+3

Twinpilot001

donivan65

Farmer

7 posters

Balancer/pulley problem

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°1

Balancer/pulley problem

Balancer/pulley problem

I have a 65 G10 with the stock 230 six cyl. I noticed a rattling/clunking noise when I would shut the engine off. I found the balancer was loose. I was able to wiggle the balancer off after loosing the alt belt. Is there suppose to be a bolt and washer holding on the balancer or is a pressed on fit? My balancer is shot...the keyway is enlarged and also where the front cover seal rides there is a groove worn in it. Does anyone have a good pull off they could part with OR a source for a new one? My local GM dealers are useless. I love this site and visit daily.

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°2

Re: Balancer/pulley problem

Re: Balancer/pulley problem

The BIG question is,,,,,,,,how does the crankshaft look? Can you take a measurement on it to see if it is worn out? Those pulleys are pressed on,,,,,,,,do you have a wrecking yard near by to pull a 6 cylinder pulley off of or an engine shop might have one,,,,,,,,,,

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°3

Balancer/Pulley

Balancer/Pulley

Thanks for the reply Donivan. The crank was my biggest worry when I realized what was making the noise. I've had a Dodge 360 with a loose balancer that snapped the crank at the first lobe going north to see the folks in Wi. Happened in around your old neck of the woods..Worth, Il. What a crappy X-mas that was. Anyways, I believe the majority of the damage was done to the balancer (by the way, is it really a balancer or are these 6 cyl's internally balanced?). The key way on the crank is not damaged. I don't have a dial indicator or any of the other tool to properly check it. It APPEARS to be ok, no gouges, no ridge worn in it, no lip at the front. Maybe I got lucky? Do you have a suggestion on how to test it? I was hoping to find a new balancer and test fit it before I do something drastic, like pull the motor. I'm going to start the JY calling tomorrow, hopefully I can find one. Again, thanks for the help.

Twinpilot001- Number of posts : 6186

Location : spokane ,Wa.

Registration date : 2009-09-28

- Post n°4

Re: Balancer/pulley problem

Re: Balancer/pulley problem

heres one 4 ya= I know on chev engines - there was a fix for the worn balancers. Seems like a sleve was available to press into the balancer?/ Going back from my old =really old memory. Is suggest asking someone with napa - thats been around a while?? Happy hunting

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°5

Re: Balancer/pulley problem

Re: Balancer/pulley problem

That Napa repair sleeve is for sliding over the groove that the seal cuts into the balancer,,,,,,and you might need one if you find another balancer that has a groove in it. The pulley is 1.240, so the crank should be around 1.245,,,,, so you really need to try another balancer on it and see if needs to be beat on to stay on to determine IF you need to buy another engine,,,,,,,

panelmanrd- Number of posts : 801

Location : kcmo

Age : 63

Registration date : 2009-10-04

- Post n°6

Re: Balancer/pulley problem

Re: Balancer/pulley problem

the press on sleeve is used to repair the seal surface on the

ballancer. I have installed quite a few of them. no real patch

for the loose ballance on the crankshaft short of replacing the

crank and the ballancer. old worn part will wear the new part.

there is a designed press fit between these two parts that has

to be there for it to work. sorry guys no quick fix here without

an enormous amount of luck.

ballancer. I have installed quite a few of them. no real patch

for the loose ballance on the crankshaft short of replacing the

crank and the ballancer. old worn part will wear the new part.

there is a designed press fit between these two parts that has

to be there for it to work. sorry guys no quick fix here without

an enormous amount of luck.

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°7

Re: Balancer/pulley problem

Re: Balancer/pulley problem

I believe I have found a balancer from a friend. This guy has four Corvans so I didn't think to ask if he had a straight six laying around. He has a complete 230 engine out of a 65 3/4 ton p/u that ran when they pulled it out yrs ago. I climbed through a junk filled bread trk to find it. From what I could see it has a triple groove crank pulley, a single bolted to a double groove balancer/pulley. My question: will there be any problem going from a balancer with a single groove pulley to a double groove pulley? Maybe lady luck will be with me on this one.

panelmanrd- Number of posts : 801

Location : kcmo

Age : 63

Registration date : 2009-10-04

- Post n°8

Re: Balancer/pulley problem

Re: Balancer/pulley problem

no problem with the swap at all.

