What do you think?

+55

Vannin Ken

SportVan

chester42

NipRing

Scotts_A100

millwright71

ndjarrett

66 Surf Wagon

Joe Van

Wheelie

Jay 13

Chevboner

Gothboy

sandyvan

dix

the_surfing_guy

southern man

kookykrispy

Space Truckin

vanny

dodge man

thatcherworks

ScottyJones

pan58head

Big W

m1dadio

austinmodhouse

mbasaraba

Lazarusvan

mrclean

LiveWire64

sparky

SDEconoTruck

EconoCarl

Twinpilot001

Nightmoves

BILLS66

sasktrini

Scott

Digz

64chevy

wylee

wacko

RipVanArkie

wideload

DanTheVanMan

mo_1040

itruns

savage

BvrWally

Vanish

G-Man

Kakster

VANagain

donivan65

59 posters

Back to......VANagains NEWest 65 Chevy SportVan Deluxe

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

Speaking of electric fans, I'd been planning on replacing the stock fan with an electric one. I figure all new cars are that way, and lots of hot rods. But then I noticed, there's only an inch and a half or two between the water pump pulley and the radiator in a 1st Gen! No electric fan will squeeze between there. You could put one on either side of the pulley but they'd be pretty small. I know you can put one on the front of the radiator and reverse the polarity so blades spin the other way but then what about the shroud? Seems like a shroud wouldn't have the same effect on the front, like it would block the air from the corners rather than pull it thru.

What do you think?

What do you think?

Digz- Number of posts : 3794

Location : United States Six Lakes MI

Registration date : 2008-05-17

I'm not sure but I think by plumbing the aux trans cooler in before the rad might defeat its purpose, its possible you will get more cooling out of it than you think and end up just reheating it before it goes back to the trans. Something else , and I havent nailed it down, by seperating the cooler from the rad it may make an airspace that restricts airflow to the rad by causing some turbulance for lack of a better word. I know mine is setup differently but I have noticed I created a "high" pressure area between the rad and engine by the hot air shooting up thru the e-brake opening, this made me think of the air dam effect. Just thinking aloud here and maybe something to think about if you have an y issues with cooling, After saying all that it is doing okay in this near 90 temps we are getting right now.

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

VANagain wrote:This weekend I made these spacer blocks to lower my engine 1 inch. This is to level out the whole engine/tranny since there isn't room to get the 700R4's tailshaft as high as it should be. Fortunately that engine crossmember makes it real easy. (Hard to believe the whole engine is hanging on just four bolts!) I bought four longer bolts, 1/2-13 x 2.75", Grade 8 so they're strong enough. And then, since you can see these block when you look in the wheel well, I got a little carried away.

I wanted them to look like stock parts, not just square blocks. Fortunately aluminum is real easy to work with. I picked up two chunks of aluminum: 2" x 1" x 12" for $6 each. The van's frame is 2.5" wide, with 1/4" radius corners, so the 2" blocks sit real nice on the flat bottom of the frame. Then I thought they would look nicer if they were a bit longer than the crossmember width, so I cut them 8.5" long. And I gave the ends a 15 degree angle to match how the frame angles down for the spring shackles. These cuts were made easy by using my table saw. If you use a carbide tipped blade and go slow, aluminum cuts just fine! Then I change the angle of the blade from 15 to 45 degrees so I could chamfer the edges! This was a good headstart on rounding the edges, which I finished with a course file. It took a while, and I worked up quite a sweat, but I really like how they turned out!

Oh, and don't make the same mistake I did. The front of the driver's side block needs to be shorter to allow room for the parking brake "wheel" bracket. Now I have to cut that end off and do some more filing!

So if you had to do it over again would you do anything different, Like thicker blocks?

I picked-up my blocks yesterday, but am concerned that that aluminum will start to give after driving it for a while. I've considered also sliding in a 1/4" piece of steel on the bottom side to help keep it from denting. Am I being paranoid?

