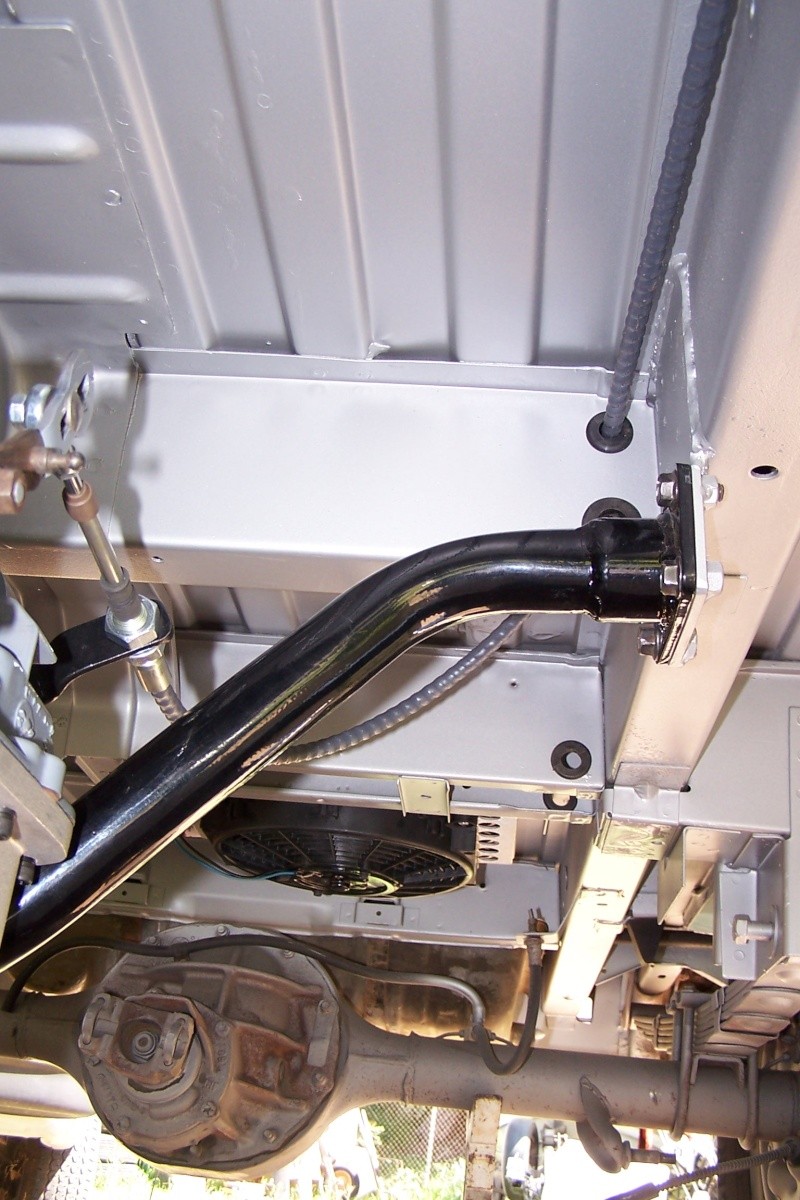

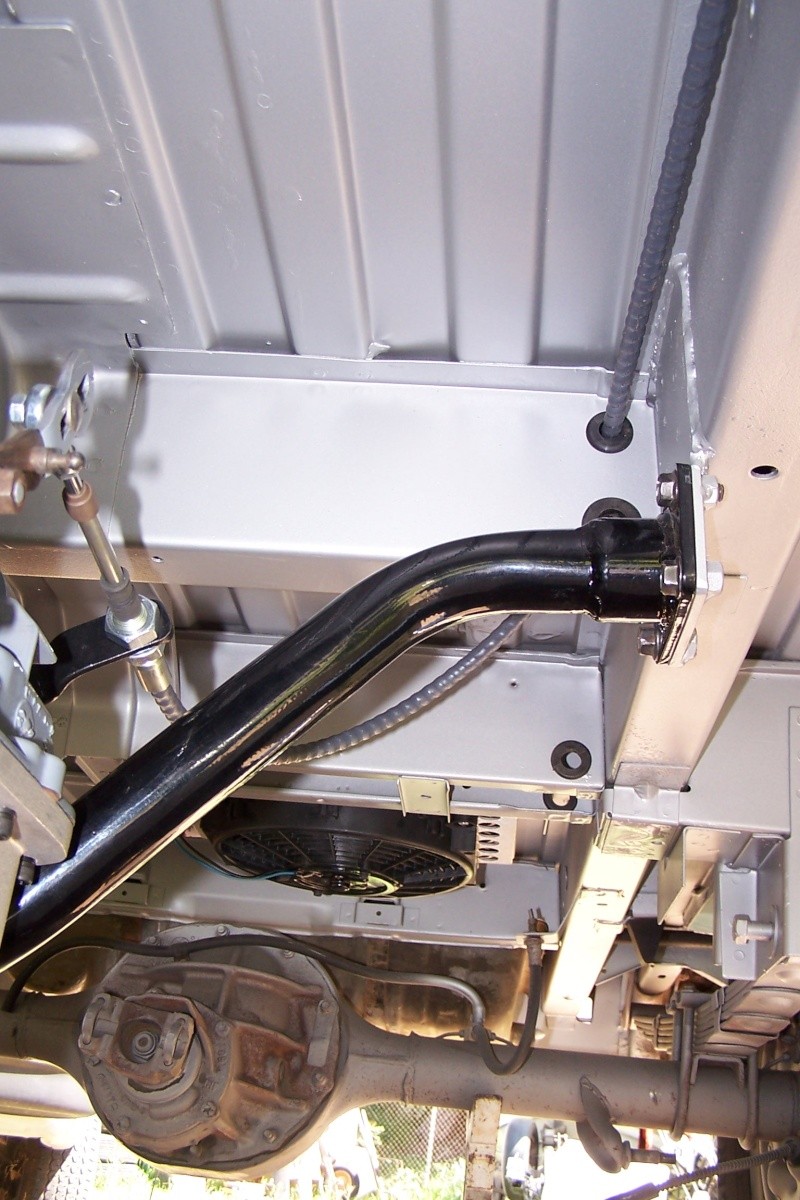

Here is a picture of a Taurus fan I first posted for everyone about 5 or 6 years ago. This one was a custom 4 row aluminum radiator that copied the 240 size for a built x flow aluminum head 250. The idea being that the Taurus fan hard to beat for $18 bucks. Rumored CFM at 4200. When I first found the link and info I didn't realize an issue that could creep up to do with the alternator.

On my V8 conversions I have the stock 3 row 240 radiator bumped up to a 4 row,, I have four of them now done and the cost usually about $350. One replacing the smaller Champion aluminum four row with their factory fan and shroud which does not blow much air and not as good as the Taurus fan.

The Taurus fan has a HIGH AMP load when running but even more of a HIGH AMP load on start and it will blow fuses if not wired up correctly for it. I also posted using a VOLVO dual relay setup for high and low speeds that you can buy at the yards for about $10 bucks also. The Volvo fan is about 18" in diameter and fits ours perfectly also?? Have not used one YET,,, but it wants to fly like a helicopter if it was a little lighter in weight,,, LOL.... Plans are to try one here some day and have a shroud made for it,,,,

Back to the Taurus fan. About 20 years ago, I came up with a remote fan cooled transmission cooler and is now pretty much a standard feature on our late model trucks,,, IT WORKS,,,, the point here that I have been talking about forever is that our doghouse is nothing more than a BIG OVEN and what ever heat load you can take off of the radiator exchange load is a plus. So,, WHY add the heat from the torque converter slipping in stop and go traffic to the doghouse heat??

I also don't run the belly pan as IMO its a band aid and does exactly nothing in stop and go traffic when its so hot you could cook eggs on the roof of your van!!!!

My point here is that our alternator was and is NOT designed for the loads that we now put on our trucks,, amps, stereos, electric fans, so on, so on,, etc. Even a high output 60 AMP alternator or even the famous one wire 100 AMP Delco alternators do not put out their posted maximums at idle!!! They have to run at 1500 rpm,,,, My question being it makes no sense to be stuck in traffic, with the heater running to help get rid of heat, an electric fan for the radiator and my foot on the gas pedal keeping the RPM up in order for the fans to run at their full CFM ratings?????? and then adding more heat because of my foot on the gas pedal,,,, duh,,,,,

