+8

EconoUSAparts

Digz

Magic Bus

rhysaccess

Bluelemon

RodStRace

sasktrini

donivan65

12 posters

king pins of the under carriage world...

EconoUSAparts- Number of posts : 2198

Location : Ft Thomas,Ky

Registration date : 2008-05-17

There have been many many posts about king pins at the OldEconolines site. Blue Lemon,aka Jim Bulger of Ga. site member there and here, did a set recently and should be able to comment on this soon. It sounds to me like the king pins you have may be a bad set. Theres a known problem with the locking groove depth on TRW king pin sets and other makes,possibly the set you have too. Did you use a reamer tool? Did you inspect the axle hoes for oval shape instead of round? I ll shoot Jim an email and have him chime in.

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

Did you try the kingpin shafts in the axle,,,,did they slip in real easy? They need to fit in there kind of tight for that pin to work,,,,,,,

rhysaccess- Number of posts : 103

Location : Western Australia

Registration date : 2010-02-07

I actually have two Federal Mogul king pin sets (ordering mistake) - and both are identical.

The king pins are a nice fit in the bushes - though only light tapping was required to install the king pins. I had the bushes installed and reamed out by a reputable performance machine shop. (I appreciate that that is no guarantee of course)

If consensus is that ANY movement of the king pin within the housing on the I beam is a bad thing....then I'm going to have to modify the locking pins to -

1) go in till flush

2) press tighter against the king pin to supress ANY movement.

Any ideas from Jim Bulger would of course be welcome.

Regards,

Rhys

The king pins are a nice fit in the bushes - though only light tapping was required to install the king pins. I had the bushes installed and reamed out by a reputable performance machine shop. (I appreciate that that is no guarantee of course)

If consensus is that ANY movement of the king pin within the housing on the I beam is a bad thing....then I'm going to have to modify the locking pins to -

1) go in till flush

2) press tighter against the king pin to supress ANY movement.

Any ideas from Jim Bulger would of course be welcome.

Regards,

Rhys

Magic Bus- Number of posts : 1422

Location : -Gateway to the West - St Louis Missouri

Registration date : 2009-12-02

Rhys,

I just replaced my bushings on my 67. My axle (you called it the beam) was worn . The pins fit sloppy and I had to send it to a machine shop and have a sleeve installed to make the pin fit tight. But what you are saying is that the pin rotates? There can not be rotation of the pin in the housing. When the locking pin is driven into place the kingpin should be very tight into the axle (beam). No movement should be happening as you stated that when you turn it you can see it move. Somethings wierd about the kinpins fitting and locking into your axle...Did you check the fitment of the kinpin in the axle by itself? Try installing the pin into the axle and see if it is snug, there should really be no movement even without the locking pin installed. I just did a search on federal mogul. They are apparently affiliated with TRW. Ive heard from others that know and have had experience with TRW kinpins on the econoline. They say they are a bad fit and won't work right, something about the locking pin groove not being machined properly and letting the kinpin move in the axle housing.

I used Moog. I also heard that the brand that Mac's sells works well. Keep us posted..

I just replaced my bushings on my 67. My axle (you called it the beam) was worn . The pins fit sloppy and I had to send it to a machine shop and have a sleeve installed to make the pin fit tight. But what you are saying is that the pin rotates? There can not be rotation of the pin in the housing. When the locking pin is driven into place the kingpin should be very tight into the axle (beam). No movement should be happening as you stated that when you turn it you can see it move. Somethings wierd about the kinpins fitting and locking into your axle...Did you check the fitment of the kinpin in the axle by itself? Try installing the pin into the axle and see if it is snug, there should really be no movement even without the locking pin installed. I just did a search on federal mogul. They are apparently affiliated with TRW. Ive heard from others that know and have had experience with TRW kinpins on the econoline. They say they are a bad fit and won't work right, something about the locking pin groove not being machined properly and letting the kinpin move in the axle housing.

I used Moog. I also heard that the brand that Mac's sells works well. Keep us posted..