G-Man- Mayor

- Number of posts : 30743

Location : Fowlerville, MI

Age : 63

Registration date : 2008-05-06

Question???? You have a 6 cyl , would I have to do something like this with a V8

Digz- Number of posts : 3794

Location : United States Six Lakes MI

Registration date : 2008-05-17

I lowered mine 1-1/2 inches and if I did it over Id drop it more but mostly because of the stance mine ended up with. But the 1 1/2 " allowed the driveline to be super close to the right angles. it also depends on the hieght at the trans mount. this is for the 700R

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

You are right, Digz, the whole idea of adding an auxilliary tranny cooler is to further cool the fluid after it has passed thru the radiator. My way could have ended up heating it back up! So in the end I ran the lines the way everyone says: to the radiator first, then the aux cooler, then back to the tranny.

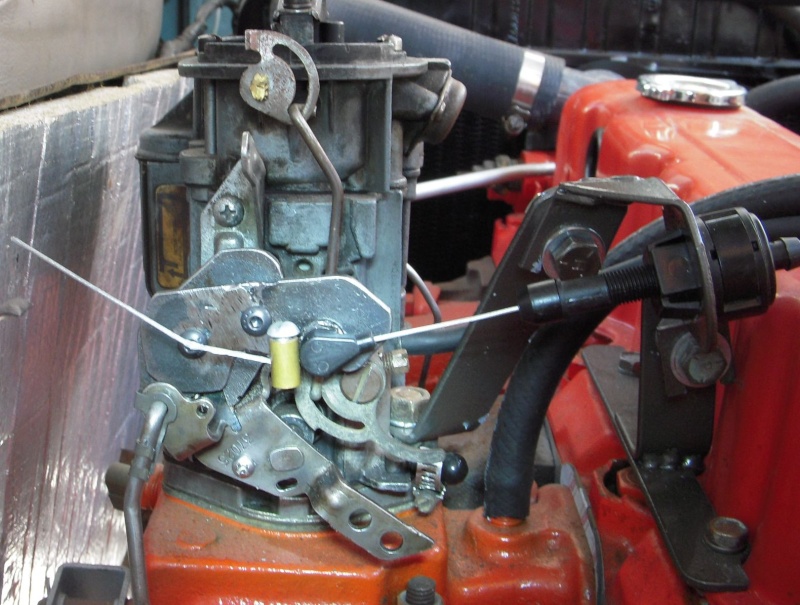

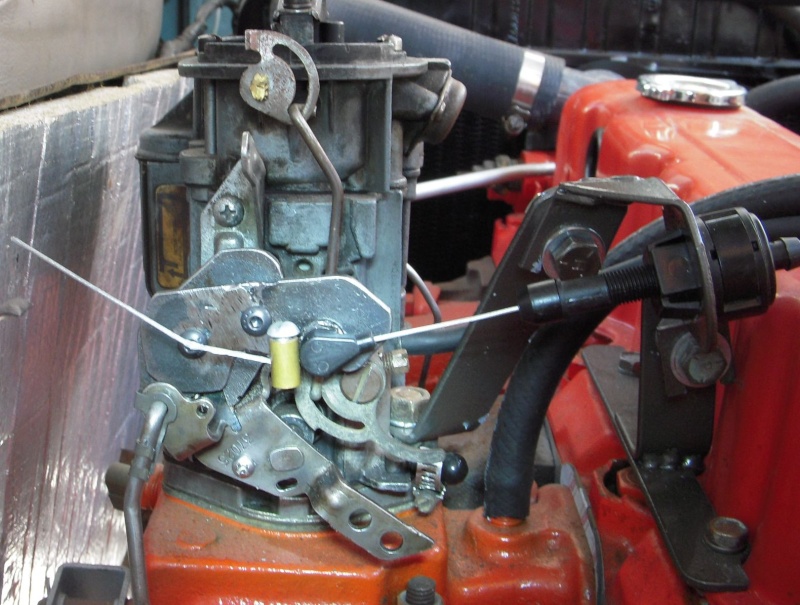

A while back I had fabricated a bracket to attach the TV (throttle valve) cable to the sideways carburetor on my straight six. All seemed fine until Don gave me the choke linkage, which went right where I was planning to mount my bracket!