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°9

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Check to see if the timing mark line is in the same location,,,,,,,,and you might have to shim the fan out away from the waterpump if it rubs on that double belt pulley,,,,,,,,,,,,,,,,

panelmanrd- Number of posts : 801

Location : kcmo

Age : 63

Registration date : 2009-10-04

- Post n°10

Re: Balancer/pulley problem

Re: Balancer/pulley problem

good idea, i didn`t even thing about that.

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°11

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Thanks for the help guys, I'll let you know what a find.

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°12

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Done deal. The pull off balancer was in great shape, no issues with where the seal rides. Donivan, thanks for the tip about the timing notch, it was off by about two inches. I cut a new a new one with a hack saw blade and painted it white. All back together, no leaks (new seal),no vibrations, purring like a kitten. Life is good!

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°13

Re: Balancer/pulley problem

Re: Balancer/pulley problem

The pulley and mark on those balancers are rubber mounted so the mark can slip,,,,,,,,,,and EITHER one of those marks could be lying to you,,,,,,so you don't know where the timing actually is. I think if the key in the crankshaft is at the 12 o clock position, the notch should be at the 1 o clock position. Does your new mark show up around 4 degrees Before Top Dead Center when you shine the timing light on it or the other one or none at all?

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°14

Re: Balancer/pulley problem

Re: Balancer/pulley problem

The original pulley the notch was between the one and two o'clock position as you would look at it, about 2 1/4" from the key way. The replacement pulley had the notch directly in line with the key way. When I put the timing light on it with the vacuum advance unplugged, the "new" white timing notch showed up on the topside of the timing tab. I went to move the dist and found it loose. I turned it so the notch was in the middle of the timing tab and the engine rpms came down and it seemed to run better. The original notch is somewhere under the waterpump pulley.<<<<Does any of this make sense??

Now, I have a question concerning the timing. On the timing tab it has

| | O | | | | A | | what is the proper procedure for setting the timing? RPM's?, vacuum unplugged, and where on the timing tab?

Your help is appreciated!!!

Now, I have a question concerning the timing. On the timing tab it has

| | O | | | | A | | what is the proper procedure for setting the timing? RPM's?, vacuum unplugged, and where on the timing tab?

Your help is appreciated!!!

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°15

Re: Balancer/pulley problem

Re: Balancer/pulley problem

1st thing is make sure the points are adjusted,,,,then unplug the vacuum advance and set RPM around 600. You want the timing around 6 degrees Before Top dead Center,,,,,so the 0 is top dead center and you want the mark 3 lines ABOVE it. Then, since you filed a new mark on the pulley, turn the distributer a little each way,,,,,,see where the engine is happiest,,,,,,and see if your mark shows up 3 lines above the 0. The old mark should be under the waterpump,,,,another way is set the timing so you get the highest vacuum reading if you put a gauge on it. Check the centrifugal advance by speeding up the engine and seeing if your timing mark trys hiding under the waterpump,,,,,,,plugging in the vacuum advance should make the timing mark hide even further under the waterpump than the centrifugal does. Then adjust the carb mixture for the highest RPM,,,,,,if it goes over 600, crank the RPM down until you got the mixture set for the highest RPM which is around 600,,,,,,,,

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°16

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Excellent information Donivan! I am very grateful! After tweaking on the carb and timing, the engine feels to run the best around the 8 degree mark, centrifugal and vacuum advance are both working. So, apparently there are different balancers out there for the 6 cyl's. When I bought this van it came with a brand new elec dist, plugs and plug wires not installed. Makes me wonder if someone before me found this problem and didn't want to deal with it. Next I'll tackle installing the new dist, once I figure out the wiring. Thanks again Donivan!!!