Bluelemon- Number of posts : 139

Location : Atlanta, GA

Registration date : 2008-07-10

rhysaccess wrote:I actually have two Federal Mogul king pin sets (ordering mistake) - and both are identical.

The king pins are a nice fit in the bushes - though only light tapping was required to install the king pins. I had the bushes installed and reamed out by a reputable performance machine shop. (I appreciate that that is no guarantee of course)

If consensus is that ANY movement of the king pin within the housing on the I beam is a bad thing....then I'm going to have to modify the locking pins to -

1) go in till flush

2) press tighter against the king pin to supress ANY movement.

Any ideas from Jim Bulger would of course be welcome.

Regards,

Rhys

Hey Guys,

Tried to post last night, but my internet connection was lost till this morning.

You are correct that there should be NO movement of the pin in the axle. This will destroy the axle in no time.

TRW has been the bad pins with the locking groove cut too deep.

Do you have the original pin you removed and the new pin to be installed ? Compare the locking groove; should be the same.

Have heard of some installers inverting the pins and having the correct shallow groove cut in the other side to avoid buying another set/brand.

When the pin is in the axle, the groove for the lock should slightly be visible in the locking hole. Drive the lock in with a BFH till it bottoms out. Again, the pin should NOT move in th3e axle.

Bluelemon- Number of posts : 139

Location : Atlanta, GA

Registration date : 2008-07-10

Magic Bus wrote:Rhys,

I just replaced my bushings on my 67. My axle (you called it the beam) was worn . The pins fit sloppy and I had to send it to a machine shop and have a sleeve installed to make the pin fit tight. But what you are saying is that the pin rotates? There can not be rotation of the pin in the housing. When the locking pin is driven into place the kingpin should be very tight into the axle (beam). No movement should be happening as you stated that when you turn it you can see it move. Somethings wierd about the kinpins fitting and locking into your axle...Did you check the fitment of the kinpin in the axle by itself? Try installing the pin into the axle and see if it is snug, there should really be no movement even without the locking pin installed. I just did a search on federal mogul. They are apparently affiliated with TRW. Ive heard from others that know and have had experience with TRW kinpins on the econoline. They say they are a bad fit and won't work right, something about the locking pin groove not being machined properly and letting the kinpin move in the axle housing.

McQuay Norris is good. Haven't heard anything bad about Carpenter or Mac's.

Compare depth of locking groove in old and new pin.......TRW will be waaaay to deep !

I used Moog. I also heard that the brand that Mac's sells works well. Keep us posted..

Bluelemon- Number of posts : 139

Location : Atlanta, GA

Registration date : 2008-07-10

Don't know if my reply went thru.

Check depth of the locking grove in the old and new pin. The BAD TRW's will have the groove cut too deep.

The pin locked into the axle shouldNEVER moove.

Check depth of the locking grove in the old and new pin. The BAD TRW's will have the groove cut too deep.

The pin locked into the axle shouldNEVER moove.

Bluelemon- Number of posts : 139

Location : Atlanta, GA

Registration date : 2008-07-10

rhysaccess wrote:Hi all,

I've stripped and replaced the king pin bushes (and shimmed any remaining play).

Having some difficulty knocking the pins in that secure the shaft in place. Seems that they don't want to go the last 1/2" to sit flush.

Anyone else had this problem.........am I worrying about nothing?

Regards,

Rhys

Rys,

From the pictures, you have a 61-63 axle. 64-67 the pin is shorter and there is a threaded cap on top/bottom for grease.The rubber donuts seals are supposed to be as pictured. Should be same on top and bottom.

When you install new bushings in the spindle hub, be sure to orient the holes ( especially in 61-63 ) so the grease will enter. 61-63 has an 'arrow' , 64-67 has a 'ring' on the inner end of the bushing.