So yesterday I finished welding up plan B. I attached it to the carb, hooked up the TV cable and then moved on to the next item on the Bowtie Overdrive checklist: Remove tranny pan and make sure the TV plunger was moving properly. Bowtie has pages and pages of documentation on this setup, and I have read thru them many times since I bought this tranny (two years ago!!). It was finally clear in my head. This cable is the only thing that tells the 700R4 tranny what the engine is doing. And it all comes down to one thing: when you put the gas pedal to the floor, the TV plunger in the tranny needs to get pushed all the way in. When the engine is at idle, the plunger come back all the way out. Sounds simple enough, and there are some other subtleties, but really it's a lot like what I had to do to get the van's shifter linkage to move the tranny's shifter the right amount.

But, this morning when I tested this, I found I didn't have enough throw on the cable. It didn't move the plunger far enough! I had based the lever's radius on a 700R4 diagram I'd found online but I needed to my arm longer. And my nice bracket all welded up solid! I looked at the adapters Bowtie makes for popular 4 barrel carbs and saw that they were all adjustable so you could dial in the proper angle and throw. So back to the drawing board! Again! And I had to get it all together and working so I could test the pressure and call Bowtie before they closed at 5:00 today!!

I cut my bracket into two pieces and added a third in between them to allow for two screws that would allow me to make adjustments. I was trying to devise clever slots that would allow me make the lever longer and change the angle. But for started, I just took an educated guess as to a starting point. I drilled two holes, screwed the two parts together, put it on the carb, adjusted the cable and crawled underneath (yet again) to take a look at this plunger. It was 3:30. And hallelujah, it was perfect!!! Here I redesigned it to make it adjustable and I didn't even have to cut any slots! What a relief!

Plunger at idle: Cable at wide-open-throttle:

Cable at wide-open-throttle:  Plunger at wide-open-throttle:

Plunger at wide-open-throttle:

(Also, while I had the pan off, I was instructed to make sure the gears were actually lining up when I moved the shifter (they were) and make sure the dipstick was at the right level (it was).)

I rushed to get the pan back on, poured in 5 quarts of tranny fluid, got the engine fired up and poured in 6 more. Bowtie had sold me a pressure gauge with a 7 foot hose so I could put the gauge where I could read it while in the drivers seat. I chocked all the wheels and put on the parking brake. I got to test my new brakes too while I put it into each gear and wrote down the PSI for each. This was repeated with the TV cable removed, and then with me bringing the RPMs up to 1500 and manually pulling the TV cable all the way out until I felt it stop (plunger fully buried). I had the back tire spinning at one point!

Thankfully the Bowtie guys had not all left early for the Memorial Day weekend when I called at 4:45! Their guy asked me some questions about how I had installed the tranny and then I gave him my numbers. He said they were all perfect! This was fantastic news, after all this time, planning, and work! And now I had his blessing to move on to the road testing this weekend.

(If anyone wants more info or more photos, let me know. I think I am now an expert! Catch me before I forget it all.)

A while back I had fabricated a bracket to attach the TV (throttle valve) cable to the sideways carburetor on my straight six. All seemed fine until Don gave me the choke linkage, which went right where I was planning to mount my bracket!

So yesterday I finished welding up plan B. I attached it to the carb, hooked up the TV cable and then moved on to the next item on the Bowtie Overdrive checklist: Remove tranny pan and make sure the TV plunger was moving properly. Bowtie has pages and pages of documentation on this setup, and I have read thru them many times since I bought this tranny (two years ago!!). It was finally clear in my head. This cable is the only thing that tells the 700R4 tranny what the engine is doing. And it all comes down to one thing: when you put the gas pedal to the floor, the TV plunger in the tranny needs to get pushed all the way in. When the engine is at idle, the plunger come back all the way out. Sounds simple enough, and there are some other subtleties, but really it's a lot like what I had to do to get the van's shifter linkage to move the tranny's shifter the right amount.

