to bring almost any rotor into near perfect running. If the run out exceeds .013” in the” best position” with no shim: either the rotor is too warped and a replacement is necessary or you have a hub and/or wheel bearing problem. A quick check using the other rotor as a test (because you have two)will tell you if it’s the rotor or the hub that is problematic.

On designing a brake system: I constantly hear from vanners, is there a “disc brake kit”? The short answer is No! so stop asking. The reasons are as follows. These vans are all different; no two are alike as you will see in the following text. I originally designed the M1D bracket and provided a list of optional calipers, brake hoses and installation options to try to accommodate the many variables that exist through out our vans. That didn’t work out so well because many people had no clue on what to choose or why to choose it. So I am designing three different disc brake brackets that work on “my van”. I will provide a parts list of a single rotor, caliper and hose for each to make it simple. You only have to choose which set up you want. One will use a one piece 11” rotor and be the easiest to install. This will be available in a manufactured bracket or as a template for the budget minded at home fabricator. The second will use an 11.16” hat type rotor, a little better system, a little cheaper then the former but more work to install. The third will be a 12” hat type rotor and even more cost and work to install. Additional to any of those will be “what are you planning for rear brakes” and “what is your van” and “are you planning power brakes” , do you “have a sway bar” that will lead into what you have to do about a master cylinder and proportioning and other valves.

If you would like to design a brake system specific to your van you need the following information.

Max GVWR

Static weight on the front axle

Static weight on the rear axle

Maximum deceleration rate expected (typically between 1.0 to 1.5g for sedan or sports cars, unit less)

Center of gravity height (go online to learn methods of determining using corner weight scales)

Wheelbase

Disc/disc, disc/drum?

Tire rolling diameter (you can use the tire diameter) of both front and rear if not the same.

Tire pressures

Coefficient of friction of the tires. “Traction rating”.

The size/area of each caliper piston and/or wheel cylinder.

Type of suspension used, springs and shocks.

% of weight transfer from one axle to the other during max braking. “Brake shift”

Rotor sizes and/or drum size

Pad and shoe surface area and coefficient of friction.

Target foot pressure

Pedal ratio

Boost multiplication product

Master cylinder piston area.

OK! That’s not the whole list but I will stop there, show me two of our vans that have the same values, or even the same tires!

This is one of the many reasons why there is no “kit”. Anybody who wants to upgrade their van brakes should educate themselves with some basic knowledge before getting into it. You don’t have to be an engineer but changing the brake system on your van is not an out of the box “bolt on thing”. That being said, many of those so called bolt on brake kits from popular after market name brand suppliers in most all cases require additional modifications to be installed and some need way more work then what it takes to do disc brakes on these vans.

Here are a few “get you started” links if you want to go the 9 yards on designing your brake system.

http://www.hotrodheaven.com/tech/brakes/

http://www.stoptech.com/tech_info/PedalSetup-DualMaster-Guide.pdf

http://www.engineeringinspiration.co.uk/brakecalcs.html

http://www.cheapsportscar.net/hydraulics.php

If you want disc brakes as simple as possible; the Nova rotor set up and a disc/drum configuration using the early corvette master cylinder, two residual valves and an adjustable proportioning valve. That’s as simple as it gets. You will have to do other changes according to your vans needs.

On proportioning and valves: (Sometimes called “Hold off valves” or “Metering blocks”}

Actual “Proportioning” is affected by many factors, in fact about everything on that above list affects brake proportioning. The proportioning valve is intended to bring correction to braking imbalance inherent in all vehicles. In order to make that happen correctly; factory proportion valves are very vehicle specific and sensitive to the needs of that vehicle it was designed for. Proportioning valves don’t actually reduce the “pressure” to the rear brakes, they slow the rate at which the rear brakes will get up to the same pressure as the front brakes. Some proportioning valves are simply a calibrated drilled hole that restricts flow rate and higher quality valves are a spring loaded plunger on a seat. Either way, they are made for a specific vehicle. The one size fits all proportioning valves sold by leading aftermarket suppliers are no better a choice then using a valve off any other vehicle. They might be reasonably close but chances of them being right is about as likely as winning the lottery. I recommend an adjustable proportioning valve for all brake system modifications to both 1st and 2nd gen vans. An added feature to an adjustable valve is you can change it to what you need; like an empty van vs. a fully loaded or towing a trailer in the mountains or tire size change.

On residual valves: Residual valves are necessary, the drum brakes need a 10 lb residual valve to keep the cylinder seals spread and the shoes ready to apply. The Disc brakes need a 2 lb valve to keep the pads ready to apply. These valves keep the fluid system partially pressurized which aids in a higher brake pedal. Another reason for residual valves is to keep the fluid from gravity feeding back to the master cylinder which is a particular problem when the master is near the same height as the wheels like on the early G. Only one residual valve is used per circuit (one for the front and one for the rear) They should be mounted right outside the master cylinder and before any other valves or “T”s.

You will know if you need one of these valves if you have to pump the pedal twice to get a good pedal.

On master cylinders: No matter what brakes your van has these guys have a master for it.

http://www.tuffstuffperformance.com/index.cfm/page/ptype=results/Category_ID=210/home_id=206/mode=cat/cat210.htm

There are several different master cylinders that could be used depending on what your van is and what braking performance you would like. To keep it simple, we like the early corvette master because it has a low profile that fits well in the stock van master location. (the 1st gen requires additional mods) and it has no internal residual valves.

Size: these masters are available in 1” bore and 1.125” bore. Let’s say your foot pushes 100lbs force, the 1” bore is easier to apply to full brakes but will travel further down. The 1.125” bore conversely will be harder to apply full brakes but will have a higher pedal. These days it is very likely you will get “low drag” calipers. These calipers sometimes need to have a “Quick take up master” which will give a higher brake pedal by design. To date there has not been enough experimentation with quick take up masters on our vans to recommend which to use. They are available for 1985 ½ ton trucks and Blazers and such in both 1” and 1.125”. Disc/drum masters usually have a built in 10lb residual check valve for the drum brakes and no valve for the disc side. I could assist any one willing to experiment with this type of master. Because of the design and ratio of the van brake pedal, the 1” feels like it travels too far and the 1.125” feels a bit too hard. One thing is for sure: we are talking manual disc brakes in a vehicle with an old school style brake pedal geometry. Drop all your expectations right now! Because disc brakes in you vintage van is not going to feel anything like your 2008 Chevy Malibu.