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

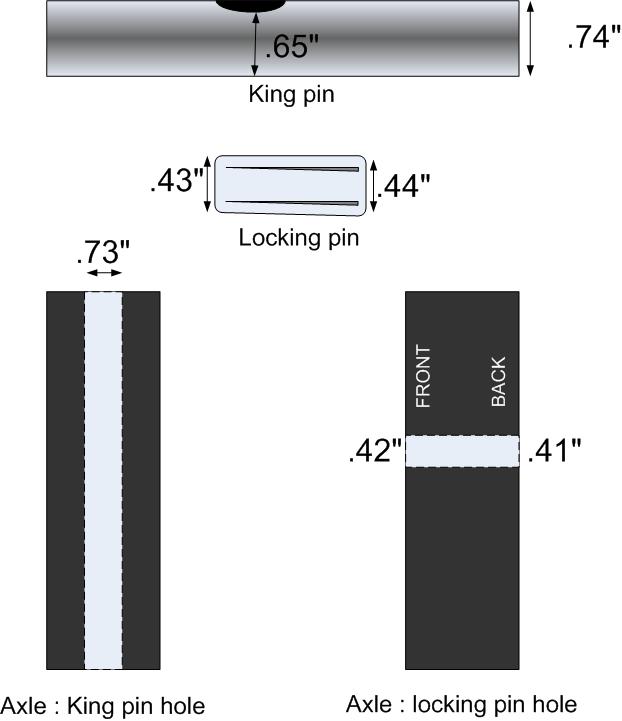

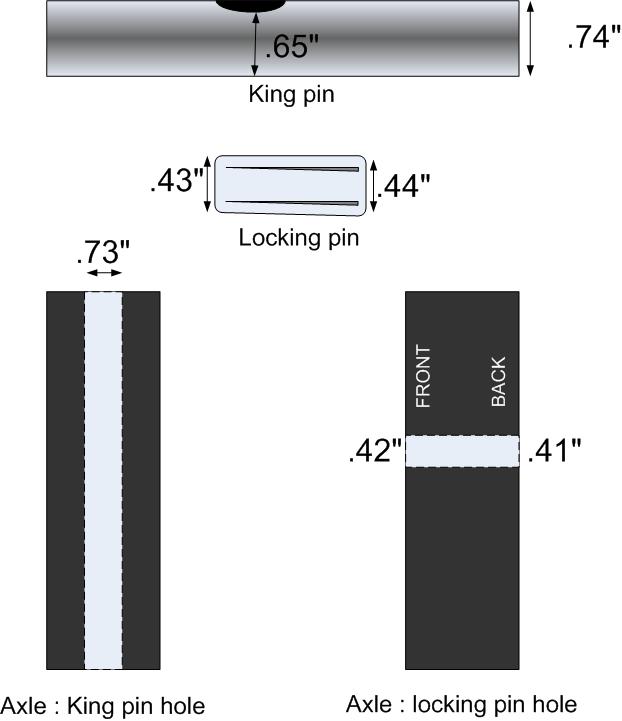

So tell me about this locking pin,,,,,,,,,it just looks like they hit it with a chisel to expand one end rather than make it tapered,,,,,,so is there a real big difference in the diameters on the Big and the SMALL ends? And which way is it supposed to go in,,,,,,hit it in from the back or from the front of the van? And taking it out,,,,,will it come out either way or do you have to hit it out from the small end? And how would you even know which was the small end just by looking at it?

Magic Bus- Number of posts : 1422

Location : -Gateway to the West - St Louis Missouri

Registration date : 2009-12-02

From just intalling mine... Mine were previously installed from the rear. The pin is slightly tapered, if you try to put it in backwards it will not start in the hole. You have to drive it out from the small end. The other end typically will swell up or mushroom, from driving in with the hammer, when installed and will NOT go any further into the hole, therefore you can't remove it by driving the big mushroomed end into the hold, it simply won't go.

As a side note, I drilled my old locking pins out. They were ridicously tight and would not budge, but the drill took care of that.

As a side note, I drilled my old locking pins out. They were ridicously tight and would not budge, but the drill took care of that.