But, this morning when I tested this, I found I didn't have enough throw on the cable. It didn't move the plunger far enough! I had based the lever's radius on a 700R4 diagram I'd found online but I needed to my arm longer. And my nice bracket all welded up solid! I looked at the adapters Bowtie makes for popular 4 barrel carbs and saw that they were all adjustable so you could dial in the proper angle and throw. So back to the drawing board! Again! And I had to get it all together and working so I could test the pressure and call Bowtie before they closed at 5:00 today!!

I cut my bracket into two pieces and added a third in between them to allow for two screws that would allow me to make adjustments. I was trying to devise clever slots that would allow me make the lever longer and change the angle. But for started, I just took an educated guess as to a starting point. I drilled two holes, screwed the two parts together, put it on the carb, adjusted the cable and crawled underneath (yet again) to take a look at this plunger. It was 3:30. And hallelujah, it was perfect!!! Here I redesigned it to make it adjustable and I didn't even have to cut any slots! What a relief!

Plunger at idle:

Cable at wide-open-throttle:

Cable at wide-open-throttle:  Plunger at wide-open-throttle:

Plunger at wide-open-throttle:

(Also, while I had the pan off, I was instructed to make sure the gears were actually lining up when I moved the shifter (they were) and make sure the dipstick was at the right level (it was).)

I rushed to get the pan back on, poured in 5 quarts of tranny fluid, got the engine fired up and poured in 6 more. Bowtie had sold me a pressure gauge with a 7 foot hose so I could put the gauge where I could read it while in the drivers seat. I chocked all the wheels and put on the parking brake. I got to test my new brakes too while I put it into each gear and wrote down the PSI for each. This was repeated with the TV cable removed, and then with me bringing the RPMs up to 1500 and manually pulling the TV cable all the way out until I felt it stop (plunger fully buried). I had the back tire spinning at one point!

Thankfully the Bowtie guys had not all left early for the Memorial Day weekend when I called at 4:45! Their guy asked me some questions about how I had installed the tranny and then I gave him my numbers. He said they were all perfect! This was fantastic news, after all this time, planning, and work! And now I had his blessing to move on to the road testing this weekend.

(If anyone wants more info or more photos, let me know. I think I am now an expert! Catch me before I forget it all.)

Last edited by VANagain on Fri May 28, 2010 11:57 pm; edited 1 time in total

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

Regarding lowering the engine, they say the engine and tranny should be level with the ground. So since I couldn't get my tranny up high enough, I figured I better lower the engine, since it's fairly easy to do. I think aluminum is plenty strong, especially because gravity is pulling the crossmember down. The blocks are really just spacers. I suppose there is torque on them. We'll see how they fare.

If I had it to do over again, now that I know where the 700R4 tranny hits the crossmember, I would have rather heated up the crossmember and bent it up out of the way. I just didn't want to take the tranny out again.

Hey Digz, if your stance has your van jacked up in the back, wouldn't lowering the engine make the engine at more of an angle to the ground? Or did you lower the tranny mount even more?

If I had it to do over again, now that I know where the 700R4 tranny hits the crossmember, I would have rather heated up the crossmember and bent it up out of the way. I just didn't want to take the tranny out again.

Hey Digz, if your stance has your van jacked up in the back, wouldn't lowering the engine make the engine at more of an angle to the ground? Or did you lower the tranny mount even more?

Digz- Number of posts : 3794

Location : United States Six Lakes MI

Registration date : 2008-05-17

If it was higher in the back ,,yes it would have ,,but I ended up level and maybe just a tad high in the front, So right, the trannny would have to drop along with the engine. I dont know if they told you at Bowtie but once you have it all working, you can adjust the feel of the shift by moving the cable in your carb bracket 1 click ata a time. Cable housing towards the trans will tighten it up (shifts will feel harder). No wonder when I talked to those guys on the phone they knew about the vans !! I ordered the speedo drive gears and housing from them. What did you do for the lock-up system ?. I am happy with the pressure switch and vacumn switch in line so far.