On power brake boosters; Conventional Brake boosters that go between the pedal and the master do not boost brake pressure. What they do is make the pedal easier to push. The boosters that have a separate cylinder attached and fit into the hydraulic system do boost pressure. Installing the conventional type booster in our vans requires re-locating the master cylinder to some other place and making a linkage to connect it to the pedal. This takes above average fabrication and design skills. I have done a power brake conversion on my 65. I had the original “Bendix Hydro-Vac” booster with the drum brakes on my 65 it was a dealer installed item and I have to say made the brakes dam near as good as my disc brakes. There is also Hydroboost driven off a PS pump and there is also electrically powered brake boosters.

Here is something you might consider:

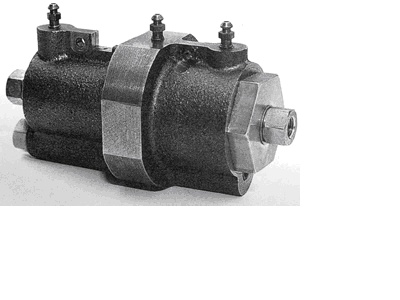

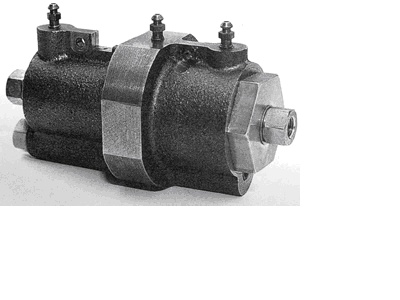

The EC-1500 Hydraulic pressure multiplier from ECI.

On brake lines and hoses: It is best to use the smallest diameter and hardest lines possible. 3/16” steel seamless line is recommended for our vans. All lines and hoses more then ten years old should be replaced and fluid should be changed every two years to reduce internal corrosion and sludge build up in lines. Any steel brake lines more then 25 years old is plane suicidal. Change then all out for new. Brake lines can be stainless steel and galvanized steel, any other metal is not tough enough for the job. Stainless steel is much harder to flair and work with but much higher quality that does not corrode. The least amount of connections the better. The best flex hoses are the steel braided hose with a nylon internal tube because they resist swell under high braking pressure which aids in a better feeling pedal. Rubber flex hoses like the factory type are acceptable. Hoses must be DOT approved for road use. Flex hoses need to make bends yes, but they should be installed in such a way that they do not twist. They have a straight line painted on them to aid in proper installation. Twisted hoses will come loose as they try to untwist under pressure and also cause excessive pedal travel. You want the shortest line possible but it must be long enough to handle full suspension extension and full turns both ways simultaneously.

On front disc brake conversion:

Front disc brakes are probably the single best improvement that can be done to these vans, seconded only by the conversion of the 1st gen to a duel circuit brake system. There are several different front disc brake setups in use for these vans. All with proven degrees of successes and failures. Some take more additional van mods to install, some change the steering geometry more then others and some are simply harder to do then others. I have listed three such set ups at the end of this article. There is one after market supplier providing “a kit” as they call it which requires considerably more van modifications then any other bracket made for these vans, uses the smaller metric caliper and requires machining of some steering components and changes the steering geometry allot.

Converting the front axle to disc brakes will cost about $500 and up depending on what quality and grade of components you buy. You will then have to convert to a duel circuit master cylinder for disc brakes, add proportioning and residual check valves, do lines, hoses and fluid flush for another $250 or so. You might convert to rear discs for about another $500 or just spend $100 bringing you rear drum brakes up to service standard.

On rear disc brakes;

The first question would be why do you want them? 9” drum brakes are plenty braking for the back of these vans. 10.5” rotors are as large as you could ever use, anything larger will not get used enough and the rotors will always look rusty. Have a look at any car show, there are lots of rear disc vehicles with rusty rear rotors, those cars are not using their rear brakes enough which is dangerous and shame full. The axle flanges will have to be machined down to fit into the hat type rotor. Rear disc brakes present another low pedal potential and other maintenance headaches. They are particularly sensitive to the knock back caused by calipers unable to free-float enough because the axles move in and out quite a bit. The posi rear ends are said to be worse for this problem but that’s not my experience. I have found a good tight posi rear end to have less axle movement. If there is any hang up of the caliper on the bracket the axles will just push the piston into the caliper resulting in a very low pedal. There is also a particular installation and initial adjustment that must be done correctly at the time of bleeding brakes. Failure to follow said instructions will leave a piss/poor pedal feel. See link: http://www.classicperform.com/TechBook/BrakeBleed.htm

The rear calipers adjust off the parking brake. The parking brake is incorporated into the caliper piston. You must set the parking brake every time you park the van. The rear caliper pitons utilize a one way clutch inside the caliper piston. When the parking brake is applied the clutch senses when there is .030" or more clearance between the friction material and the rotor on the inboard side. When there is more than .030" the clutch turns inside the piston adjusting it out keeping the rear brakes adjusted. If you do not set your parking brake every time you will start to lose brake pedal (low and spongy) and the adjuster mechanism will not work any longer. Also: never use rebuilt calipers on the rear because the re-builders use the old pistons and the pistons were the reason the caliper failed in the first place.

On calipers: There are basically two calipers that are used when modifying vehicles the weight of our vans. The most common to use on the front is the standard 7” mount caliper, it has an almost 3” piston and uses the # 728 pads. These are used by GM on most ½ ton and ¾ ton PU trucks, vans and cars of the same weight class. They come in a variety of different part numbers and that is a reflection of the many different hose attachment and bleed screw configurations they can be had in.

