I would like to be able to sit/stand on the roof of my van (pictured in the avatar). I know this is not an original idea. I have already straightened the roof of this van once because somebody else had the same idea.

Well, I climbed onto the roof the other day to sand some of the rust off. At first, I wasn't too surprised or concerned that it buckled again. I can just push it back up with the 2 x 4 right? Then I looked up some old posts on here about roof repair. Oh crap!! I guess the roof on a '66 is not too securely fastened? Bending it back and forth was probably not too good for it: is it now going to come flying off on the freeway?

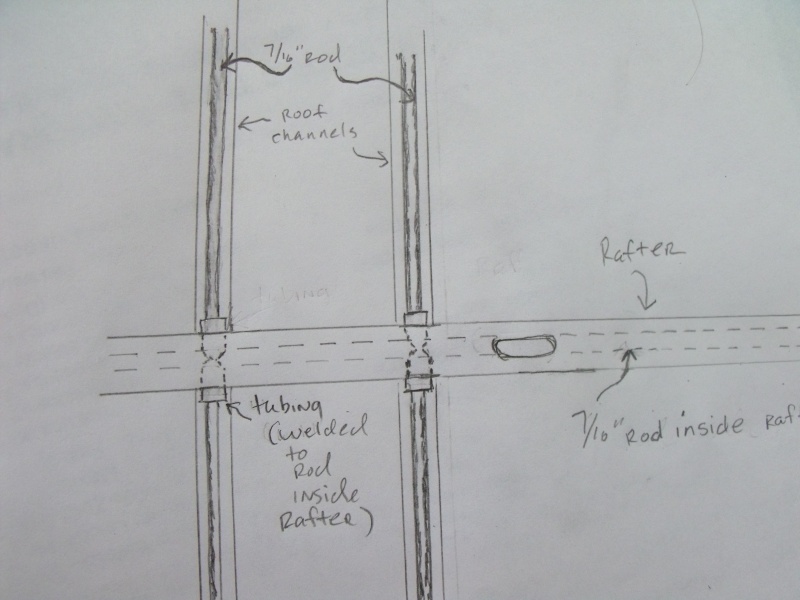

Anyway, my idea for strengthening the roof from the inside involves 7/16" diameter rods: these rods would be placed in the channels that run lengthwise in the roof (they fit perfectly). I would also place rods inside the ribs that run from side to side. I have a little arc welder (70 amp) to possibly put it together.

All of these rods would, of course, have to be bent to conform to the roof (oxy blowtorch or rod bender?), and I would probably use tubing to join them at the points where they intersect. The weight bearing points would be on the sides and the back of the roof, somehow.... I would like to support >300#< on it. Could this work? Pictures to follow, soon as I figure out the new interface. Thanks!

Well, I climbed onto the roof the other day to sand some of the rust off. At first, I wasn't too surprised or concerned that it buckled again. I can just push it back up with the 2 x 4 right? Then I looked up some old posts on here about roof repair. Oh crap!! I guess the roof on a '66 is not too securely fastened? Bending it back and forth was probably not too good for it: is it now going to come flying off on the freeway?

Anyway, my idea for strengthening the roof from the inside involves 7/16" diameter rods: these rods would be placed in the channels that run lengthwise in the roof (they fit perfectly). I would also place rods inside the ribs that run from side to side. I have a little arc welder (70 amp) to possibly put it together.

All of these rods would, of course, have to be bent to conform to the roof (oxy blowtorch or rod bender?), and I would probably use tubing to join them at the points where they intersect. The weight bearing points would be on the sides and the back of the roof, somehow.... I would like to support >300#< on it. Could this work? Pictures to follow, soon as I figure out the new interface. Thanks!