Nightmoves- Number of posts : 2214

Location : Old Hickory Tenn.

Age : 64

Registration date : 2008-11-17

Vanagain,your TV cable bracket looks good.I'd lil pieces of metal all over the floor.

Dude your gettin real close now.We know 'somebody' whose gonna make a vid of your Sport rolling down the road.heh This has been a good thread on your build.I've learned a bit.

Dude your gettin real close now.We know 'somebody' whose gonna make a vid of your Sport rolling down the road.heh This has been a good thread on your build.I've learned a bit.

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

Nightmoves- Number of posts : 2214

Location : Old Hickory Tenn.

Age : 64

Registration date : 2008-11-17

I'm only catchin about 30 sec of vid 1&2,nuthin on 3(maybe my computer).

My azz is rollin on the floor.It went from 'Alright!' to 'you need to be drivin forward' in 2 seconds.Hillarious.But I did see it move.Good job V A !

My azz is rollin on the floor.It went from 'Alright!' to 'you need to be drivin forward' in 2 seconds.Hillarious.But I did see it move.Good job V A !

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

Yes, it was a big day today! The van is no longer just a decoration in my driveway! We got it to move under its own power! Took a couple drives up and down the block. The tranny worked fine but the engine needs some more tuning. It would backfire when it got under load. Got to check the timing and I still need to rebuild the carb.

Sure was glad that Don could be here for the maiden voyage!! Always the voice of reason. There are many, many smaller tasks to be done -- the fun stuff! -- but where to start? He recommended starting with the wiring. No more hotwiring to start it! Got the 3-wire alternator hooked up so my battery will now charge. And the HEI ignition might enjoy some more oomph rather than running on the battery alone.

Sure was glad that Don could be here for the maiden voyage!! Always the voice of reason. There are many, many smaller tasks to be done -- the fun stuff! -- but where to start? He recommended starting with the wiring. No more hotwiring to start it! Got the 3-wire alternator hooked up so my battery will now charge. And the HEI ignition might enjoy some more oomph rather than running on the battery alone.

Nightmoves- Number of posts : 2214

Location : Old Hickory Tenn.

Age : 64

Registration date : 2008-11-17

Vids are workin now.Y'all are great !Glad to see it runnin & drivin now V A.Looks like tranny worked out good for ya.

High light of vid # 3--- "hold on !"........'To WHAT ?!'

a real Abbot & Costello moment.Heh

High light of vid # 3--- "hold on !"........'To WHAT ?!'

a real Abbot & Costello moment.Heh

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

I sure did fall back into a pile of parts when the trans shifted,,,,,,,,

G-Man- Mayor

- Number of posts : 30743

Location : Fowlerville, MI

Age : 63

Registration date : 2008-05-06

VANagain, It was cool just seeing the smile on your face behind the wheel. Very nice job for sure. Do you think you'll have it ready for you guy's van meet in Sept. ????

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

The van did pretty good for its 1st run,,,,,,,,,now its the little things that need to be done,,,,,,the 3 wire alternator is not hooked up,,,,,as a matter of fact, no wiring is hooked up,,,,,,just a jumper wire to the HEI,,,,,,,the whole doghouse has to be rewired,,,,,,the windshield is cracked but we will try and put in the one that we got from the orange van,,,,,He needs to cut a hole in the floor and put the battery down in there instead of the wonderfull place under the passenger seat that SportVans have them,,,,,,the exhaust hot box bolt has a stripped out stud and you hear that exhaust leaking,,,,,he needs to get it registered,,,,,the right front corner needs repairing or replacing,,,,carb needs to be rebuilt,,,,,,but he has the major things done,,,,,now its just those little things that need to be fixed,,,,,,and there are a lot of them,,,,,,,,

Scott- Number of posts : 1651

Location : Anoka, MN

Age : 54

Registration date : 2008-05-20

VANagain wrote:I think aluminum is plenty strong, especially because gravity is pulling the crossmember down. The blocks are really just spacers. I suppose there is torque on them. We'll see how they fare.