On the rear disc brakes a smaller caliper known as the “metric” caliper uses the # 7070 pad. Ironically it is not actually smaller on the outside. This metric caliper comes with a variety of piston sizes and should be selected according to “proportioning” needs. The metric caliper comes with a built in park brake mechanism for rear use or without as a plane caliper when used on the front of lighter vehicles. Sometimes these smaller calipers are used on the front of heavier vehicles like our vans and that can be made to work if the master cylinder bore size is matched up to use this smaller piston caliper. Braking effectiveness can be the same under normal braking but because of the smaller pad surface area these metric calipers are likely to eat up pads when used on heavier then intended vehicles and will likely heat soak and crystallize under very heavy braking conditions while on a vehicles of 4700 GVWR or higher. The one advantage to using these metric calipers is that they are somewhat lighter then the standard 7” mount caliper.

On Brake fluid:

D.O.T. 3 brake fluid is the longest running proven fluid for your street van. This fluid is recommended to be flush changed every two years. A can of DOT 3 that has had the lid off it for a day is garbage, especially if in a humid environment. This is because this fluid is hydroscopic (sucks moister out of the air). When DOT 3 fluid achieves 3% moisture by volume it is unsafe to use. DOT 3 is cheep, has anti aeration properties, modern DOT 3 has corrosion inhibiters and is designed for your street van. In the old days, used DOT 3 fluid was boiled on the stove top to remove moisture then filtered and re-used because it was expensive and hard to get in some places, they still do that in some places today.

There is lots of talk about synthetics, DOT 7 and alike. There is a lot of people talking but most are just lip flapping what some sales brochure says, few actually know!

I have information from the brake engineer who designs and maintains the $45.000 brake system on a friends formula race car.

These often called “High performance” brake fluids have pros and cons. They are a different fluid with different qualities designed for different applications. The primary advantage for these synthetic fluids are their intended temperature range. Your brake rotors are not going to be glowing at 2300* for four hours while you run your van in the Daytona 500.

The down side to these synthetic brake fluids made for high temp use is that they are “Not” hydroscopic, meaning they do not absorb moisture. This means the regular condensation accumulation and moisture ingestion that happens in brake systems with normal street driving will accumulate in the calipers and cylinders as water droplets or as an emulsion. During highway braking these water droplets can boil and turn into steam bubbles and your pedal suddenly gets spongy or goes to the floor and you loose about 90% of your braking ability. After your accident your insurance broker and the police claim you are a reckless driver because when they try the pedal, the steam has cooled down and returned to water drops and your pedal feels fine to them.

Because of this problem, manufacturers state! if you run synthetic brake fluid in your street vehicle it is recommended the complete system be flushed with new fluid every three months.

Another fact about synthetic fluid is, it is some what compressible and always makes for a spongier pedal compared to DOT 3.

Synthetic fluid is also subject to aeration and so bleeding has to handled with greater care.

D.O.T. 3 brake fluid is designed for what we do, using other fluids will not improve your vans braking performance.

On brake pads: There are several different types of brake pads available for most any caliper. Primarily the difference is the “coefficient of friction” the pad material has when at its design operating temperatures. One other difference is some of the cheaper pads are on thinner backing plates which may flex under compression adding to a spongy pedal feel.

Brake pads made for racing and “High performance applications” do their best grabbing at temperatures higher then your van brakes will ever get. These pads will have poor braking effectiveness at normal street driving temperatures. You want a good quality but standard semi organic every day bone stock brake pads for your van, they are designed to grab best at lower brake temperatures like your van will be doing in 99% of its braking life.

I hesitate to say cheaper pads are best only because you also want a strong steel back plate on the pad. So middle priced regular replacement pads are what will work best on our vans.

If you really want an upgrade in pads try the factory police and service vehicle pad. Available to replace the # 728 pad these # 7506M pads have a larger stronger steel backing plate and have about 20% more pad contact area. They should fit right into the BZ bracket, and the M1DK10N bracket and will fit the bent M1D bracket with a minor grinding to the lower corners of the inside pad. See photos below.

Look how they compare to the standard brake pad on the left.

With minor clearance grinding they will fit onto the original M1D bracket and the newer M1D80TA bracket. They need to clear at the bend line of the bracket so the inner pad will sit flat and may need the inner most corners ground away a bit to permit a parallel seating.

On parking brakes: Once upon a time these cable powered brakes were called emergency brakes because that was a time in history when the tried and trusted cable brakes were being replaced with the very unreliable “New” hydraulic brakes. They were kept on because that’s all you had to stop with once your single line brake system developed a leak and failed. Today these are called parking brakes because they hold OK and resist forward movement of the static vehicle when parked (drum brakes). Caliper park brakes hold the same in either forward or reverse direction. If you ever tried pulling on your park brake while going down the high way you will discover why realistic auto designers do not call them emergency brakes. Parking brakes on most all vehicles also double as a brake adjuster and therefore should or must be used every time you park the vehicle. Our vans have a rather primitive pulley and cable system for the park brake with a not so friendly to use handle. The virtue of this primitiveness is replacement cable can by fabricated up as easily as installing a clothes line. Many persons customize there park brake to newer style cables and handles. If you go to rear disc brakes you will have to modify your park brake system to something effective. I used the Corvair dash mount handle and mounted it on the floor of my van with modern type cables. It works easy and well. Two things I like about this handle positioned where I have it, is the handle hits the back of my leg disrupting my foot from being on the gas pedal comfortably when the brake is on, and, this brake handle is way easier on my back to engage.

Hope this comes as helpfull.

Thank you

M1d

Forward: Jan 2011

Note: You may need to click on the many pictures in order to get the big picture.

Thanks goes out to the many dedicated Vanners who provided feed back, photos and suggestions.

With much feed back, “collective experience”, research and study; I have accumulated the following information including a few new experience based ideas on service problems people are having with their brakes on the G.

