Realise every one of these disc brake set ups are not like the other!!

I have my master cylinder and Booster mounted behind the rad, about where the engine belts are. This alows for a brake booster.

I had to have an offset 12" long push rod to clear the rad tank. That rod alowed flex and eventually failed.

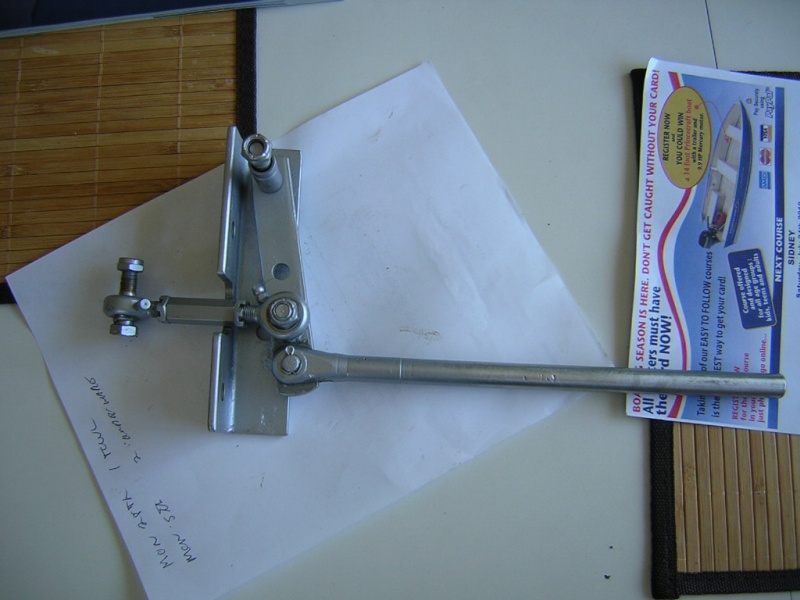

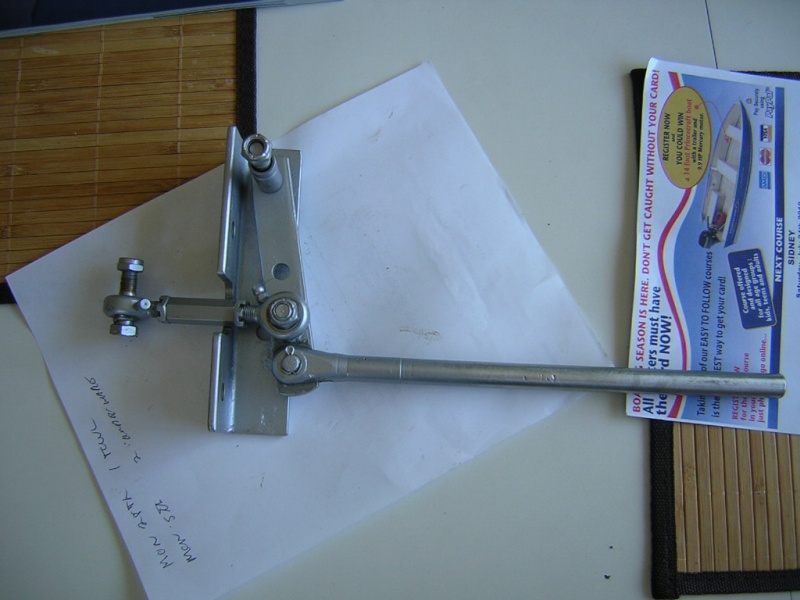

I replaced it with a lever mechanism I built.

My full brakes applied pedal used to be about 3.5" off the floor, which was about half the overall pedal travel.

Now the pedal travel is about 1 and 3/4" giving me an applied high of about 5 and 1/4".

I think that would please alot of you guys with disc brakes complaning of low pedal.

The problen with the low pedal (if all else is correct) is the leverage built into the original brake pedal arm.

If you have or are planning disc brakes, I recomend a master with a bore of not less then 1 + 1/8" , and a double dighram 7" dia booster and increase the leverage of the brake pedal arm by about 1".

The lever I built gives a mechanical advantage of 1". The master usually needs to plunge about 3/4". Now I get the bottom of the pedal arm moves 3/8" and through the lever the booster puch rod moves about 7/8". which translates into the pedal moving 1 + 3/4". It feels great and very solid.

You might be able to build something like I did or build a whole new brake arm like sparky did and add the mechanical advantage right into the pedal or maybe weld an extension to the bottom of your exsisting pedal to relocate the push rod hole lower.(by how much you will have to calculate based on your van).

brakes applied

pedal at rest

M1D

I have my master cylinder and Booster mounted behind the rad, about where the engine belts are. This alows for a brake booster.

I had to have an offset 12" long push rod to clear the rad tank. That rod alowed flex and eventually failed.

I replaced it with a lever mechanism I built.

My full brakes applied pedal used to be about 3.5" off the floor, which was about half the overall pedal travel.

Now the pedal travel is about 1 and 3/4" giving me an applied high of about 5 and 1/4".

I think that would please alot of you guys with disc brakes complaning of low pedal.

The problen with the low pedal (if all else is correct) is the leverage built into the original brake pedal arm.

If you have or are planning disc brakes, I recomend a master with a bore of not less then 1 + 1/8" , and a double dighram 7" dia booster and increase the leverage of the brake pedal arm by about 1".

The lever I built gives a mechanical advantage of 1". The master usually needs to plunge about 3/4". Now I get the bottom of the pedal arm moves 3/8" and through the lever the booster puch rod moves about 7/8". which translates into the pedal moving 1 + 3/4". It feels great and very solid.

You might be able to build something like I did or build a whole new brake arm like sparky did and add the mechanical advantage right into the pedal or maybe weld an extension to the bottom of your exsisting pedal to relocate the push rod hole lower.(by how much you will have to calculate based on your van).

brakes applied

pedal at rest

M1D