i am tearing down a 230 straight 6 from my 66 gmc van. I AM NOT A MECHANIC (i'm a dentist) and the level of my expertise is 'oh, so that's what a pushrod/rockerarm/lifter/etc. is' , but am trying to be methodical in my mission--have been labelling everything during the tear down. using as a guide an article from chevytrucks.com--it describes a 57 chevy 6 (stovebolt?). so far i have taken the aforementioned parts plus the valves off. here are my findings and questions:

everything looks in good shape, surfaces smooth, not worn or pitted. pushrods straight. everything this article tells me to look for regarding wear comes up a negative. maybe i'm just not looking closely enough, but it all looks pretty dang sweet!

there is carbon buildup everywhere, like i would expect (except excessive on the larger valves of the 2nd, 3rd, and 4th cylinders from the front of the engine).

the symptoms of this vehicle when it last ran 5 years ago were that it lost [/u]alot[u] of oil as it ran, and it never generated much power. one time my wife was following me in another vehicle on a road trip and she wondered why she was having a hard time seeing out of her windshield, only to discover later that it had a fine mist of oil on it! i used to add 1 quart oil for every 150-200 miles. top highway speed was only about 55. i am surprised the 'innards' are not worse off than they appear to be. the van has 91,000 miles on it-almost positive the odometer has not rolled over.

-is it possible that all this engine needs is a good deaning and a 'valve job' or a 'ring job'?

-how do i find a manual for reassembly and where?

-is this 66 straight 6 significantly different than the 57 stovebolt whose article i have been referring to?

-what might be the cause of an engine that looks so good internally (the head, anyway) perform as poorly as describe above?

-what are strightforward practical economical ways to get higher performance out of this engine?

-what do i use to clean up the parts? back on the farm, we used gasoline as a solvent, but i doubt it and a wire brush are the way to achieve the desired result.

-why are lifters called 'hydraulic lifters' when it looks to me like they are activated by riding a cam, and have no 'hydraulic' component?

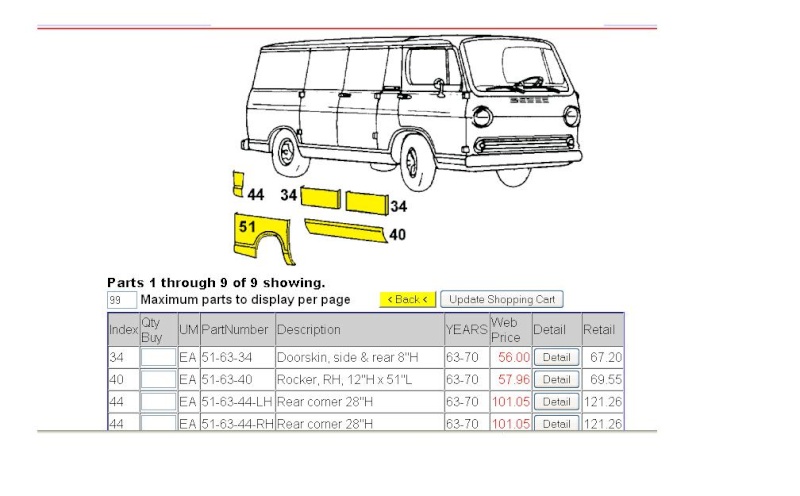

-finally, on the subject of body work--parts on newer vehicles can just be taken off and replaced. how is it done on these old vans--to get the contour right, to get that subtle ledge right, etc. easier with putty than metal, but boy, it seems like it would be an artform. is there a trick or some information i can be referred to?

thanks for all your help and support.

joe

everything looks in good shape, surfaces smooth, not worn or pitted. pushrods straight. everything this article tells me to look for regarding wear comes up a negative. maybe i'm just not looking closely enough, but it all looks pretty dang sweet!

there is carbon buildup everywhere, like i would expect (except excessive on the larger valves of the 2nd, 3rd, and 4th cylinders from the front of the engine).

the symptoms of this vehicle when it last ran 5 years ago were that it lost [/u]alot[u] of oil as it ran, and it never generated much power. one time my wife was following me in another vehicle on a road trip and she wondered why she was having a hard time seeing out of her windshield, only to discover later that it had a fine mist of oil on it! i used to add 1 quart oil for every 150-200 miles. top highway speed was only about 55. i am surprised the 'innards' are not worse off than they appear to be. the van has 91,000 miles on it-almost positive the odometer has not rolled over.

-is it possible that all this engine needs is a good deaning and a 'valve job' or a 'ring job'?

-how do i find a manual for reassembly and where?

-is this 66 straight 6 significantly different than the 57 stovebolt whose article i have been referring to?

-what might be the cause of an engine that looks so good internally (the head, anyway) perform as poorly as describe above?

-what are strightforward practical economical ways to get higher performance out of this engine?

-what do i use to clean up the parts? back on the farm, we used gasoline as a solvent, but i doubt it and a wire brush are the way to achieve the desired result.

-why are lifters called 'hydraulic lifters' when it looks to me like they are activated by riding a cam, and have no 'hydraulic' component?

-finally, on the subject of body work--parts on newer vehicles can just be taken off and replaced. how is it done on these old vans--to get the contour right, to get that subtle ledge right, etc. easier with putty than metal, but boy, it seems like it would be an artform. is there a trick or some information i can be referred to?

thanks for all your help and support.

joe