On drum brakes: The drum brakes on the 1st and 2nd gen vans are efficient enough for stock vans with stock size wheels and tires. Like all brakes systems they need regular service. Drum brakes are notorious for uneven and irregular braking when not kept in a good state of repair. To have even braking with drums it is important that the left and right drums on each axle be machined to the same internal diameter as each other to within a tolerance of .010”, and there is a maximum diameter they should not exceed otherwise they shoes will not fit evenly causing erratic braking, and possibly brake fade. Both wheel cylinders must be the same size, freely operate and have no sign of leaks. The return springs must be the same on each side left and right of the axle and each spring must pull its designed tension or uneven braking will result. It is recommended to always replace the springs at any brake shoe replacement time. There is always a leading and a trailing brake shoe, these must be installed in their correct location. The brake adjusters must remain free to adjust and the components of the adjuster mechanism must all be in good operating condition (not worn, bent or stretched). All component contact spots, especially where the shoes touch the backing plates should be kept lubricated with a good anti seize compound. The backing plates themselves should have smooth “pad” surfaces where the shoes contact and move during normal braking. Although these brakes are designed to “self adjust” when braking in reverse, it is not a failsafe system. They can over adjust or not adjust enough depending on how much reverse braking you do. Drum brakes must be adjusted manually when installed, then at 100 or so miles later when seated in, and every 6 months or 800 miles there after, sometimes sooner. Many times pulling brakes are directly due to mal adjustment or worn front end components and incorrect wheel alignment. Uneven tires or tire pressures or offset wheels are a problem and drum brakes always get blamed for the issue. Proper diagnosis of fault is key to keeping cost and frustration to a minimum.

Another Vanner suggests using the newer semi metallic shoes available for drum brakes and claims much better braking. Before I converted to four wheel disc Brakes I had those semi metallic shoes combined on completely rebuilt brake system with the very rare dealer installed “ Hydrovac” booster in my 6 cylinder 90” van. I can attest that combination was almost as good as the disc brakes and I would be quite happy to run that set up again on an ”original restoration” van because they were plenty good enough.

On wheel sizes and disc brakes: Most wheels designed pre 1972 are for drum brakes and will have contact issues when placed on a disc brake vehicle. Most later factory wheels and most aftermarket wheels (but not all) are designed to fit factory disc brake setups with rotors of common diameters. The early G van is not that! It fits into the “but not all category” Not all disc brake designs fit into all disc brake wheels. You must also consider how close the caliper sits to the wheel mounting surface.

After market aluminum or magnesium wheels are more likely to fit a disc system. Some steel wheels that almost fit may just have sloppy gobs of weld that are hitting the caliper and can be cleaned up with a grinder to make clearance: I’m talking about a little clean up here or there, I am not suggesting grinding down the welds. Like wise useless chunks of caliper casting and/or mounting bracket may need to be cleaned off. If you are adamant about using a specific wheel, you can sometimes get away with adding thin wheel spacers. But this has negative effects on steering geometry, alignment and other incurred problems too numerous to mention here.

If you are running 13 “ wheels, your drum brakes will be plenty fine and there is not likely a disc brake set up of adequate braking capacity that will fit into the small space anyway.

14” wheels will generally fit 10.5” rotors (the size used for rear disc brakes); some 14” wheels will fit with 11” or 11.25 ” rotors (the sizes used on the front of vehicles in this weight class).

15” wheels will fit with up to 11.5” rotors and some 15” will fit with 12” rotors.

16” wheels are recommended for 12” rotors.

17” and 18” wheels fit 13” and 14” rotors respectively.

Early disc brake rims tried to open up the inside to make room for the rotor and caliper. This was accomplished by opening up the inside and moving the bead clearance area (drop center) closer to the front, reducing its depth and changing how the wheel disc was welded into the rim.

You can see on this disc brake rim how the inside is opened up and the bead area and mounting center are moved towards the outside.

Aluminum wheels have more clearance because they are machined and there is no need for welding. The bead clearance relief is cut close to the front and the inside becomes one wide open bell. Here is my 15" wheel with an 11" rotor. My wheel will fit a 12" rotor set up but its tight, the balance weights can't be in a certain spot or they hit the caliper.

Here is my 15” wheels with the 11.16” rotor, these wheels fit the 12” rotor set up as well.

Here’s a 14" rim that may not clear some disc brakes.

This 14” slot measures 13.5” across with next to no obstruction and will likely fit many disc brake vehicles.

Many people going to disc brakes on any hotrod will have wheel fit issues.

On these vans so many people have so many different wheels that there is no way to tell if your wheels will fit after changing to disc brakes. You have to just deal with it as it turns out. Try your wheels on another disc application. Or research it before hand. Like I said, some wheels may almost fit and can be cleaned up a little to make fit, others will fit no problems and some will not fit at all.

Additionally; there are some anomalies specific to the early G brake experience.

Brake pedal and linkage:

The first is the brake pedal geometry which is neither best for manual brakes nor power brakes. Its ratio is 5.85:1 which falls in between the two best scenarios and is closer to the preferred manual ratio of 6 to 6.5: 1. Power brakes use 4:1 pedal ratio

The early G pedal must have the rubber bumper at the under side of the floor and the return spring which hooks into the front body panel.

The push rod cam bolt must be adjusted correctly, and can be a different setting depending on what your brake set up (drum/disc/master) is.

Its primary purpose is to eliminate free play in the pedal to master linkage without holding the master piston in at all. The master piston must be allowed to fully return to its seated position up against the snap ring in the master.

The secondary consideration of adjustment to the cam bolt is the effect on “pedal ratio” it will have depending how you place it. The cam bolt provides an offset of .100” total, that can change the pedal ratio from 5.5:1 to 6.1:1 one way will make the pedal about ½”lower but cause about 60psi (about 10%) more output from the master creating more braking force while the other direction does the opposite. You have to decide which it is you need. It’s easy enough to change, so set it one way and set it the other to experience the driving difference.

Look at it this picture, if you have the cam bolt centered on the 9 o’clock line and you need to rotate it some to remove the free play in the linkage you can move it in one of two different directions to achieve that, UP towards the 12 o’clock position or Down towards the 6. If you rotate the “bolt” to the 12 position so the push rod moves down towards 6, further away from the floor this will decrease the pedal ratio giving a higher pedal but reducing the leverage making for less pressure forced onto the master (“for the same pedal effort”) . Where turning the cam so the push rod becomes closer to the floor, towards 12 o’clock will increase the pedal ratio, will give an increased pedal travel but will increase master output force, increasing braking force.