SO,, I use the 3G alternator as it puts out 90 amps at 600 rpm,,,,, The Taurus fan will eat some juice,, and the reason why I use this alternator.

A SIDE BENEFIT,, is that it has a piggy back regulator on it and you can ditch our regulator in front of the radiator. In regards to fan to water pump shaft clearance, that is very easy even with my four row copper raditators.. I use a piece of aluminum channel. The reason for channel is that I can mount bolts on each flange and not squash it by using one bolt all the way through it. Its easy. Mount it to the stock mounting bracket and move the radiator all the way forward.. In regards to wiring the fans,, I ALWAYS wire the relays HOT ALL THE TIME and have been doing it for over 15 years. IF your batteries are good and your charging rate keeping up with your usage, it will NOT drain your battery after you shut the motor off... it has NEVER happened to me. Ask yourself how many cars do you hear the fan running with no one in the car??? Its a common setup.

The idea is that the doghouse is an oven, and with no air circulation after you shut the truck off, the gasoline in the carb has nothing to do but cook!!! So, the reason why I wire it hot all the time. Its a good thing to hear my transmission cooler fan and the radiator fan running when I leave the truck, and then when I come back they are both off. Wired hot with the thermostat so that it shuts off when cooled down. Yes, I have heard the point about no fluid movement after shut down also, but heat transfers, and at least with the radiator fan running it is moving some air in the doghouse after you shut the motor off.

In regards to a V8 and fan clearance,, I gave up on using the long shaft water pumps a gazillion years ago,, LOL,,, and use the Motorsport standard rotation short nosed water pump just for a ton of room. If you bump up your standard three core 240 radiator up to a 4 row and move it forward you will still clear the water pump shaft,, AND if you use the 3G alternator its even better with no more voltage regulator trapped in front of the radiator anymore...

Here are few pictures,,, LOL,,, its hot and late for working on orders,, gotta run...

Vic