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°17

Re: Balancer/pulley problem

Re: Balancer/pulley problem

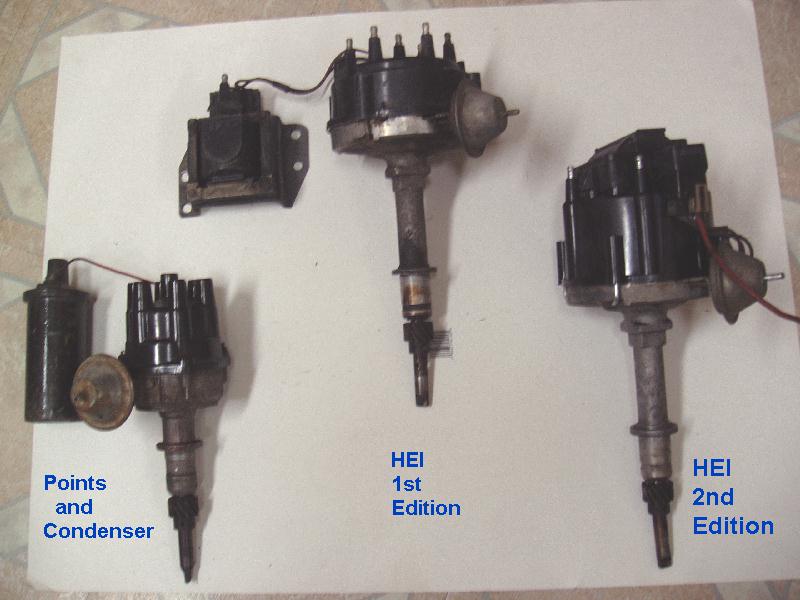

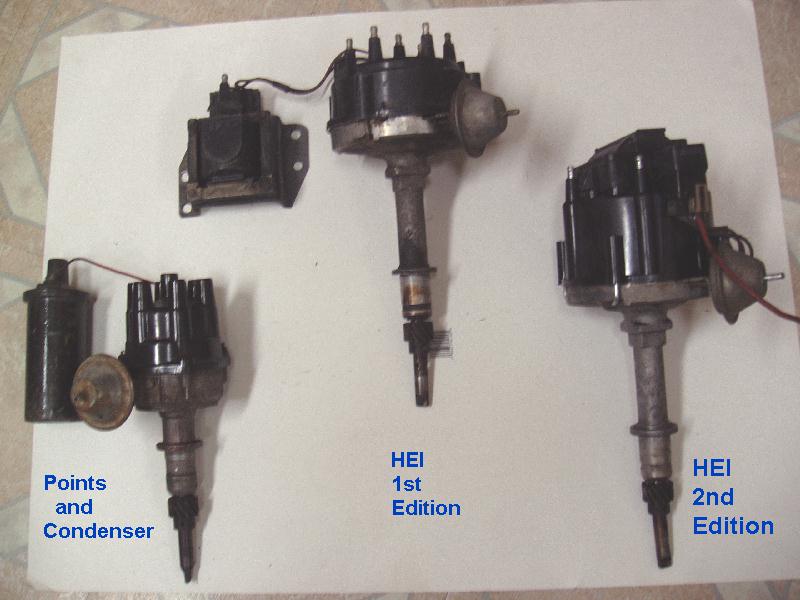

I would paint a line across the 2 sections of the pulley on the front over the rubber section and check it once in a while to see if the pulley is slipping,,,,,,,,,or that balancer could of come from a P-10 step van,,,,,,,,their 6 cylinder engines time on #2 cylinder. So make sure those points are adjusted if you still are running them,,,,,,every .001 change in the points changes the timing 1 degree,,,,,,,so as the points wear, the timing retards accordingly. So the newer HEI distributors fit right in and need only 1 wire to make it work,,,,,,,,,do you have that or some other brand of electronic distributor to put in?