Brake Bleeding General:

There are many different methods of bleeding brakes and all need different equipment. The best form of brake bleeding was what is used professionally, the “pressure bleeder”. These pressure pots blow the fluid under pressure from the master down and out through each bleeder screws. They can quickly flush the system and remove all air and moisture.

If you don’t have access to a pressure bleeder: I have found the good old one guy on the brake pedal following the instructions of the guy at the bleeder screw to be very successful. There are other designs of bleeding equipment available with varying degrees of pros and cons. Like for example, you can get a cheep “vacuum bleeder” that works with a hand pump. These machines work on the negative (vacuum) principle. Some brake components require positive pressure to seal and will suck air in when under negative pressure. (One of the reasons for residual check valves). On all systems the master cylinder must be “bench bleed” before installation. Hence the term ”bench bleed”, Its not called ”on the van bleed”. The wheels are blead starting with a gravity bleed of all four then a pressure bleed one at a time starting with the wheel closest the master proceeding to the furthest away, then back around all four for a second time.

On brake service and bleeding: There are a couple good articles on bleeding brakes at these links.

http://www.classicperform.com/TechBook/BrakeBleed.htm

http://www.ssbrakes.com/tech-info-faqs/faqs/#installing

http://www.mpbrakes.com/uploads/documents/troubleshootingpdf.pdf

http://tsmmfg.com/Troubleshooting.htm

Caliper bleeding: Another big problem with the various disc brake conversions is the multitude of different calipers being used, compounded by the very limited placement of those calipers onto the G, lends to their bleeder screw not being strait up at the 12 o’clock position. This occurs with store bought “disc brake Kits” as well. This makes for the possibility of entrapped air that can only be bleed out by repositioning the caliper during the bleeding process. This is accomplished buy removing the caliper from the rotor, stuffing a 1” thick piece of wood between the pads (or clamping the piston into its bore) and holding the caliper upright while bleeding.

Like this.

or this.

A problem Not so good!

At least three mechanically experienced Vanners I have heard from thought they had all the air out until they did this procedure to find , “Yes” there was entrapped air. They have reported “one air bubble from each caliper and now the pedal is 1.5 to 2” higher”. It only takes one trapped bubble to make your pedal drop more then an inch, and breaking force is substantially reduced as well.

Another problem some are encountering is “Low brag calipers”. Low drag calipers started around 1980 where the piston ring groove was cut to 30* instead of 15* which caused the calipers to retract two to three times as much as previous calipers. This was to improve fuel economy. These calipers usually require a “quick take up master” which has a two stage bore and internal valves. These masters have a large bore of around 1.5” to flow copious amounts of fluid to the caliper, once the caliper/pads push up against the rotor and create back pressure the valve in the master switches the flow to a standard 1” or 1.125” bore to apply the required fluid pressure. The main problem is the caliper rebuild market is flooded with both type calipers coming in under the same part numbers and there is no way to ID which is which by looking at them assembled. So suppliers can’t tell you what is in the box and you don’t know what you have unless you do a certain test on your van. (Test found in following link). One vanner who did the test claims to have one of each because when the pedal is released one wheel has noticeably more released then the other.

http://www.mpbrakes.com/uploads/documents/lowdrag.pdf

On Caliper mounting:

Floating calipers like the ones used on our vans must”float”. Meaning they must be completely free to slide in and out with only the resistance offered by the “O rings” sliding on the clean caliper guide pins.

Look at this failure: As this caliper was installed, the final bolt installation puller the caliper up tight against the bracket.

The bracket needed to be filed a bit to allow for almost touching but about .005” clearance.

Like this.

Try this inspection test: When you friend steps hard on and off the brake pedal; you should be able to see the caliper move slightly to and fro. The bracket should not ever move at all with the caliper, if it does the caliper if hanging up and dragging the bracket with it. That will make for a low brake pedal and other braking problems guaranteed!

On rotors, run out, shims and spacers. Sometimes a low disc brake pedal is caused by a rotor issue where the rotor is pushing the caliper piston back too far. Called “knock back”. The larger the diameter of the rotor, the more sensitive it becomes to all problems and the margin for error becomes less. Knock back is often caused by loose wheel bearing adjustment, rotors with excessive run out or in the case of rear disc brakes, the axles are moving in and out of the rear end too much causing the rotor to push the caliper piston in too far.

With your van front wheel jacked up, grab the wheel at the top and bottom and rock the top and bottom in and out slowly but firmly and deliberately, if there is any play noticed, your wheel bearings are too loose or worn out. This play will be hugely greater under the load of the van turning a corner and will push the caliper piston in too much. The rear disc brake axle should move straight in and out some; usually .050”, you need to check the specs for the type of rear end you have.

This knock back problem is seriously amplified if the caliper is not 100% free to float on the bracket without restriction.

On hat type rotors that slide over the hub several things can cause/add to knock back but can usually be rectified without machining the rotor. The rotor may have excess run out or its mounting onto the hub is not square or the hub itself may be warped. (Another vanner measured his and found one rotor to wobble by .011” and it was the hub that was warped.) In the above cases the common practice today is to reposition the rotor onto any or all of the five different stud positions for best fit, or place correction shims between the rotor and the hub to correct the problem. These shims are available to correct .003”, .006” and .009” at parts jobber stores. UAP NAPA part number is BA80303, BA 80306 and BA80309 respectively.

http://www.napaonline.com/Search/Detail.aspx?R=UBPBA80309_0163777026

Measuring rotor run out applies to all rotor types.

With all five nuts torqued evenly holding the hat type rotor in place on the hub, not applicable to solid one piece Nova rotor.

Using a clamp type or magnetic base dial indicator attached to the caliper mount.

(You can rent or borrow one)

Set the dial indicator to measure the middle of the pad contact area and rotate the rotor 360*. Find the difference between the lowest and the highest readings.