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

I guess that is one answer,,,,,,find the beat up end and push the pin out from the opposite end,,,,,,but I think there are more pins pressed in gently or never been touched so you cant tell which way they come out,,,,,,,and once you start pounding or pushing, you just get 1 shot,,,,,if it don't move, it becomes flared out and you have to drill it out. So I guess there are no rules on which way the pin goes in and how to find the small end,,,,,,,,

rhysaccess- Number of posts : 103

Location : Western Australia

Registration date : 2010-02-07

Firstly I'd like to thank everyone for their generous input & ideas - as was identified earlier I'm some distance from the nearest econoline (they were never imported locally).

The installation has already been done....I'm just reviwing the results to see what has to be modified or improved.

The pins are subtley tapered, as are the holes they fit into. A quick comparason of end to end helps identify the disparity of both.

I have driven the pins in, from the front - to the back.

The king pins appear the same (with respect to the locating groove) between the old - to the new.

Good tip on the bush orientation....I'll dismantle and check. Seems I'll have to recheck everything.

Thanks again

Rhys

The installation has already been done....I'm just reviwing the results to see what has to be modified or improved.

The pins are subtley tapered, as are the holes they fit into. A quick comparason of end to end helps identify the disparity of both.

I have driven the pins in, from the front - to the back.

The king pins appear the same (with respect to the locating groove) between the old - to the new.

Good tip on the bush orientation....I'll dismantle and check. Seems I'll have to recheck everything.

Thanks again

Rhys

Magic Bus- Number of posts : 1422

Location : -Gateway to the West - St Louis Missouri

Registration date : 2009-12-02

Its interesting that you pressed yours in front to back, mine went in back to front. I did have my axle out of the van and sent it out for a sleeve in each side. I marked mine left and right and re installed it the same way. Does anybody know if it-the axle it self- can be reversed or if it makes any difference? I took a glance at it while it was out and it didn't appear to make any difference.

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

I would have to say the axle is built twisted so that the spindles have the proper caster setting, it needs to go in the right way,,,,,,,,

rhysaccess- Number of posts : 103

Location : Western Australia

Registration date : 2010-02-07

Took the whole lot apart again.....sure had those locking pins in tight! (they're stuffed now due to the subsequent massage of my hammer).

Re-checked the groove on all king pins, Both new and old pretty much identical.

Pins definitely punch in from the front - to the back. (least that's the way the hole is tapered)

Going to closely clean and inspect holes in axle housing. Time to get a little serious with the vernier calipers too. I'll try finding the high spots at either end that is stopping the pins pushing in flush....guessing this is stopping the required locking contact to the king pin grooves.

Failing this I'll get some new locking pins turned up.

Give our universal love of photos - the following one is a better image of how far the pins sit were sitting proud [bastards].

Cheers,

Rhys

Re-checked the groove on all king pins, Both new and old pretty much identical.

Pins definitely punch in from the front - to the back. (least that's the way the hole is tapered)

Going to closely clean and inspect holes in axle housing. Time to get a little serious with the vernier calipers too. I'll try finding the high spots at either end that is stopping the pins pushing in flush....guessing this is stopping the required locking contact to the king pin grooves.

Failing this I'll get some new locking pins turned up.

Give our universal love of photos - the following one is a better image of how far the pins sit were sitting proud [bastards].

Cheers,

Rhys

Magic Bus- Number of posts : 1422

Location : -Gateway to the West - St Louis Missouri

Registration date : 2009-12-02

This is turning out to be an interesting thread. One of my locking pins looks just like that, the other one went on in until flush. Before tackling the job I talked to Dennis at dddiscbrakes. He said that it was normal for the head to mushroom as thats all the further they would go. I also ask him about the axle being swapped left for right, ie if it could be installed backward or not. He said as far as he knew there was no right or wrong. Could be installed either way. All I know is Dennis has been jacking with these econo's for about 40 years, he has 10 of his own and has probably forgotten more about econos than I will ever learn...