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°18

Re: Balancer/pulley problem

Re: Balancer/pulley problem

I have the HEI with the coil on the top of it, big ugly thing with a black cap. It looks like the one they sell on ebay. The wiring harness has a tan wire that goes to the coil and a green wire that is snipped off in the harness. On the other side of the coil is the dist wire and the wire for my tach. I've been wondering what the green wire is/was for. I understand points need 12v to crank and 8v to run and elec dist like the 12v constant. I need to get the fluke meter on these wires and see what's going on with them.

savage- Number of posts : 2632

Location : Where Rust Never Sleeps in Ft Wayne IN

Registration date : 2008-05-15

- Post n°19

Re: Balancer/pulley problem

Re: Balancer/pulley problem

The Green wire is probably the water temp sender wire??

Twinpilot001- Number of posts : 6186

Location : spokane ,Wa.

Registration date : 2009-09-28

- Post n°20

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Hello =all= as Im from the old schoo;= i have never liked the HEI distributors- The point type =even when needing new points -can be cleaned enough to get running or down the road to the parts house. Tha HEI - when its dead- well just dead!!= I will add i have installed a electronic points eliminator kit in a older points type distributor that is still working perfectly after 40 years in the car. I sell or give away every HEI , i ever get-just dont like the bulky look & having to test the components when dead. just My Thoughts. Happy Vanning!

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°21

Re: Balancer/pulley problem

Re: Balancer/pulley problem

So are you talking about the vans wiring harness?

It could be all changed over the years, but the ballast resistance wire should go to the R terminal on the starter solenoid and then another wire goes from there to the Positive side of the coil. The HEI needs more power to run,,,,,,,so you normally run a 10 or 12 gauge wire to it. And you can find 12 volts for it, at that pink wire, going INTO in the connector by the carb.

It could be all changed over the years, but the ballast resistance wire should go to the R terminal on the starter solenoid and then another wire goes from there to the Positive side of the coil. The HEI needs more power to run,,,,,,,so you normally run a 10 or 12 gauge wire to it. And you can find 12 volts for it, at that pink wire, going INTO in the connector by the carb.

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°22

Re: Balancer/pulley problem

Re: Balancer/pulley problem

My van harness seems to be original by the shape it's in and how crusty the tape surrounding it is. I have the 2nd edition (just like you have pictured) hei dist to install. With the engine running I have 8.4 volts at the positive side of the coil. I found the green wire to have 10.4v while running and 0v with key off. Without taking the harness apart, it appears this wire goes into the voltage regulator. I don't need it for anything, just wondering what it's purpose is/was? I found the 12ga pink (red) wire in the large connector at the carb, I'll tap into that for the hei dist.

Digz- Number of posts : 3794

Location : United States Six Lakes MI

Registration date : 2008-05-17

- Post n°23

Re: Balancer/pulley problem

Re: Balancer/pulley problem

Maybe Im wrong ,but I think that big pink/red is your main feed to the dash, that might make your distributor hot all the time ? Ideally the HEI should be on a 10 amp fused circuit if Im remembering correctly and only hot with the key in the On position. Someone else is going to have to chime in here becasue Im wired a bit differently than most.

donivan65- Governor

- Number of posts : 12245

Location : San Diego, California

Registration date : 2008-05-12

- Post n°24

Re: Balancer/pulley problem

Re: Balancer/pulley problem

If that wire is around the dipstick, it could be the dark blue wire for the oil sending unit,,,,,,,,does your oil light work? and check the Pink wire coming INTO the connector,,,,,,when it comes out of that connector it turns into that white/orang/purple resistance wire. And like Digz said, you really should run a bigger gauge wire to the ignition switch to do the job right,,,,, ,,,,,,,you should install a fusible link in the feed line to the fuse box and ignition switch.

Farmer- Number of posts : 67

Location : Randolph, Tn

Registration date : 2010-12-27

- Post n°25

Re: Balancer/pulley problem

Re: Balancer/pulley problem

The only lite I've seen come on is the Gen lite. There is no oil sending unit. It was replaced with an oil line going to a gauge in the dash. I guess instead of splicing the van harness any more than it has been, I'll plan on running a 10ga fused wire direct to the dist. Sounds like a project for this weekend, weather permitting. Thanks for the help guys! I'll let you know if I need help.