11” rotors are permitted .004” max and 12” rotors are permitted .002” max run out.

If your rotor exceeds this run out tolerance it must be corrected.

The one piece rotor will have to be removed and machined true or replaced.

The hat type rotor can be trued by you in your drive way and usually just gets replaced if its too far out because they are cheaper to replace then machine and a machined rotor is not so desirable anyway as its mass is reduced making it have less braking potential.

Correcting run out on the hat type (type K) rotor. You will have to do this only once if done correctly. With the rotor held in place by five evenly torqued nuts. Using a Chalk, mark the rotor and a stud to index your starting point. Remove and install the rotor in all five different stud locations and re-measure at each location as describe above. Make sure the hub and rotor mating faces are clean and free of any bents or burrs that might cause the rotor to be held up. Record your findings in each position on a note pad. Once you have found the best fit, permanently mark the rotor and one stud tip with a paint mark to retain this indexed location should the rotor ever have to be removed.

If at this best fit location your rotor still exceeds the max run out tolerance you will have to purchase a shim (see above) of the closest amount to bring the rotor true.

Note: think about this: the shims come in correction factors of .003”, .006” and .009” run out. You have five different stud positions to choose from and the shim can be placed in five different positions as well. That means you now have twenty five different choices for best fit. If you look at the measurement notes you took during the check you can mathematically choose a shim and stud position combination to bring almost any rotor into near perfect running. If the run out exceeds .013” in the” best position” with no shim: either the rotor is too warped and a replacement is necessary or you have a hub and/or wheel bearing problem. A quick check using the other rotor as a test (because you have two)will tell you if it’s the rotor or the hub that is problematic.

On designing a brake system: I constantly hear from vanners, is there a “disc brake kit”? The short answer is No! so stop asking. The reasons are as follows. These vans are all different; no two are alike as you will see in the following text. I originally designed the M1D bracket and provided a list of optional calipers, brake hoses and installation options to try to accommodate the many variables that exist through out our vans. That didn’t work out so well because many people had no clue on what to choose or why to choose it. So I am designing three different disc brake brackets that work on “my van”. I will provide a parts list of a single rotor, caliper and hose for each to make it simple. You only have to choose which set up you want. One will use a one piece 11” rotor and be the easiest to install. This will be available in a manufactured bracket or as a template for the budget minded at home fabricator. The second will use an 11.16” hat type rotor, a little better system, a little cheaper then the former but more work to install. The third will be a 12” hat type rotor and even more cost and work to install. Additional to any of those will be “what are you planning for rear brakes” and “what is your van” and “are you planning power brakes” , do you “have a sway bar” that will lead into what you have to do about a master cylinder and proportioning and other valves.

If you would like to design a brake system specific to your van you need the following information.

Max GVWR

Static weight on the front axle

Static weight on the rear axle

Maximum deceleration rate expected (typically between 1.0 to 1.5g for sedan or sports cars, unit less)

Center of gravity height (go online to learn methods of determining using corner weight scales)

Wheelbase

Disc/disc, disc/drum?

Tire rolling diameter (you can use the tire diameter) of both front and rear if not the same.

Tire pressures

Coefficient of friction of the tires. “Traction rating”.

The size/area of each caliper piston and/or wheel cylinder.

Type of suspension used, springs and shocks.

% of weight transfer from one axle to the other during max braking. “Brake shift”

Rotor sizes and/or drum size

Pad and shoe surface area and coefficient of friction.

Target foot pressure

Pedal ratio

Boost multiplication product

Master cylinder piston area.

OK! That’s not the whole list but I will stop there, show me two of our vans that have the same values, or even the same tires!

This is one of the many reasons why there is no “kit”. Anybody who wants to upgrade their van brakes should educate themselves with some basic knowledge before getting into it. You don’t have to be an engineer but changing the brake system on your van is not an out of the box “bolt on thing”. That being said, many of those so called bolt on brake kits from popular after market name brand suppliers in most all cases require additional modifications to be installed and some need way more work then what it takes to do disc brakes on these vans.

Here are a few “get you started” links if you want to go the 9 yards on designing your brake system.

http://www.hotrodheaven.com/tech/brakes/

http://www.stoptech.com/tech_info/PedalSetup-DualMaster-Guide.pdf

http://www.engineeringinspiration.co.uk/brakecalcs.html

http://www.cheapsportscar.net/hydraulics.php

If you want disc brakes as simple as possible; the Nova rotor set up and a disc/drum configuration using the early corvette master cylinder, two residual valves and an adjustable proportioning valve. That’s as simple as it gets. You will have to do other changes according to your vans needs.

On proportioning and valves: (Sometimes called “Hold off valves” or “Metering blocks”}

Actual “Proportioning” is affected by many factors, in fact about everything on that above list affects brake proportioning. The proportioning valve is intended to bring correction to braking imbalance inherent in all vehicles. In order to make that happen correctly; factory proportion valves are very vehicle specific and sensitive to the needs of that vehicle it was designed for. Proportioning valves don’t actually reduce the “pressure” to the rear brakes, they slow the rate at which the rear brakes will get up to the same pressure as the front brakes. Some proportioning valves are simply a calibrated drilled hole that restricts flow rate and higher quality valves are a spring loaded plunger on a seat. Either way, they are made for a specific vehicle. The one size fits all proportioning valves sold by leading aftermarket suppliers are no better a choice then using a valve off any other vehicle. They might be reasonably close but chances of them being right is about as likely as winning the lottery. I recommend an adjustable proportioning valve for all brake system modifications to both 1st and 2nd gen vans. An added feature to an adjustable valve is you can change it to what you need; like an empty van vs. a fully loaded or towing a trailer in the mountains or tire size change.

On residual valves: Residual valves are necessary, the drum brakes need a 10 lb residual valve to keep the cylinder seals spread and the shoes ready to apply. The Disc brakes need a 2 lb valve to keep the pads ready to apply. These valves keep the fluid system partially pressurized which aids in a higher brake pedal. Another reason for residual valves is to keep the fluid from gravity feeding back to the master cylinder which is a particular problem when the master is near the same height as the wheels like on the early G. Only one residual valve is used per circuit (one for the front and one for the rear) They should be mounted right outside the master cylinder and before any other valves or “T”s.