Bluelemon- Number of posts : 139

Location : Atlanta, GA

Registration date : 2008-07-10

There is a front and back. You should mark the Econo axle before taking apart. As already noted, the caster (twisted) is cast into the axle. Will be 'difficult' to hold the steering wheel straight and have it return to center if you reverse the ends.

Caster is like a bicycle fork; tilted top to bottom.

The locking pin presses against the groove in the king pin to lock it in place. The hole in tha axle may be the same front or back; makes no difference which way you hammer it in. Most important is that it holds the king pin tight into the axle.

Caster is like a bicycle fork; tilted top to bottom.

The locking pin presses against the groove in the king pin to lock it in place. The hole in tha axle may be the same front or back; makes no difference which way you hammer it in. Most important is that it holds the king pin tight into the axle.

Guest- Guest

Jim is correct, I wasn't sure about the positioning of he axle. Thanks Jim.

Dennis in Oregon

www.dddiscbrakes.com

Dennis in Oregon

www.dddiscbrakes.com

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

rhysaccess- Number of posts : 103

Location : Western Australia

Registration date : 2010-02-07

Ahhhhhh music to my ears.

I bought a battery for my digital verniers today - I'll take some measurements on Monday and post details (we are 12 hours in front on NY here).

Cheers,

Rhys

I bought a battery for my digital verniers today - I'll take some measurements on Monday and post details (we are 12 hours in front on NY here).

Cheers,

Rhys

RodStRace- Number of posts : 3046

Location : Chino Valley

Registration date : 2010-01-21

Those measurements will be a nice resource, but the issue

seems to be that the locking pin does not go deep enough in the hole to lock in the kingpin.

This could be the lock pin dia, and the lock hole dia., but could also be due to the center to center of the kingpin bore to the locking pin bore (plus 90 degrees).

seems to be that the locking pin does not go deep enough in the hole to lock in the kingpin.

This could be the lock pin dia, and the lock hole dia., but could also be due to the center to center of the kingpin bore to the locking pin bore (plus 90 degrees).

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

The problem is that some kingpin bushing kits don't lock the shaft in place,,,,,,,,that's why we want some base dimensions,,,,,,something to reference BEFORE you go and tear everything apart and find out that kit was defective,,,,,we want to compare kits,,,,,,as well as the stock measurements of the pin and kingpin holes in the axle to determine if they are worn or have been modified. And we will need a couple of different axle readings to see if there is any difference in measurements. Then we will be able to determine if the axle is worn or modified or if some of those Bushing Kits are not right. And I want to know about those pin holes,,,,,are they different diameters,,,,if they are then they need to come out the same side they went in,,,,,,,I hear a lot about how hard it is to get those pins out,,,,,,maybe thats because they are trying to force them out the wrong end,,,,,,I need facts,,,,,,,,,,,

rhysaccess- Number of posts : 103

Location : Western Australia

Registration date : 2010-02-07

Howdy all,

Took some measurements tonight.................but am a little unhappy with some of the inconsistencies. Currently blaming the vernier calipers.

Dimensions for the king pin & locking pins should be accurate - the dimensions of the holes don't make a lot of sense. I've got travel for the next week, but here are the results of the checks I made.

Thanks & regards,

Rhys

Took some measurements tonight.................but am a little unhappy with some of the inconsistencies. Currently blaming the vernier calipers.

Dimensions for the king pin & locking pins should be accurate - the dimensions of the holes don't make a lot of sense. I've got travel for the next week, but here are the results of the checks I made.

Thanks & regards,

Rhys

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

Thats a GREAT start,,,,,,,Is the pin and Kingpin new and who made them?

We also need used dimensions. You might be able to use drill bits to measure the pin holes,,,,,,But right now it looks like the pins go in and out from the front of the axle. So lets keep going until we get some consistencies in our readings,,,,,,

We also need used dimensions. You might be able to use drill bits to measure the pin holes,,,,,,But right now it looks like the pins go in and out from the front of the axle. So lets keep going until we get some consistencies in our readings,,,,,,

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

I think the listed stock King Pin Shaft dimension is .741