I tossed my PowerGlide and 200-4r up on a table today and checked out the difference in Bellhousing Curves. I don't have any measurements to share, I kind of did the whole thing caveman style, but it was pretty obvious that the spacers are needed. Guess I'm starting to get a little lazy, and almost talked myself into trying the mount first, then if needed adding the spacers later.

Your right VANagain, the aluminum is plenty strong. I checked the numbers printed on the aluminum blocks, Wikipedia has good info on the different types.

Here is what I ended up with:

T6 temper 6061 has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). More typical values are 45,000 psi (310 MPa) and 40,000 psi (275 MPa), respectively.[3] In thicknesses of 0.250 inch (6.35 mm) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties. The famous Pioneer plaque was made of this particular alloy. A material data sheet [4] defines the fatigue limit under cyclic load as 14,000 psi.

Not sure what all that means, but to me it means it won't have any problem taking the torque, or years of engine viberation. I guess it still wouldn't hurt to check the torque after a few hundred miles.

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

I need to make similar spacer blocks (2" tall) to lower my sway bar so it clears the 2nd Gen master cylinder I put in. I see that 2nd Gens have bends in their sway bars to clear it, but I hear their ends are different than 1st Gen's.

Today I made NO progress on the van! After two years of that van sitting on jackstands, my significant other couldn't wait to clean up that half of the driveway! With my help, of course. I spent the rest of the day repairing toilets at my rental!

After two years of that van sitting on jackstands, my significant other couldn't wait to clean up that half of the driveway! With my help, of course. I spent the rest of the day repairing toilets at my rental!

Tomorrow Don's coming over to make sure I'm on task!

Today I made NO progress on the van!

Tomorrow Don's coming over to make sure I'm on task!

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

Is she showing some enthusiasm about your progress,,,,,,,

Digz- Number of posts : 3794

Location : United States Six Lakes MI

Registration date : 2008-05-17

I tried to make the 2nd gen sway bar work on mine, I deemed it not practical.

I cannot remember if it had to do wiith the disc brakes totally I think the shocks were also in the way. If you have the 1st gen bar it would be easiest to make the blocks. IMO

I cannot remember if it had to do wiith the disc brakes totally I think the shocks were also in the way. If you have the 1st gen bar it would be easiest to make the blocks. IMO

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

VANagain- Number of posts : 1048

Location : San Diego, CA

Age : 63

Registration date : 2008-05-16

- Post n°158

Happy Memorial Day!

Happy Memorial Day!

Thanks for posting today's photos Don. And for helping me get past my analysis paralysis. I was working on my wiring as if it would be the final, perfect wire loom. But when you said all we needed at this point was a prototype, that was just what I needed to hear. So what you see pictured here is part of a wire loom from a 70s Impala grafted onto part of the van's original loom. Removed many unecessary wires because I upgraded to a 3-wire (10si) alternator. I can finally start the engine using the key, the battery now gets charged, and the rest of the van has power! We had fun checking to see what lights and stuff worked and what didn't.

We removed my cracked windshield and had intended on putting in a good one, but we found some rust that should be dealt with first along the metal at the bottom. No actual rust holes though, thank goodness, but I want to clean it up.

Later I took a windy ride to see if I could eliminate the backfiring by adjusting the timing while driving. (Try doing that in a muscle car!) Didn't help though. I still need to rebuild my carburetor. But now that I think about it, I maybe my mechanical or vacuum advance aren't working. Don lent me a fancy timing light that allows me to test both. The HEI distributor is out of a junkyard, so who knows.

I did do some nice wiring down by the starter. Don convinced me of the value of adding a Ford-type solenoid (a relay, actually) to shorten the route that energizes the S terminal on the starter's solenoid. Now the Start wire from the key goes to S on the Ford solenoid, which requires less power to energize. This connects the Ford's two big lugs, one wire hooked to the battery terminal on the Chevy solenoid and the other to the S on the Chevy solenoid. Now the power to actuate the Chevy solenoid only has to travel a little over a foot! And using some beefier wire. Plus this solenoid is outside of the doghouse where it should stay cooler.