You will know if you need one of these valves if you have to pump the pedal twice to get a good pedal.

On master cylinders: No matter what brakes your van has these guys have a master for it.

http://www.tuffstuffperformance.com/index.cfm/page/ptype=results/Category_ID=210/home_id=206/mode=cat/cat210.htm

There are several different master cylinders that could be used depending on what your van is and what braking performance you would like. To keep it simple, we like the early corvette master because it has a low profile that fits well in the stock van master location. (the 1st gen requires additional mods) and it has no internal residual valves.

Size: these masters are available in 1” bore and 1.125” bore. Let’s say your foot pushes 100lbs force, the 1” bore is easier to apply to full brakes but will travel further down. The 1.125” bore conversely will be harder to apply full brakes but will have a higher pedal. These days it is very likely you will get “low drag” calipers. These calipers sometimes need to have a “Quick take up master” which will give a higher brake pedal by design. To date there has not been enough experimentation with quick take up masters on our vans to recommend which to use. They are available for 1985 ½ ton trucks and Blazers and such in both 1” and 1.125”. Disc/drum masters usually have a built in 10lb residual check valve for the drum brakes and no valve for the disc side. I could assist any one willing to experiment with this type of master. Because of the design and ratio of the van brake pedal, the 1” feels like it travels too far and the 1.125” feels a bit too hard. One thing is for sure: we are talking manual disc brakes in a vehicle with an old school style brake pedal geometry. Drop all your expectations right now! Because disc brakes in you vintage van is not going to feel anything like your 2008 Chevy Malibu.

On power brake boosters; Conventional Brake boosters that go between the pedal and the master do not boost brake pressure. What they do is make the pedal easier to push. The boosters that have a separate cylinder attached and fit into the hydraulic system do boost pressure. Installing the conventional type booster in our vans requires re-locating the master cylinder to some other place and making a linkage to connect it to the pedal. This takes above average fabrication and design skills. I have done a power brake conversion on my 65. I had the original “Bendix Hydro-Vac” booster with the drum brakes on my 65 it was a dealer installed item and I have to say made the brakes dam near as good as my disc brakes. There is also Hydroboost driven off a PS pump and there is also electrically powered brake boosters.

Here is something you might consider:

The EC-1500 Hydraulic pressure multiplier from ECI.

On brake lines and hoses: It is best to use the smallest diameter and hardest lines possible. 3/16” steel seamless line is recommended for our vans. All lines and hoses more then ten years old should be replaced and fluid should be changed every two years to reduce internal corrosion and sludge build up in lines. Any steel brake lines more then 25 years old is plane suicidal. Change then all out for new. Brake lines can be stainless steel and galvanized steel, any other metal is not tough enough for the job. Stainless steel is much harder to flair and work with but much higher quality that does not corrode. The least amount of connections the better. The best flex hoses are the steel braided hose with a nylon internal tube because they resist swell under high braking pressure which aids in a better feeling pedal. Rubber flex hoses like the factory type are acceptable. Hoses must be DOT approved for road use. Flex hoses need to make bends yes, but they should be installed in such a way that they do not twist. They have a straight line painted on them to aid in proper installation. Twisted hoses will come loose as they try to untwist under pressure and also cause excessive pedal travel. You want the shortest line possible but it must be long enough to handle full suspension extension and full turns both ways simultaneously.

On front disc brake conversion:

Front disc brakes are probably the single best improvement that can be done to these vans, seconded only by the conversion of the 1st gen to a duel circuit brake system. There are several different front disc brake setups in use for these vans. All with proven degrees of successes and failures. Some take more additional van mods to install, some change the steering geometry more then others and some are simply harder to do then others. I have listed three such set ups at the end of this article. There is one after market supplier providing “a kit” as they call it which requires considerably more van modifications then any other bracket made for these vans, uses the smaller metric caliper and requires machining of some steering components and changes the steering geometry allot.

Converting the front axle to disc brakes will cost about $500 and up depending on what quality and grade of components you buy. You will then have to convert to a duel circuit master cylinder for disc brakes, add proportioning and residual check valves, do lines, hoses and fluid flush for another $250 or so. You might convert to rear discs for about another $500 or just spend $100 bringing you rear drum brakes up to service standard.

On rear disc brakes;

The first question would be why do you want them? 9” drum brakes are plenty braking for the back of these vans. 10.5” rotors are as large as you could ever use, anything larger will not get used enough and the rotors will always look rusty. Have a look at any car show, there are lots of rear disc vehicles with rusty rear rotors, those cars are not using their rear brakes enough which is dangerous and shame full. The axle flanges will have to be machined down to fit into the hat type rotor. Rear disc brakes present another low pedal potential and other maintenance headaches. They are particularly sensitive to the knock back caused by calipers unable to free-float enough because the axles move in and out quite a bit. The posi rear ends are said to be worse for this problem but that’s not my experience. I have found a good tight posi rear end to have less axle movement. If there is any hang up of the caliper on the bracket the axles will just push the piston into the caliper resulting in a very low pedal. There is also a particular installation and initial adjustment that must be done correctly at the time of bleeding brakes. Failure to follow said instructions will leave a piss/poor pedal feel. See link: http://www.classicperform.com/TechBook/BrakeBleed.htm

The rear calipers adjust off the parking brake. The parking brake is incorporated into the caliper piston. You must set the parking brake every time you park the van. The rear caliper pitons utilize a one way clutch inside the caliper piston. When the parking brake is applied the clutch senses when there is .030" or more clearance between the friction material and the rotor on the inboard side. When there is more than .030" the clutch turns inside the piston adjusting it out keeping the rear brakes adjusted. If you do not set your parking brake every time you will start to lose brake pedal (low and spongy) and the adjuster mechanism will not work any longer. Also: never use rebuilt calipers on the rear because the re-builders use the old pistons and the pistons were the reason the caliper failed in the first place.

On calipers: There are basically two calipers that are used when modifying vehicles the weight of our vans. The most common to use on the front is the standard 7” mount caliper, it has an almost 3” piston and uses the # 728 pads. These are used by GM on most ½ ton and ¾ ton PU trucks, vans and cars of the same weight class. They come in a variety of different part numbers and that is a reflection of the many different hose attachment and bleed screw configurations they can be had in.

On the rear disc brakes a smaller caliper known as the “metric” caliper uses the # 7070 pad. Ironically it is not actually smaller on the outside. This metric caliper comes with a variety of piston sizes and should be selected according to “proportioning” needs. The metric caliper comes with a built in park brake mechanism for rear use or without as a plane caliper when used on the front of lighter vehicles. Sometimes these smaller calipers are used on the front of heavier vehicles like our vans and that can be made to work if the master cylinder bore size is matched up to use this smaller piston caliper. Braking effectiveness can be the same under normal braking but because of the smaller pad surface area these metric calipers are likely to eat up pads when used on heavier then intended vehicles and will likely heat soak and crystallize under very heavy braking conditions while on a vehicles of 4700 GVWR or higher. The one advantage to using these metric calipers is that they are somewhat lighter then the standard 7” mount caliper.

On Brake fluid:

D.O.T. 3 brake fluid is the longest running proven fluid for your street van. This fluid is recommended to be flush changed every two years. A can of DOT 3 that has had the lid off it for a day is garbage, especially if in a humid environment. This is because this fluid is hydroscopic (sucks moister out of the air). When DOT 3 fluid achieves 3% moisture by volume it is unsafe to use. DOT 3 is cheep, has anti aeration properties, modern DOT 3 has corrosion inhibiters and is designed for your street van. In the old days, used DOT 3 fluid was boiled on the stove top to remove moisture then filtered and re-used because it was expensive and hard to get in some places, they still do that in some places today.

There is lots of talk about synthetics, DOT 7 and alike. There is a lot of people talking but most are just lip flapping what some sales brochure says, few actually know!

I have information from the brake engineer who designs and maintains the $45.000 brake system on a friends formula race car.

These often called “High performance” brake fluids have pros and cons. They are a different fluid with different qualities designed for different applications. The primary advantage for these synthetic fluids are their intended temperature range. Your brake rotors are not going to be glowing at 2300* for four hours while you run your van in the Daytona 500.

The down side to these synthetic brake fluids made for high temp use is that they are “Not” hydroscopic, meaning they do not absorb moisture. This means the regular condensation accumulation and moisture ingestion that happens in brake systems with normal street driving will accumulate in the calipers and cylinders as water droplets or as an emulsion. During highway braking these water droplets can boil and turn into steam bubbles and your pedal suddenly gets spongy or goes to the floor and you loose about 90% of your braking ability. After your accident your insurance broker and the police claim you are a reckless driver because when they try the pedal, the steam has cooled down and returned to water drops and your pedal feels fine to them.

Because of this problem, manufacturers state! if you run synthetic brake fluid in your street vehicle it is recommended the complete system be flushed with new fluid every three months.

Another fact about synthetic fluid is, it is some what compressible and always makes for a spongier pedal compared to DOT 3.

Synthetic fluid is also subject to aeration and so bleeding has to handled with greater care.

D.O.T. 3 brake fluid is designed for what we do, using other fluids will not improve your vans braking performance.

On brake pads: There are several different types of brake pads available for most any caliper. Primarily the difference is the “coefficient of friction” the pad material has when at its design operating temperatures. One other difference is some of the cheaper pads are on thinner backing plates which may flex under compression adding to a spongy pedal feel.

Brake pads made for racing and “High performance applications” do their best grabbing at temperatures higher then your van brakes will ever get. These pads will have poor braking effectiveness at normal street driving temperatures. You want a good quality but standard semi organic every day bone stock brake pads for your van, they are designed to grab best at lower brake temperatures like your van will be doing in 99% of its braking life.

I hesitate to say cheaper pads are best only because you also want a strong steel back plate on the pad. So middle priced regular replacement pads are what will work best on our vans.

If you really want an upgrade in pads try the factory police and service vehicle pad. Available to replace the # 728 pad these # 7506M pads have a larger stronger steel backing plate and have about 20% more pad contact area. They should fit right into the BZ bracket, and the M1DK10N bracket and will fit the bent M1D bracket with a minor grinding to the lower corners of the inside pad. See photos below.

Look how they compare to the standard brake pad on the left.

With minor clearance grinding they will fit onto the original M1D bracket and the newer M1D80TA bracket. They need to clear at the bend line of the bracket so the inner pad will sit flat and may need the inner most corners ground away a bit to permit a parallel seating.

On parking brakes: Once upon a time these cable powered brakes were called emergency brakes because that was a time in history when the tried and trusted cable brakes were being replaced with the very unreliable “New” hydraulic brakes. They were kept on because that’s all you had to stop with once your single line brake system developed a leak and failed. Today these are called parking brakes because they hold OK and resist forward movement of the static vehicle when parked (drum brakes). Caliper park brakes hold the same in either forward or reverse direction. If you ever tried pulling on your park brake while going down the high way you will discover why realistic auto designers do not call them emergency brakes. Parking brakes on most all vehicles also double as a brake adjuster and therefore should or must be used every time you park the vehicle. Our vans have a rather primitive pulley and cable system for the park brake with a not so friendly to use handle. The virtue of this primitiveness is replacement cable can by fabricated up as easily as installing a clothes line. Many persons customize there park brake to newer style cables and handles. If you go to rear disc brakes you will have to modify your park brake system to something effective. I used the Corvair dash mount handle and mounted it on the floor of my van with modern type cables. It works easy and well. Two things I like about this handle positioned where I have it, is the handle hits the back of my leg disrupting my foot from being on the gas pedal comfortably when the brake is on, and, this brake handle is way easier on my back to engage.

Hope this comes as helpfull.

Thank you

M1d