I found a very thorough explanation of how the charging wiring was done in late 60s Chevrolets. I learned a lot from it. I always thought our van wiring was unique, with the horn relay being used as a junction block. Turns out all Chevys were that way. And it was quite brilliant. And that bus bar on the horn relay turns out to be a perfect place to add other devices.

http://www.madelectrical.com/electricaltech/chevymain1.shtml

Click on "Electrical Tech" for more good info. I like their idea of using relays to give more power to the headlights as well as your dash lights, and ease the burden on your headlight switch. And they tell you everything you need to know (and more) about 3-wire alternators. Note: if you get one for a straight six in a 1st Gen, you'll want it at the 9:00 assembly location. Mine happened to be that way, so the wire plugs are away from the engine. (You can take them apart and change their direction.)

Plus this and other web sites show a different way to use a Ford solenoid so you end up with just one wire going to your starter! It does add one more cable between your battery and your starter but that's how Ford did it.

http://www.allstarperformance.com/downloads/instruction_sheets//ALL76201_Solenoid_Wiring_Kit.pdf

I may switch to this someday. I already made a metal jumper like this. No volltage loss in that connection!

We removed my cracked windshield and had intended on putting in a good one, but we found some rust that should be dealt with first along the metal at the bottom. No actual rust holes though, thank goodness, but I want to clean it up.

Later I took a windy ride to see if I could eliminate the backfiring by adjusting the timing while driving. (Try doing that in a muscle car!) Didn't help though. I still need to rebuild my carburetor. But now that I think about it, I maybe my mechanical or vacuum advance aren't working. Don lent me a fancy timing light that allows me to test both. The HEI distributor is out of a junkyard, so who knows.

I did do some nice wiring down by the starter. Don convinced me of the value of adding a Ford-type solenoid (a relay, actually) to shorten the route that energizes the S terminal on the starter's solenoid. Now the Start wire from the key goes to S on the Ford solenoid, which requires less power to energize. This connects the Ford's two big lugs, one wire hooked to the battery terminal on the Chevy solenoid and the other to the S on the Chevy solenoid. Now the power to actuate the Chevy solenoid only has to travel a little over a foot! And using some beefier wire. Plus this solenoid is outside of the doghouse where it should stay cooler.

I found a very thorough explanation of how the charging wiring was done in late 60s Chevrolets. I learned a lot from it. I always thought our van wiring was unique, with the horn relay being used as a junction block. Turns out all Chevys were that way. And it was quite brilliant. And that bus bar on the horn relay turns out to be a perfect place to add other devices.

http://www.madelectrical.com/electricaltech/chevymain1.shtml

Click on "Electrical Tech" for more good info. I like their idea of using relays to give more power to the headlights as well as your dash lights, and ease the burden on your headlight switch. And they tell you everything you need to know (and more) about 3-wire alternators. Note: if you get one for a straight six in a 1st Gen, you'll want it at the 9:00 assembly location. Mine happened to be that way, so the wire plugs are away from the engine. (You can take them apart and change their direction.)

Plus this and other web sites show a different way to use a Ford solenoid so you end up with just one wire going to your starter! It does add one more cable between your battery and your starter but that's how Ford did it.

http://www.allstarperformance.com/downloads/instruction_sheets//ALL76201_Solenoid_Wiring_Kit.pdf

I may switch to this someday. I already made a metal jumper like this. No volltage loss in that connection!

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

donivan65- Governor

- Number of posts : 12248

Location : San Diego, California

Registration date : 2008-05-12

Today I brought over my old jump seat so I don't have to sit on the battery and VanAgain installed it,,,,,,,and after draining some gas out of his motorcycle to put in the van, I took it for a ride without the windshield, then Rich drove it again. We ran into some distributor problems,,,,,the parts he got for a 2nd edition distributor, like the centrifugal weights, bushings and rotor, were different than his,,,,,,,I'm thinking he has a 1st edition distributor with a 2nd cap and rotor on it,,,,,,